In the pursuit of ultimate comfort and performance in stretch fabrics, Air Covered Spandex Yarn has emerged as a revolutionary innovation. Unlike traditional methods, this advanced manufacturing process creates an exceptionally soft, bulky, and high-performing yarn that is redefining quality in activewear, knitwear, and intimate apparel.

This comprehensive guide explores what air covered yarn is, how it’s made, its distinct advantages, and why it has become the preferred choice for premium textile applications.

What is Air Covered Spandex Yarn?

Air Covered Spandex Yarn represents a significant leap in elastomeric yarn technology. It is a specialized structure where a bare spandex (elastane) filament is permanently entangled and covered by one or more strands of staple fibers using a high-speed, compressed air jet. This unique process creates a cohesive, stretchable yarn without the harsh twist of conventional methods, resulting in a final product that is exceptionally soft, bulky, and ideal for high-end fabrics.

The development of air covered yarn is a response to the limitations of older covering technologies like ring spinning and core-spinning. While those methods were effective at creating stretch yarns, they often imparted a harsh hand feel and high torque.

The advent of air-jet texturing technology in the late 20th century was adapted to cover spandex, gaining significant commercial traction over the past two decades. This innovation was driven by market demand for softer, more comfortable, and better-performing stretch fabrics in the premium apparel sector.

The Structure and Manufacturing Process

Understanding the construction of air covered yarn is key to appreciating its superior qualities.

Deconstructing the Components

The yarn is built from two primary components:

- The Core: A bare spandex (elastane) filament that provides the essential stretch and recovery power.

- The Sheath: One or more ends of staple fibers (such as cotton, polyester, viscose, or wool) that wrap around the core. These fibers determine the final fabric’s surface aesthetics, hand feel, and functional properties like moisture-wicking or breathability.

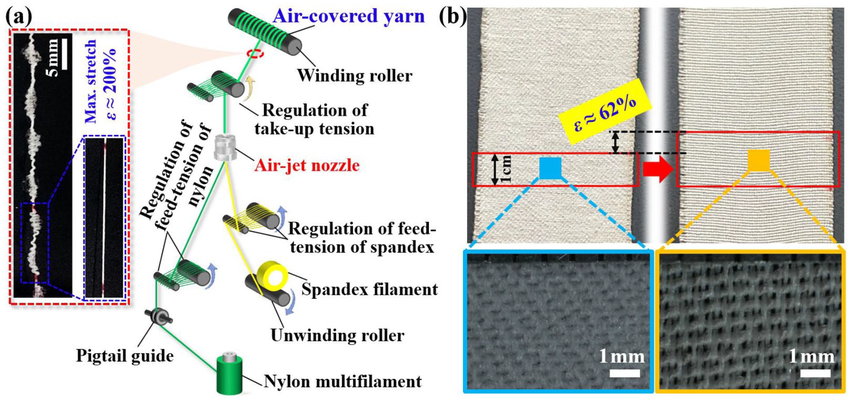

The Air Jet Covering Method: A Step-by-Step Breakdown

The manufacturing process is a marvel of modern textile engineering:

- Feeding: The bare spandex filament and the covering yarns are fed simultaneously under precise tension into an air-jet nozzle.

- Entangling: Inside the nozzle, a controlled stream of compressed air creates a turbulent vortex. This vortex loops and tangles the sheath fibers around the stationary spandex core.

- Binding: The entanglement physically locks the sheath and core together without any mechanical twist, creating a unified, stretchable yarn structure.

- Winding: The finished air covered yarn is then wound onto a package, ready for knitting or weaving.

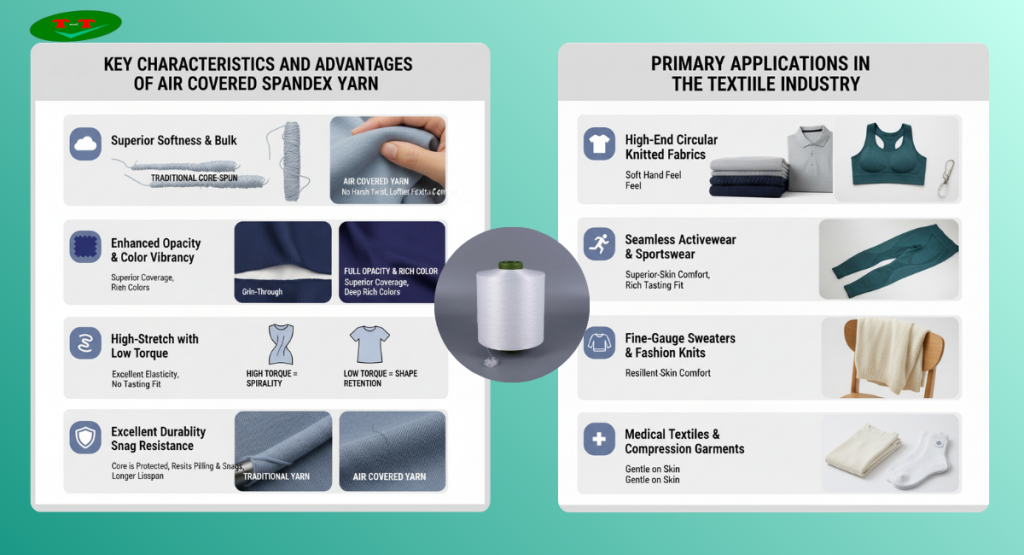

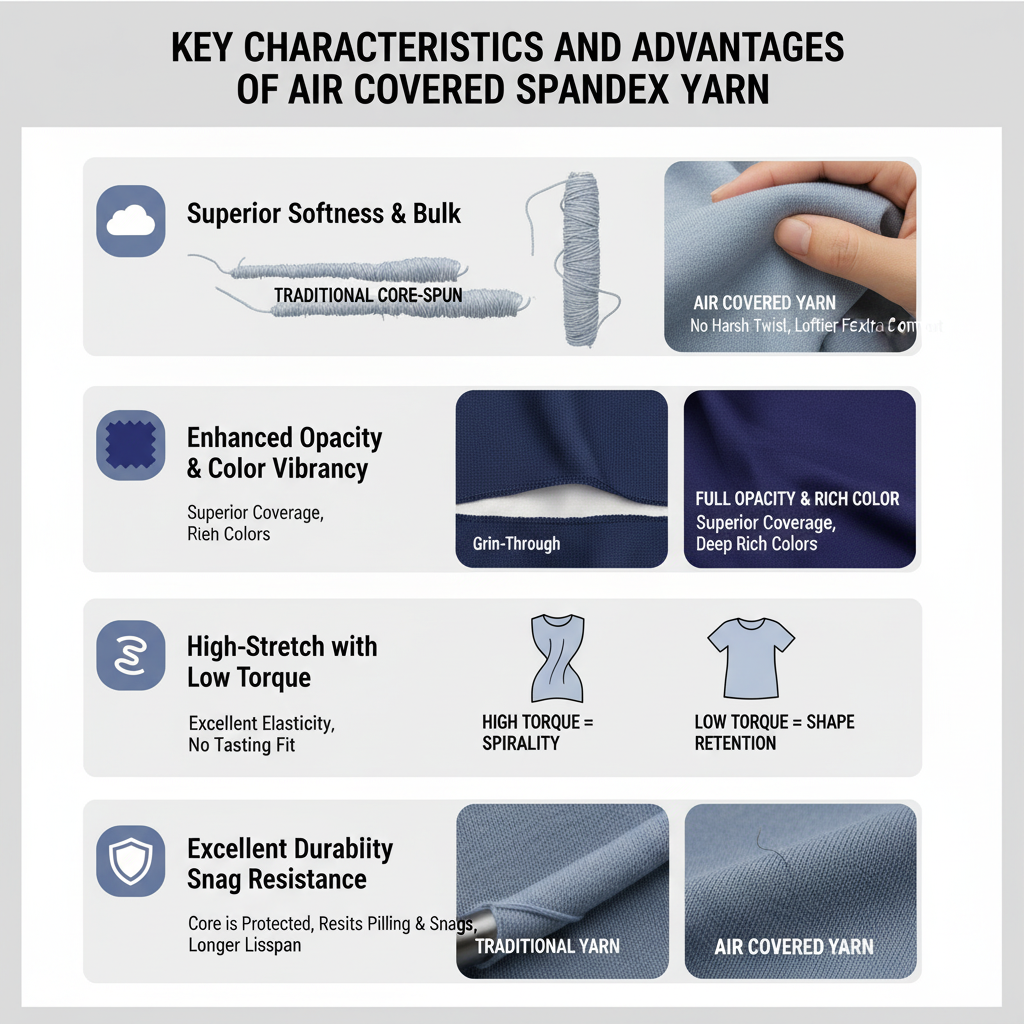

Key Characteristics and Advantages of Air Covered Spandex Yarn

This advanced manufacturing method imparts several distinct benefits that set it apart from other elastomeric yarns.

- Superior Softness and Bulk Without Heaviness: The absence of a tight mechanical twist is the key to its exceptional softness. The air-entangling process creates a loftier, bulkier yarn with more air pockets, resulting in a fabric that feels noticeably softer and more comfortable against the skin, without adding significant weight.

- Enhanced Opacity and Color Vibrancy: The bulkier nature of the yarn provides superior coverage of the spandex core. This eliminates “grin-through”—the visible appearance of the spandex—resulting in fabrics with excellent opacity. Furthermore, the lofty surface provides a better substrate for dyeing, leading to more vibrant and rich colors.

- High-Stretch with Low Torque: Air covered yarn delivers excellent elasticity, allowing for significant stretch and recovery. Crucially, the air-entangled structure has very low torque, which minimizes spirality (the twisting of knitted fabrics) after washing and wearing. This leads to garments that maintain their shape and appearance over time.

- Excellent Durability and Snag Resistance: The entangled sheath firmly locks the spandex core in place, preventing it from being exposed during stretching or abrasion. This structure enhances the yarn’s resistance to snagging and improves the overall durability and longevity of the final fabric.

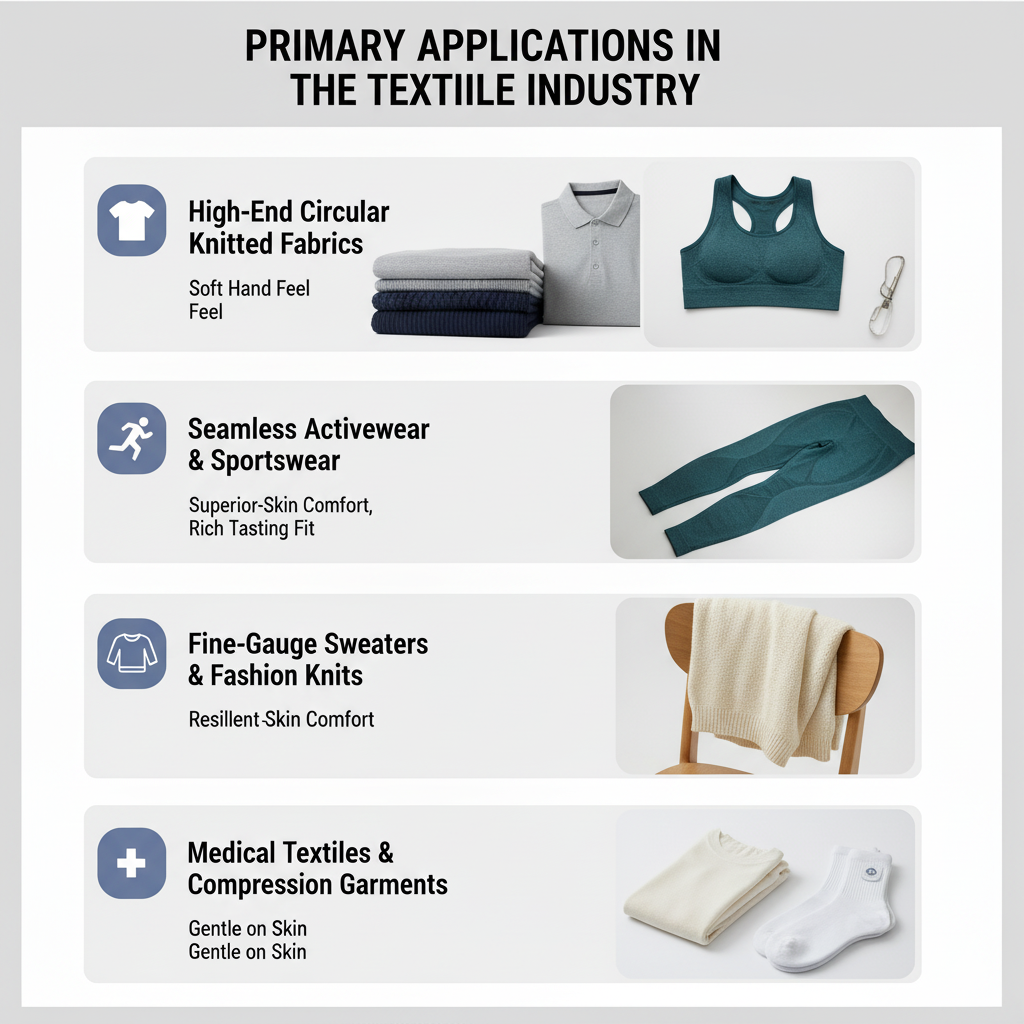

Primary Applications in the Textile Industry

The unique properties of air covered spandex yarn make it ideal for a range of high-value applications.

- High-End Circular Knitted Fabrics: It is extensively used in premium single jersey, rib, and interlock fabrics for T-shirts, polo shirts, and underwear where a soft hand feel and comfortable stretch are paramount.

- Seamless Activewear and Sportswear: The yarn is perfect for seamless knitting technology, used in leggings, sports bras, and athletic tops. Its combination of high stretch, low torque, and superior softness provides a second-skin feel that is essential for performance and comfort.

- Fine-Gauge Sweaters and Fashion Knits: When blended with natural fibers like wool or cotton, it adds a comfortable, resilient stretch to fine-gauge knits and sweaters without compromising their luxurious, soft hand.

- Medical Textiles and Compression Garments: Its softness against the skin and consistent performance make it an excellent choice for medical textiles and compression garments that require prolonged skin contact without causing irritation.

Conclusion

Air Covered Spandex Yarn is more than just an alternative to core-spun yarns; it represents a fundamental upgrade in the production of stretch fabrics. By leveraging air-jet technology to create a softer, bulkier, and higher-performing yarn, it meets the growing demand for premium-quality, comfortable, and durable apparel. For brands and manufacturers targeting the high-end market in activewear, knitwear, and intimate apparel, understanding and utilizing air covered yarn is essential for creating products that stand out in a competitive landscape.

Ready to experience the superior quality of Air Covered Spandex Yarn in your products? Contact our experts today to request samples and discover how our yarn solutions can elevate your fabric collections.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread