Choosing the right covered yarn technology is crucial for achieving the desired fabric performance and hand feel. While both Air Covered Yarn (ACY) and Mechanical Covered Yarn (MCY) combine spandex with other fibers, their manufacturing processes create fundamentally different products.

This definitive guide provides a clear, side-by-side comparison to help you understand the key differences and select the optimal yarn for your specific textile application.

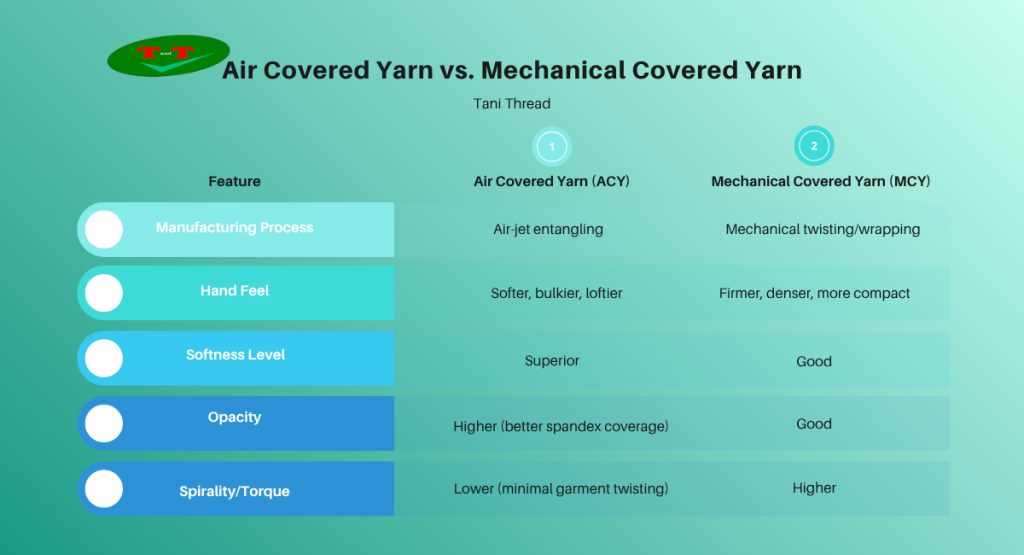

Air Covered Yarn vs. Mechanical Covered Yarn – Side-by-Side Comparison

The core distinction lies in the covering technique: Air Covered Yarn uses turbulent air jets to entangle fibers, resulting in a soft, bulky yarn, while Mechanical Covered Yarn relies on physical twisting or wrapping, producing a firmer, more compact structure. This fundamental difference in manufacturing dictates their performance across all key characteristics.

| Feature | Air Covered Yarn (ACY) | Mechanical Covered Yarn (MCY) |

| Manufacturing Process | Air-jet entangling | Mechanical twisting/wrapping |

| Hand Feel | Softer, bulkier, loftier | Firmer, denser, more compact |

| Softness Level | Superior | Good |

| Opacity | Higher (better spandex coverage) | Good |

| Spirality/Torque | Lower (minimal garment twisting) | Higher |

| Production Speed | Very High | High |

| Durability | Excellent snag resistance, good durability | Excellent durability, may be prone to grin-through |

| Cost | Generally Competitive | Generally Competitive |

| Ideal Applications | Premium knits, seamless activewear, intimate apparel, fine-gauge sweaters | Denim, twills, canvas, upholstery, technical workwear |

Detailed Explanation of Air Covered Yarn and Mechanical Covered Yarn

Air Covered Yarn (ACY) – Air Jet Covering Technology

Air Covered Yarn is produced by feeding a spandex core and one or more cover yarns simultaneously into a high-speed air-jet nozzle. Inside the nozzle, compressed air creates a turbulent vortex that tangles and interlaces the sheath fibers around the elastane core without any mechanical twist.

This process results in a lofty, bulky yarn with a soft hand feel and a high degree of opacity, as the sheath fibers fully envelop the core. The absence of twist also means the yarn has very low torque, which prevents spirality in knitted fabrics.

Mechanical Covered Yarn (MCY) – Mechanical Wrapping Technology

Mechanical Covered Yarn is manufactured using traditional ring spinning or hollow spindle machines that physically twist or wrap the covering yarn around the spandex filament. This method creates a very tight, compact, and strong bond between the core and the sheath.

While this results in excellent durability, the mechanical twisting process makes the yarn denser and firmer to the touch compared to ACY. The high twist can also lead to higher torque, potentially causing knitted garments to twist or skew after washing if not properly managed.

Quality Testing Standards for Air Covered Yarn and Mechanical Covered Yarn

To ensure consistent performance and reliability, both Air Covered Yarn and Mechanical Covered Yarn must undergo rigorous quality testing. The following standards are crucial for evaluating their suitability for different applications:

| Test Parameter | Purpose | Importance for ACY | Importance for MCY |

| Elongation & Recovery | Measures stretch capacity and return to original length | Critical – Determines comfort and fit retention | Critical – Ensures durability in stretched applications |

| Evenness Test | Assesses uniformity of yarn diameter and coverage | High – Affects fabric appearance and surface quality | High – Prevents visual defects and weak spots |

| Tensile Strength | Evaluates breaking strength and durability | Standard – Verifies production quality | High – Essential for heavy-duty applications |

| Torque Measurement | Measures twisting force in the yarn | Critical – Predicts spirality in knitted fabrics | Very High – High torque requires careful handling |

| Grin-Through Test | Checks spandex core visibility when stretched | Standard – Good coverage typically achieved | High – Tight wrapping must prevent core exposure |

These standardized tests ensure that both yarn types meet the specific requirements of their intended applications. For ACY, the focus remains on consistency and low torque, while for MCY, strength and core coverage are paramount. Regular quality verification helps manufacturers maintain product reliability and performance consistency.

Conclusion

Your choice between Air Covered Yarn and Mechanical Covered Yarn ultimately depends on your final product’s requirements. The manufacturing difference—air entanglement versus mechanical wrapping—directly creates their distinct properties.

Choose Air Covered Yarn (ACY) when your priority is superior softness, bulk, and comfort. Its lofty structure and minimal torque make it the ideal choice for high-end applications where a soft hand feel and dimensional stability are critical, such as in premium knitwear, seamless activewear, and intimate apparel.

Choose Mechanical Covered Yarn (MCY) when your priority is maximum durability and a compact structure. Its tight, twisted construction offers great strength, making it well-suited for heavy-duty fabrics like denim, twills, technical workwear, and upholstery that require rugged performance.

By matching the yarn’s inherent characteristics to your application’s demands, you can significantly enhance the quality, performance, and consumer appeal of your textile products.

Still unsure which yarn technology is right for your project? Contact our technical experts today for a personalized consultation and receive complimentary yarn samples to test for yourself.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread