Understanding the fundamental difference between single yarn and double yarn is crucial for selecting the right material for any textile project. While both serve as building blocks in fabric production, their distinct structures lead to dramatically different characteristics in strength, appearance, and application.

This comprehensive guide breaks down the definitions, structures, and practical implications of both yarn types to help manufacturers and designers make informed decisions.

What Is Single Yarn?

Single yarn, also known as single-ply yarn, represents the most basic form of yarn structure. It is created by twisting together staple fibers or filaments into a continuous strand through a single spinning process. This fundamental construction makes it the starting point for more complex yarn types and one of the most widely used yarns in textile manufacturing.

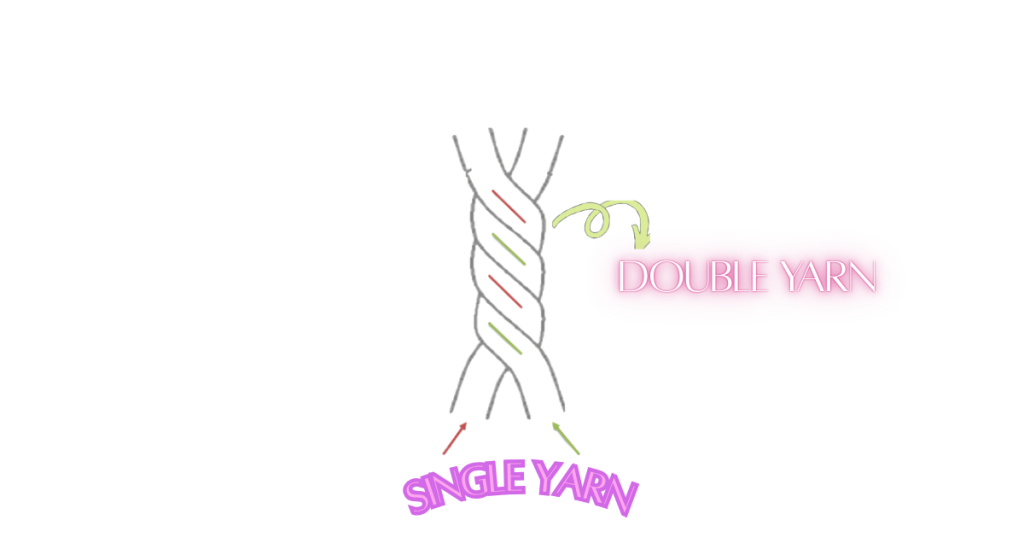

The structure of single yarn consists of fibers twisted together in one direction (either S-twist or Z-twist) to create cohesion and strength. The degree of twist significantly affects the yarn’s properties—higher twist results in stronger, harder yarn, while lower twist produces softer, more bulky yarn. This simple twisted structure gives single yarn its characteristic appearance and forms the foundation for all ply yarn constructions.

What Is Double Yarn?

Double yarn, commonly referred to as 2-ply yarn, is created by twisting two or more single yarns together in the opposite direction of their original twist. This plying process transforms individual single yarns into a more sophisticated composite yarn that offers enhanced performance characteristics and superior quality for specific applications.

The structure of double yarn involves twisting two single yarns together in the direction opposite to their original twist. This counter-twisting action creates a balanced yarn structure that significantly reduces curling tendency and improves dimensional stability. The plying process also allows for the combination of different fiber types or colors within the same yarn, creating unique aesthetic effects and functional properties.

Single Yarn vs. Double Yarn – Detailed Comparison

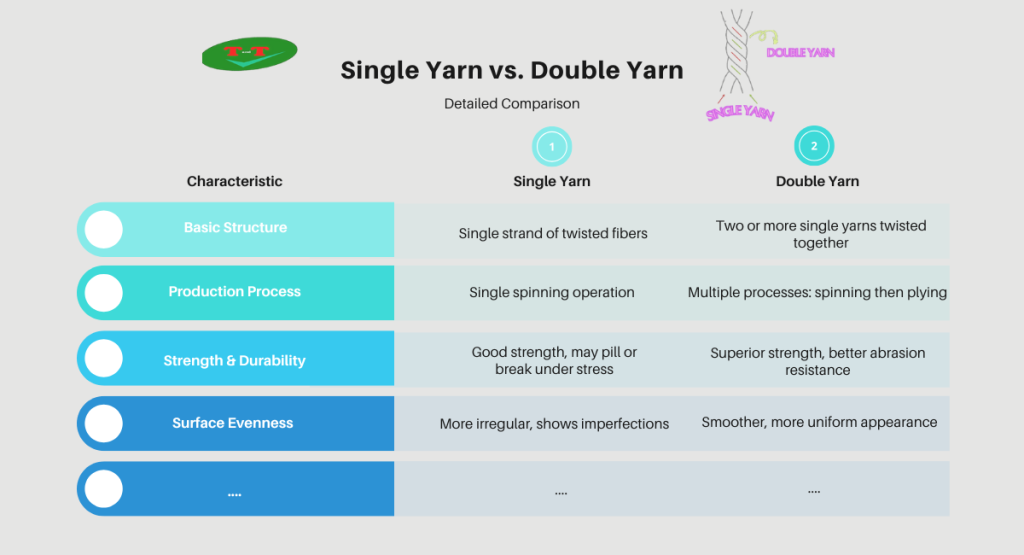

The fundamental distinction lies in their construction: single yarn consists of a single twisted strand of fibers, while double yarn comprises two or more single yarns twisted together. This structural difference creates a clear divergence in performance characteristics and ideal applications.

| Characteristic | Single Yarn | Double Yarn |

| Basic Structure | Single strand of twisted fibers | Two or more single yarns twisted together |

| Production Process | Single spinning operation | Multiple processes: spinning then plying |

| Strength & Durability | Good strength, may pill or break under stress | Superior strength, better abrasion resistance |

| Surface Evenness | More irregular, shows imperfections | Smoother, more uniform appearance |

| Cost Efficiency | More economical, faster production | Higher cost due to additional processing |

| Weight & Thickness | Lighter weight for same yarn count | Heavier and thicker construction |

| Common Applications | Basic fabrics, filling yarns, pile fabrics | Knitting yarns, weaving warp yarns, premium fabrics |

| Typical Yarn Count Range | Wider range, from very fine to coarse | Generally medium to coarse counts |

Textile Terminology Related to Single Yarn and Double Yarn

Understanding these essential terms provides deeper insight into yarn construction and helps in making informed material selections:

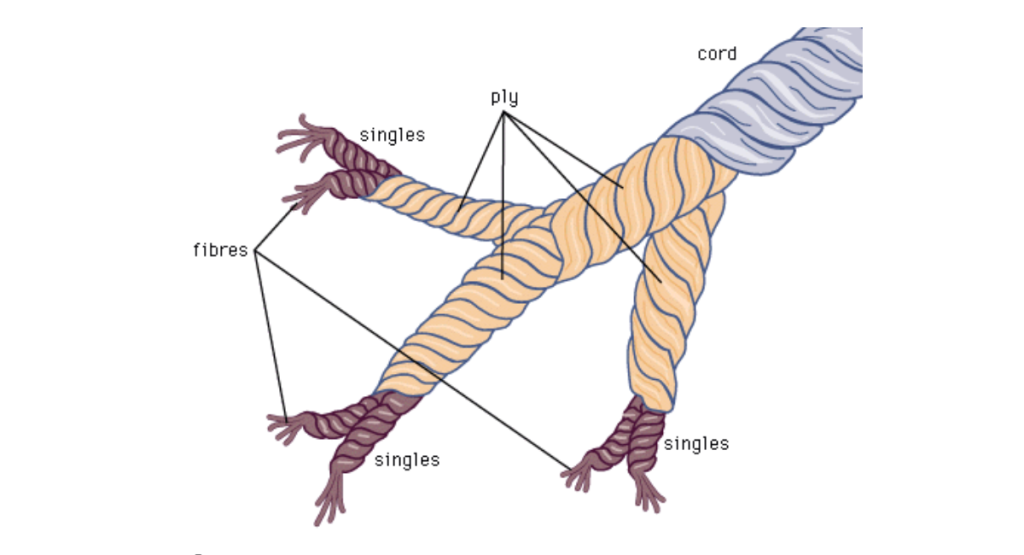

- Ply: Refers to the number of single yarns twisted together to form a plied yarn. For example, double yarn is 2-ply yarn, while triple yarn would be 3-ply. You’ll encounter this term in yarn specifications, fabric descriptions, and quality standards. When selecting yarn for knitting or weaving, the ply count directly indicates the yarn’s thickness and durability.

- Yarn Count: A numerical expression that defines the fineness or coarseness of yarn. Common systems include Ne (English count) and Tex. For instance, a 40Ne yarn is finer than a 20Ne yarn. This measurement appears in technical datasheets, purchase orders, and fabric specifications. Manufacturers use yarn count to calculate fabric density and weight, while designers use it to predict fabric hand feel and drape.

- Twist Direction: Describes the spiral orientation of fibers in yarn:

- S-twist: Fibers spiral upward to the left, like the central part of the letter “S”

- Z-twist: Fibers spiral upward to the right, like the central part of the letter “Z”

You’ll find this terminology in weaving manuals and yarn analysis reports. The twist direction affects fabric appearance and performance – weavers often use opposite twist directions for warp and weft to create balanced fabrics.

Conclusion

Choosing between single yarn and double yarn depends entirely on the requirements of your final product. Single yarn offers cost-effectiveness and simplicity, making it ideal for basic fabrics, filling applications, and projects where budget constraints are paramount. Its straightforward production process and lighter weight make it suitable for everyday textiles and mass-produced items.

Double yarn, with its superior strength, enhanced durability, and premium appearance, is the clear choice for high-performance applications, luxury fabrics, and products requiring exceptional longevity. The additional processing cost is justified by the improved quality and performance characteristics that elevate the final product.

Understanding these fundamental differences enables textile professionals to make strategic decisions that align with their quality requirements, performance needs, and budget considerations, ultimately leading to better products and more satisfied end-users.

Need expert guidance in selecting the right yarn for your specific application? Contact our textile specialists today for personalized recommendations and access to our comprehensive range of single and double yarn solutions.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread