From the yoga studio to the office, stretch knit fabrics have revolutionized how we experience comfort and style in clothing. But what exactly makes these fabrics so versatile, and how do you choose the right one for your project?

This comprehensive guide demystifies stretch knit fabrics, exploring their unique properties, different types of stretch, and practical applications to help you make informed decisions for your apparel or product line.

What Is Stretch Knit Fabric?

Stretch knit fabric combines the natural flexibility of knitted construction with engineered elasticity. Unlike woven fabrics, knits are built from interlocking loops that naturally provide give and recovery. When elastane fibers like spandex are added, this flexibility becomes enhanced and controlled, creating materials that move with the body while maintaining their shape. This fundamental characteristic makes stretch knit fabric essential for modern apparel that prioritizes both comfort and performance.

Key Properties of Stretch Knit Fabric

- Exceptional Elasticity and Recovery: This is the defining characteristic of stretch knit fabrics. The integration of elastane fibers (like spandex) allows the material to extend significantly—anywhere from a subtle 15% to an impressive 200% or more—under tension. Crucially, the fabric possesses a powerful “memory” enabling it to spring back to its original dimensions once the tension is released. This robust recovery mechanism is what prevents the garment from becoming permanently deformed or baggy after repeated wear, ensuring a consistent fit over time.

- Superior Comfort and Flexibility: The very structure of a knit—composed of interlocking loops—creates a fabric that is inherently pliable and moves with the body, not against it. This translates into unparalleled freedom of movement and a non-restrictive fit that molds to the wearer’s form. Unlike stiffer woven fabrics, stretch knits eliminate the feeling of constriction, making them ideal for everything from all-day loungewear to high-intensity athletic activities where a full range of motion is essential.

- Wrinkle Resistance: The looped construction and inherent elasticity of knit fabrics make them naturally resistant to creasing and wrinkling. When bent or compressed, the loops can shift and absorb the stress rather than forming a sharp crease. This means garments maintain a smoother, more polished appearance with minimal upkeep, often requiring little to no ironing, which enhances their practicality for travel and daily wear.

- Breathability and Moisture Management: Many knit constructions are naturally breathable due to the tiny spaces between the loops that allow for air circulation. Furthermore, when synthetic fibers like polyester or nylon are used in the blend, the fabric can be engineered for advanced moisture management. These technical blends are designed to wick perspiration away from the skin to the fabric’s surface, where it can evaporate rapidly. This keeps the wearer dry and comfortable during physical exertion or in warm environments.

- Durability & Abrasion Resistance: The combination of a resilient knitted structure and the incorporation of strong synthetic and elastic fibers results in a remarkably durable material. The loops in the knit construction can distribute stress more evenly than the straight yarns in a woven fabric, reducing the likelihood of tearing. This, combined with the strength of fibers like nylon and the fatigue-resistance of spandex, allows the fabric to withstand the rigors of repeated stretching, washing, and wear without compromising its integrity.

- Color Fastness: Modern dyeing techniques and fiber blends ensure that stretch knit fabrics exhibit excellent color fastness. This means the colors resist fading from washing, exposure to sunlight (UV radiation), and perspiration. Solution-dyed synthetic fibers, where the color is embedded within the fiber itself during production, offer particularly superior resistance to fading compared to traditionally dyed fabrics. This property is essential for maintaining the vibrant appearance of athletic wear, swimwear, and everyday apparel, ensuring the garment looks new for longer.

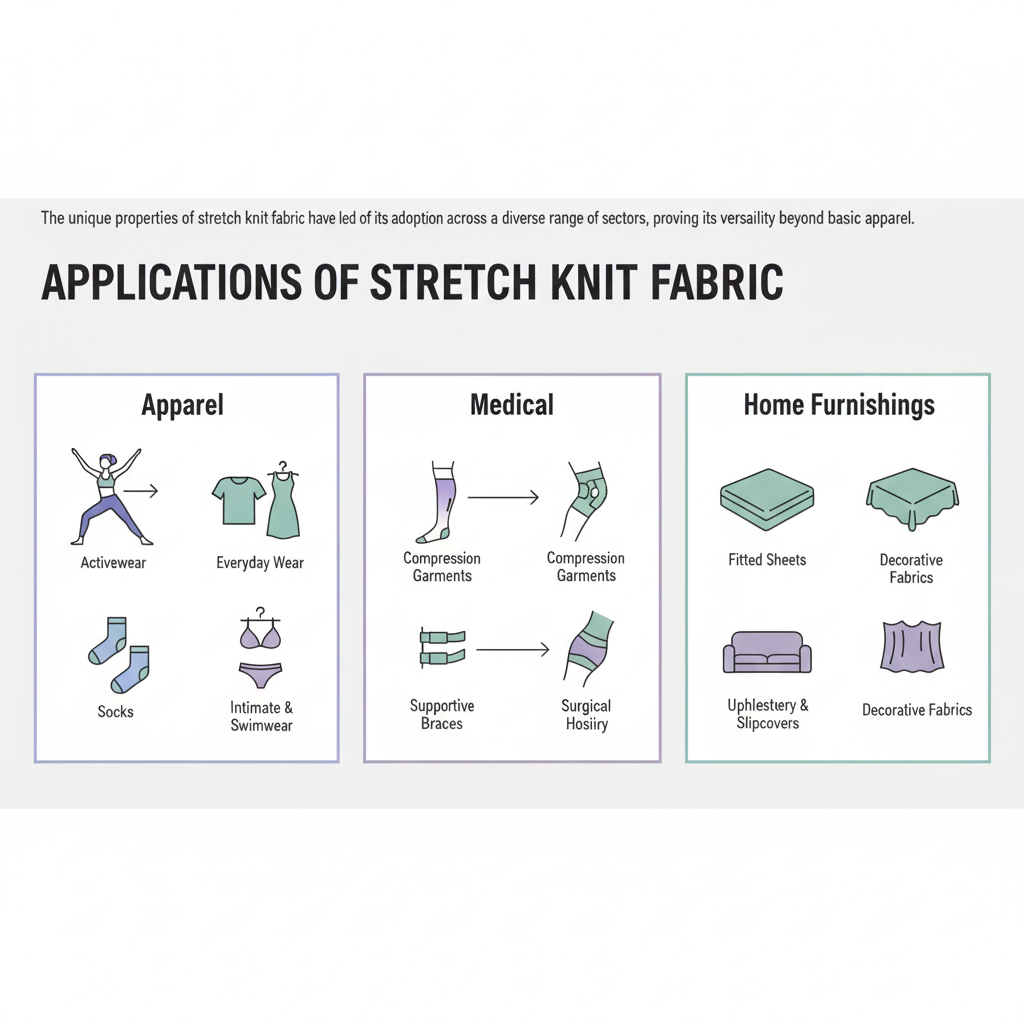

Applications of Stretch Knit Fabric in Apparel & Industry

The unique properties of stretch knit fabric have led to its adoption across a diverse range of sectors, proving its versatility beyond basic apparel.

- Apparel: This is the most prominent application area. In activewear, such as leggings and sports bras, the 4-way stretch and recovery provide muscle support and unrestricted movement. For everyday wear like t-shirts and dresses, it introduces “comfort stretch” that improves fit and ease. In intimate apparel and swimwear, it is essential for creating a secure, contoured, and comfortable fit that withstands movement and exposure to water. Even socks benefit from the gentle compression and fit retention that knits provide.

- Medical: The controlled elasticity of stretch knits is critical in the medical field. Compression garments rely on specific stretch and recovery properties to apply therapeutic pressure, aiding in recovery from surgeries or managing conditions like lymphedema. Surgical hosiery and supportive braces use these fabrics to provide stabilization and compression to joints and tissues, enhancing patient comfort and mobility during recovery.

- Home Furnishings: The practical benefits of stretch knit fabric have found a valuable place in the home. Fitted sheets made from stretch knits are easier to put on and maintain a taut, wrinkle-resistant surface on the mattress. In upholstery, these fabrics allow for tailored covers that snugly fit furniture with complex curves, while their durability stands up to regular use. Their flexibility and drape also make them suitable for certain types of decorative fabrics and stretchable slipcovers.

Lycra vs Spandex vs Elastane: What’s the Difference?

The terms Lycra, spandex, and elastane often cause confusion, but they essentially refer to the same synthetic fiber known for its exceptional elasticity. The distinction lies primarily in regional terminology and branding rather than chemical composition or fundamental properties. All three terms describe a polyurethane-based fiber that can stretch over 500% and recover to its original shape.

Comparison Table: Lycra vs Spandex vs Elastane

| Term | Origin | Primary Usage | Keynote |

| Spandex | North America | Common term in the United States and Canada | The generic term widely understood in the Americas |

| Elastane | Europe & Asia | Common term in Europe, Australia, and most international markets | The international ISO standard term for the fiber |

| Lycra | Brand Name | Global, used as a brand name by The LYCRA Company | A branded fiber that often includes quality certifications |

Why These Terms Matter in Stretch Knit Fabric

Understanding these terminological differences is crucial for effective global sourcing and manufacturing. A fabric described as “cotton-spandex” in North America may be labeled “cotton-elastane” in European markets, yet contain the same essential fiber. The Lycra brand often signifies additional quality assurance and specific performance certifications, which can be important for manufacturers seeking consistent results and marketable benefits in their finished products.

1-Way vs 2-Way vs 4-Way Stretch Fabrics: Key Differences and Applications

Understanding the direction and degree of stretch is fundamental to selecting the right fabric for any application. These categories define how a fabric moves and performs under tension, directly impacting the comfort, fit, and functionality of the final product.

What Is 1-Way Stretch Fabric?

- Quick Definition: Fabric that stretches in only one direction, typically along the width (weft).

- Key Characters: Provides comfort and ease of movement in one direction but is stable in the other. Offers minimal recovery compared to multi-directional stretches.

- Common Uses: Stretch denim, waistbands, woven shirts with a slight comfort stretch.

What Is 2-Way Stretch Fabric?

- Quick Definition: Fabric that stretches in two directions, most commonly along the width (weft).

- Key Characters: Common in many basic knits like jersey. Provides good comfort stretch but may bag out with time if not blended with a strong recovery fiber like spandex.

- Common Uses: T-shirts, polo shirts, basic leggings, and casual dresses.

What Is 4-Way Stretch Fabric?

- Quick Definition: Fabric that stretches in both directions: width (weft) and length (warp).

- Key Characters: Offers maximum flexibility, mobility, and recovery. It moves with the body in all directions and is essential for compression and form-fitting garments.

- Common Uses: High-performance activewear (yoga pants, compression gear), swimwear, and sophisticated shapewear.

How to Choose the Right Stretch Level for Your Application

- 1-Way Stretch: Choose for structure with comfort. Ideal for adding slight flexibility to woven-style garments like jeans, trousers, and blouses without losing their shape. Best for waistbands and structured components.

- 2-Way Stretch: Choose for everyday comfort. Perfect for basic knitwear like t-shirts, casual dresses, and loungewear where general movement and comfort are key. The most common and cost-effective option.

- 4-Way Stretch: Choose for maximum performance. Essential for activewear, swimwear, and compression garments that require unrestricted movement in all directions, a precise fit, and superior recovery to prevent sagging.

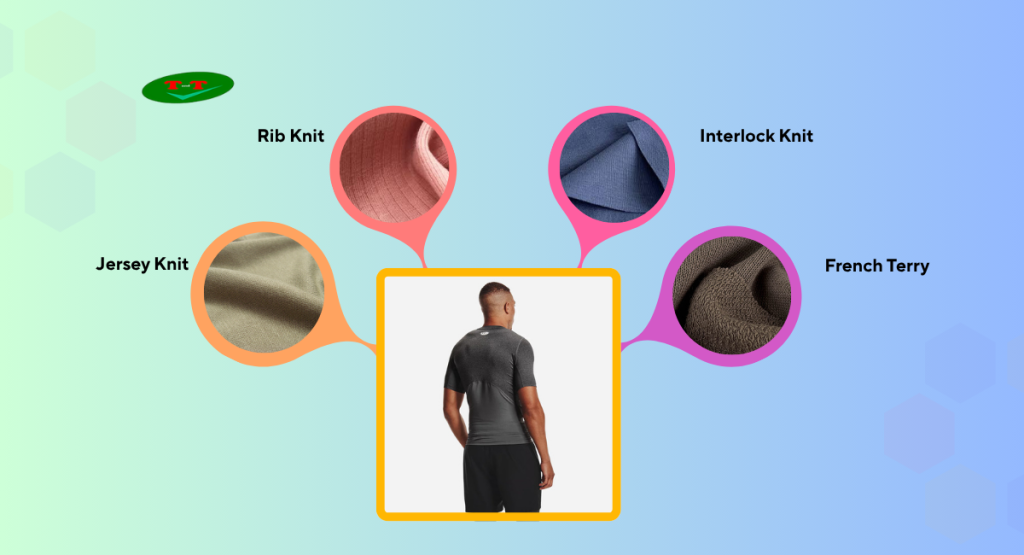

Types of Stretch Knit Fabric

The world of stretch knit fabrics encompasses various constructions, each with unique characteristics that make them suitable for specific applications. Understanding these different types enables better selection for particular product requirements and performance needs.

| Type | Structure | Properties | Applications | Pros | Cons |

| Jersey Knit | Basic knit with smooth face and slight ribbed back | Soft, good drape, 2-way stretch, edges may curl | T-shirts, dresses, lightweight tops | Inexpensive, versatile, comfortable | Prone to curling and runs |

| Rib Knit | Vertical ribs on both sides from knit/purl stitches | Highly elastic width-wise, excellent recovery, thicker | Cuffs, collars, neckbands, sweaters | Very stretchy, durable | Heavy, uses more yarn |

| Interlock Knit | Double-knit, two jersey layers interlocked | Stable, smooth both sides, less elastic than rib | Premium t-shirts, polo shirts, athleisure | Doesn’t curl, good drape, stable | Less stretchy, heavier |

| French Terry | Loops on one side, soft pile on other | Absorbent, breathable, comfortable, 2-way stretch | Hoodies, sweatpants, loungewear | Cozy, absorbent, great for casual | Looped back can snag |

Conclusion

Stretch knit fabric represents a perfect synergy of comfort, durability, and technical performance that has transformed modern textiles. Its unique properties enable creations that move with the body while maintaining structural integrity across countless applications.

For business decision-makers, selecting the appropriate stretch knit requires careful consideration of your target market and product objectives. The choice between different stretch types and knit constructions should align with your brand positioning, price points, and performance requirements. Understanding these variables enables strategic sourcing that balances cost with quality.

FAQ About Stretch Knit Fabric

Does 95% polyester and 5% elastane stretch?

Yes, significantly. The 5% elastane provides excellent stretch and recovery, making this a durable blend ideal for activewear and swimwear that requires both flexibility and shape retention.

How to sew stretch knit fabric?

Use a ballpoint needle to prevent snagging and a narrow zigzag or stretch stitch to allow seams to move with the fabric without breaking.

How to fix stretched knit fabric?

Gently wash in cool water and lay flat to dry. Steam can help elastic fibers partially recover their shape through controlled heat application.

What is the best stitch for stretch knit fabric?

A narrow zigzag stitch is most accessible, while a lightning bolt stitch or serger/overlocker provides professional results for stretch seams.

We provide high-quality covered yarn – the core material for creating stretch knit fabric with superior elasticity and durability. Contact our experts today for personalized recommendations and premium yarn solutions.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread