For designers and brands creating performance apparel, the fabric choice can make or break a product. When your design demands both rugged durability and dynamic flexibility, Nylon Spandex emerges as a leading contender. But what exactly sets it apart, and when should you choose it over the popular Polyester Spandex?

This guide breaks down the composition, key benefits, and ideal uses of Nylon Spandex, providing a clear comparison to help you make the optimal fabric selection for your next project.

What is Nylon-Spandex Fabric?

Nylon Spandex is a high-performance blended fabric that combines the exceptional strength of Nylon (a polyamide) with the unparalleled elasticity of Spandex (elastane). This synergy creates a material that is both incredibly durable and highly flexible, making it a cornerstone of modern technical apparel. The small addition of Spandex, typically ranging from 5% to 20%, transforms rigid nylon into a dynamic, form-fitting fabric.

- Core Composition Defined: The fabric is primarily composed of Nylon, which forms the backbone and provides structural integrity. Spandex is integrated as a core filament, often wrapped in nylon fibers (core-spun), or plied with them, giving the fabric its signature stretch without compromising its strength.

- Blend Ratios and Performance Impact: The ratio of Nylon to Spandex is critical and dictates the fabric’s behavior. An 85/15 or 90/10 blend offers an excellent balance of durability and stretch for most activewear. A higher spandex content, like 80/20, provides greater compression and stretch for high-impact activities like dancewear or compression garments. Conversely, a 95/5 ratio might be used for applications where minimal stretch is needed, but some recovery is desired.

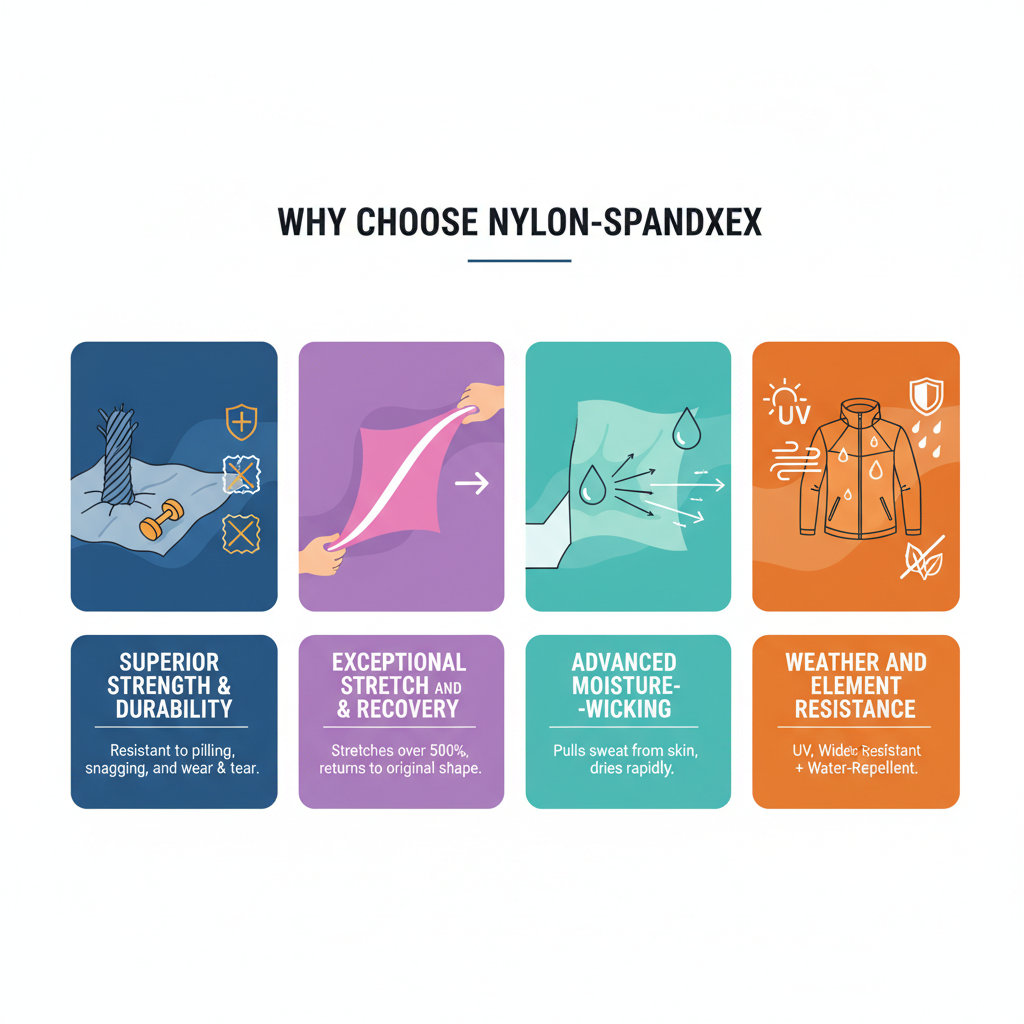

Why Choose Nylon-Spandex — Key Performance Properties

The decision to use Nylon Spandex is driven by its unmatched combination of properties that are essential for performance-driven and comfort-focused apparel.

- Superior Strength and Durability: Nylon is renowned for its high tensile strength and excellent abrasion resistance. This makes Nylon Spandex fabric highly resistant to pilling, snagging, and general wear and tear, ensuring a longer lifespan for the finished garment even under rigorous use.

- Exceptional Stretch and Recovery: The spandex component allows the fabric to stretch extensively—often over 500%—and return to its original shape without becoming baggy or deformed. This superior recovery is crucial for maintaining a consistent fit and compressive feel after repeated use and washing.

- Advanced Moisture-Wicking: Unlike cotton, Nylon is hydrophobic, meaning it repels water. It pulls moisture (sweat) away from the skin to the fabric’s surface, where it can spread out and evaporate rapidly. This quick-drying capability keeps the wearer dry and comfortable during intense physical activity.

- Weather and Element Resistance: Nylon Spandex offers inherent resistance to UV degradation, wind, and mildew. When treated with a Durable Water Repellent (DWR) finish, it also gains water-resistant properties, making it suitable for outdoor and technical jackets.

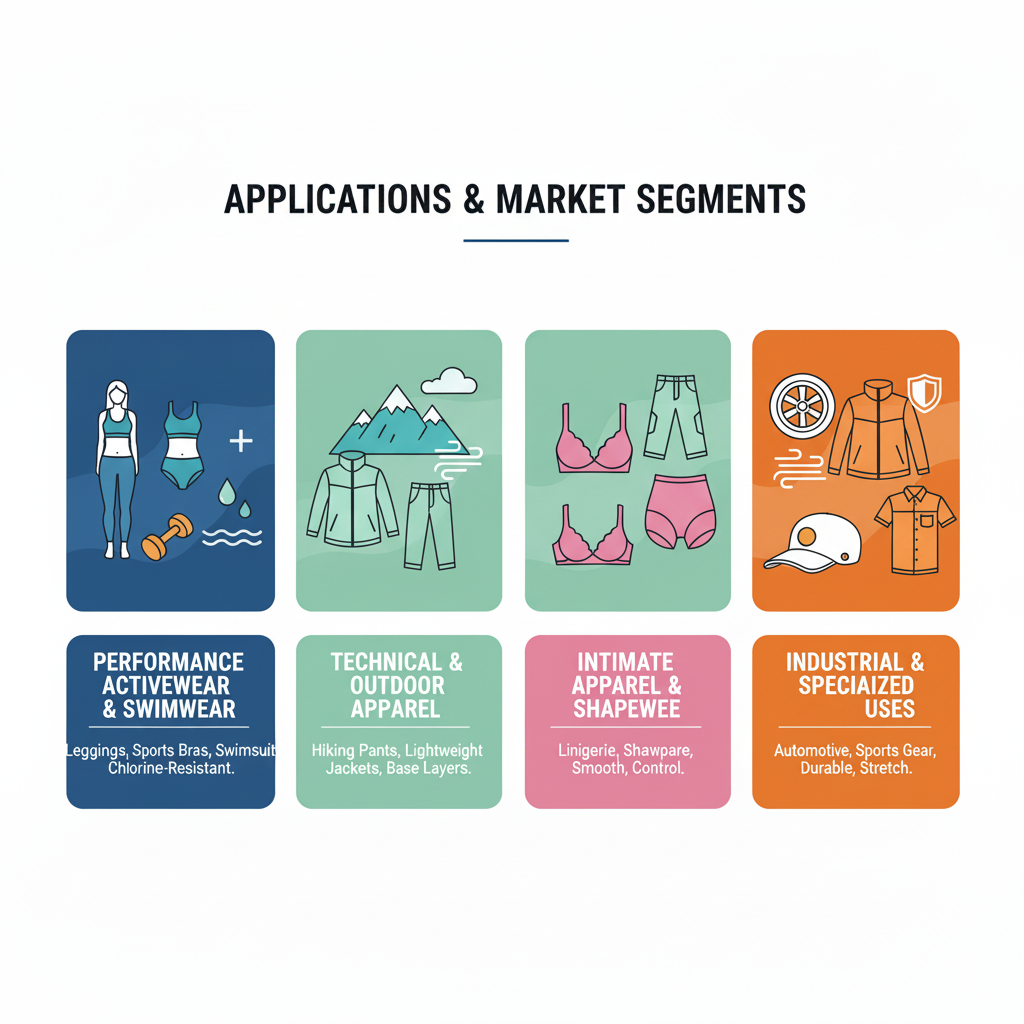

Applications & Market Segments

Thanks to its robust property profile, Nylon Spandex is the material of choice across several key industries.

- Performance Activewear and Swimwear: It is the leading fabric for high-intensity activewear like leggings, sports bras, and cycling shorts. Its chlorine resistance also makes it the definitive choice for durable, form-fitting swimwear.

- Technical and Outdoor Apparel: The fabric’s strength and ability to hold protective finishes make it ideal for hiking pants, lightweight outerwear, and performance layers that require both freedom of movement and resilience.

- Intimate Apparel and Shapewear: The smooth, silky hand feel against the skin, combined with strong control and recovery, makes it perfect for lingerie, shapewear, and bodysuits.

- Industrial and Specialized Uses: Beyond fashion, its durability is leveraged in automotive interiors, sports equipment, and professional uniforms where stretch and long-term wearability are paramount.

Nylon Spandex vs. Polyester Spandex: A Detailed Comparison

Choosing between Nylon and Polyester Spandex depends on the priorities of your application. The following comparison table highlights the key differences to guide your decision.

| Feature | Nylon Spandex | Polyester Spandex |

| Hand Feel & Drape | Softer, silkier, and cooler with a more natural drape. | Drier, slightly crisper hand feel with a less fluid drape. |

| Durability & Abrasion Resistance | Exceptionally strong with superior abrasion and tear resistance. | Durable, but less so than Nylon. More prone to pilling. |

| Moisture Management | Good wicking, fast-drying. Pulls moisture from the skin. | Excellent wicking, very fast-drying. Repels moisture entirely. |

| UV Resistance | Good UV resistance. | Excellent UV resistance, less prone to fading. |

| Shape Recovery | Excellent elasticity and superior shape recovery. | Good elasticity and recovery, but inferior to Nylon. |

| Color Fastness | Holds dyes well, resulting in vibrant colors. | Holds prints excellently, very resistant to environmental fading. |

| Cost | Higher cost. | More cost-effective. |

| Ideal Applications | Swimwear, premium activewear, intimate apparel, dancewear. | Everyday sportswear, hoodies, training apparel, uniforms. |

In summary, choose Nylon Spandex for premium applications where superior softness, exceptional durability, and excellent recovery are non-negotiable. Opt for Polyester Spandex for cost-effective, highly moisture-wicking garments where UV resistance and print longevity are key priorities.

Conclusion

Nylon Spandex fabric is a powerful engineered material that excels in scenarios demanding a perfect balance of comfort, strength, and flexibility. Its superior durability, excellent stretch recovery, and soft hand feel make it the preferred choice for high-end activewear, swimwear, and intimate apparel.

While Polyester Spandex is a fantastic, cost-effective alternative for many applications, Nylon Spandex remains the undisputed champion for projects where performance and longevity are paramount. Understanding these distinctions ensures you select the right fabric to bring your design vision to life with quality and confidence.

Unsure which fabric is the perfect fit for your next collection? Contact our fabric experts today for personalized consultation and access to our premium range of Nylon Spandex and Polyester Spandex fabrics.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread