Single covered yarn represents a fundamental category of elastomeric yarns that combines stretch performance with manufacturing efficiency. As a versatile solution between bare spandex and more complex double covered yarns, it serves numerous applications across the textile industry. Understanding its unique construction and characteristics helps manufacturers select the right yarn for their specific fabric requirements and performance needs.

What Is Single Covered Yarn?

Single covered yarn features a straightforward two-component structure where a single layer of covering yarn is helically wrapped around an elastane core. The manufacturing process involves feeding the spandex filament and covering yarn through a covering machine that twists the outer layer around the core in one direction, typically at a specific wraps per inch (WPI) ratio. This creates a cohesive yarn structure where the spandex core provides elasticity while the sheath yarn determines surface characteristics and protection.

Properties

The properties of single covered yarn balance elasticity with practical functionality:

- Moderate Stretch Capacity: Provides reliable elasticity while maintaining fabric integrity

- Good Recovery: Offers consistent return to original length after stretching

- Visible Core: May exhibit slight “grin-through” under maximum tension

- Moderate Torque: Exhibits some twisting tendency due to single-direction wrapping

- Cost-Effective: More economical than double covered alternatives

- Lightweight Construction: Maintains minimal weight while adding stretch functionality

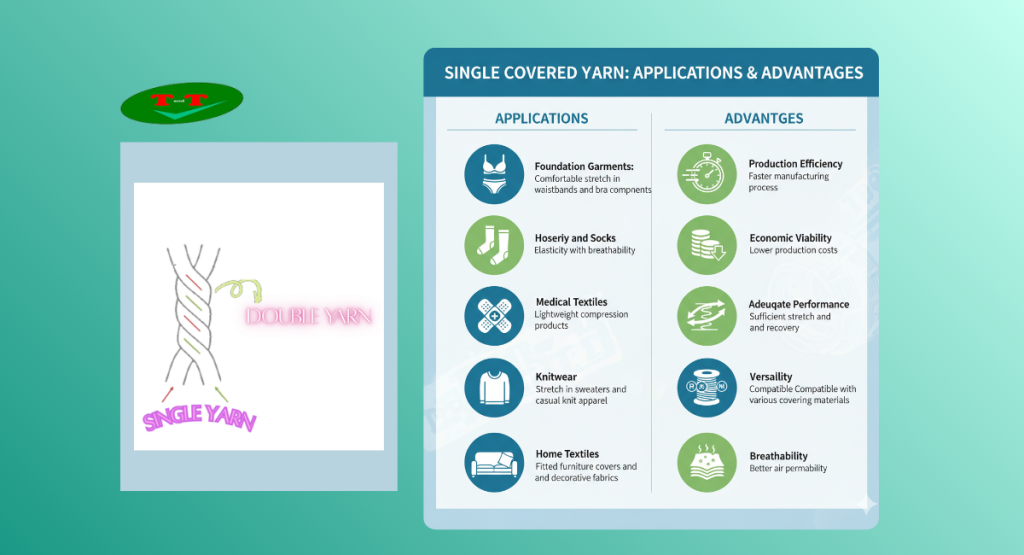

Applications

Single covered yarn finds extensive use across multiple textile sectors:

- Foundation Garments: Providing comfortable stretch in waistbands and bra components

- Hosiery and Socks: Delivering necessary elasticity with breathability

- Medical Textiles: Used in lightweight compression products and surgical hosiery

- Knitwear: Incorporating stretch in sweaters and casual knit apparel

- Home Textiles: Adding functional stretch to fitted furniture covers and decorative fabrics

Advantages

The strategic benefits of single covered yarn make it a popular choice for many applications:

- Production Efficiency: Faster manufacturing process compared to double covering

- Economic Viability: Lower production costs translate to better pricing

- Adequate Performance: Sufficient stretch and recovery for many applications

- Versatility: Compatible with various covering materials including cotton, polyester, and nylon

- Breathability: Better air permeability than fully encapsulated elastomeric yarns

Comparison: Single Covered Yarn vs Double Covered Yarn

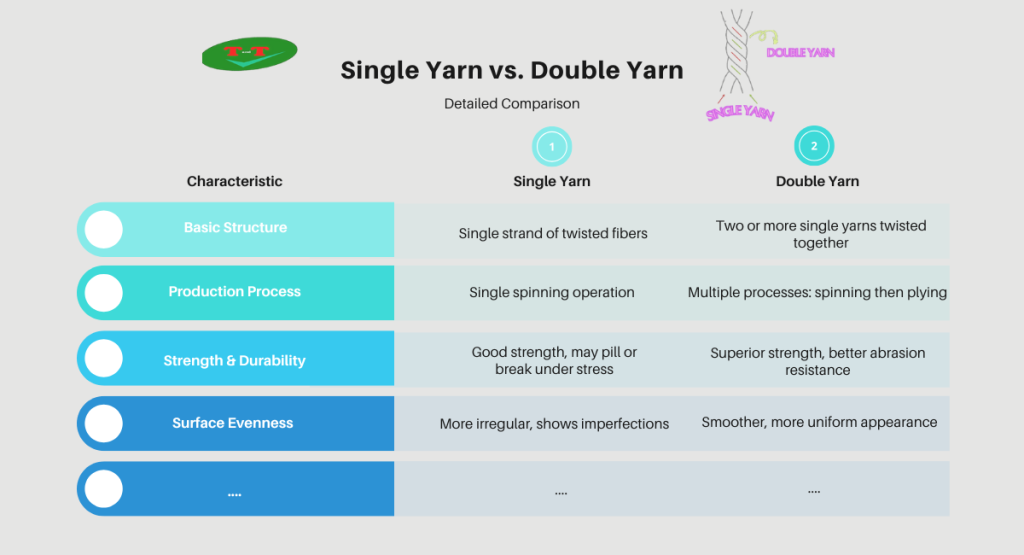

The fundamental distinction lies in their construction: single yarn consists of a single twisted strand of fibers, while double yarn comprises two or more single yarns twisted together. This structural difference creates a clear divergence in performance characteristics and ideal applications.

| Characteristic | Single Yarn | Double Yarn |

| Basic Structure | Single strand of twisted fibers | Two or more single yarns twisted together |

| Production Process | Single spinning operation | Multiple processes: spinning then plying |

| Strength & Durability | Good strength, may pill or break under stress | Superior strength, better abrasion resistance |

| Surface Evenness | More irregular, shows imperfections | Smoother, more uniform appearance |

| Cost Efficiency | More economical, faster production | Higher cost due to additional processing |

| Weight & Thickness | Lighter weight for same yarn count | Heavier and thicker construction |

| Common Applications | Basic fabrics, filling yarns, pile fabrics | Knitting yarns, weaving warp yarns, premium fabrics |

| Typical Yarn Count Range | Wider range, from very fine to coarse | Generally medium to coarse counts |

Common Types of Single Covered Yarn

Single covered yarn variations are categorized by their covering material, with each type selected for specific performance characteristics. The choice of covering fiber significantly influences the yarn’s properties, making certain fibers particularly suitable for single covering applications where their inherent advantages can be fully utilized.

Nylon-Spandex Single Covered Yarn

Nylon is a premier choice for single covering due to its high strength, excellent abrasion resistance, and smooth surface, which aligns perfectly with the goal of creating a crisp, durable yarn. The high strength of the nylon sheath effectively protects the spandex core during the weaving and knitting processes, reducing breakage. This combination results in a yarn with a smooth hand feel and a fabric style that is characteristically smooth and crisp. Its excellent dye affinity ensures vibrant colors.

This yarn is ideal for high-elasticity knitted fabrics, swimwear, ski suits, and high-quality warp-knitted and jacquard fabrics where durability and a defined structure are required.

Polyester-Spandex Single Covered Yarn

Polyester is favored for its exceptional dimensional stability, high strength, and excellent resistance to UV light and chemicals. In the single covering process, the hardness of the polyester filament contributes to the yarn’s overall resilience and crispness. The resulting yarn is robust and maintains its shape well, making it suitable for fabrics that require a slightly stiffer drape and high wear resistance.

It is widely used in sportswear (like sports tights), industrial textiles, sports equipment, and suits or T-shirts that benefit from a more structured, durable fabric.

Cotton-Spandex Single Covered Yarn

Cotton is chosen for single covering to create yarns with a natural, soft hand feel and high breathability. The process combines the comfort of cotton with the functional stretch of spandex. However, as cotton is a staple fiber with lower strength compared to filament nylon or polyester, achieving an even coverage requires careful control of the twist (TPM) to prevent the spandex core from being exposed during high-stretch applications.

This yarn is ideal for everyday comfort wear, premium t-shirts, casual knitwear, lightweight compression garments for sensitive skin, and intimate apparel where natural fiber feel is a priority.

Conclusion

Single covered yarn stands as an essential component in modern textile manufacturing, offering a practical balance between performance, cost, and versatility. Its straightforward construction provides reliable stretch characteristics while maintaining manufacturing efficiency that benefits both producers and end-users. Understanding the different types and their specific advantages enables manufacturers to select the most appropriate single covered yarn for their particular application needs, ensuring optimal performance in the final product.

Whether for fashion, technical textiles, or specialized applications, single covered yarn continues to be a go-to solution for incorporating comfortable, functional stretch into diverse fabric constructions.

Ready to explore single covered yarn options for your next project? Contact our technical team today for expert guidance, sample requests, and customized solutions tailored to your specific requirements.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread