Spandex fabric, the engineered backbone of modern comfort and performance apparel, has revolutionized the textile industry. For manufacturers, navigating the world of spandex—from its diverse properties and global supply chain to cost and compliance—is critical for creating competitive products.

This definitive guide provides a deep dive into spandex fabric, offering practical insights for sourcing, certification, and utilization to empower strategic decision-making in your production line.

What Is Spandex Fabric?

Spandex, also known internationally as elastane or by the brand name Lycra®, is a synthetic fiber renowned for its exceptional elasticity. Unlike a fabric in itself, it is a polyurethane-based filament that is almost always blended with other fibers—such as cotton, polyester, or nylon—in small percentages (typically 2%-20%). This integration transforms rigid materials into flexible, body-hugging fabrics that can stretch over 500% and recover to their original shape. The core value of spandex fabric lies in this unique ability to provide freedom of movement, superior comfort, and enhanced fit without compromising the inherent characteristics of the primary fiber.

Key Properties of Spandex

The dominance of spandex in apparel is due to a combination of unparalleled properties:

- Exceptional Elasticity and Recovery: This is its defining characteristic. Spandex can stretch repeatedly without breaking and return to its original length, preventing garments from becoming baggy.

- Strength and Durability: Despite its delicate appearance, spandex is stronger than rubber and resistant to degradation from body oils, sweat, and lotions.

- Lightweight and Smooth: It adds minimal weight and bulk, allowing for sleek, form-fitting designs.

- Versatility in Blending: It can be seamlessly integrated with almost any other fiber to create fabrics with tailored performance.

Applications of Spandex

These unique mechanical properties are precisely what make spandex an indispensable ingredient across diverse apparel categories. The ability to provide controlled stretch and recovery is not merely a feature but a functional requirement that directly translates into enhanced performance, comfort, and durability in the final product.

Activewear & Sportswear

Spandex is typically blended with nylon or polyester in percentages from 10% to 25%. This creates fabrics with bi-directional or four-way stretch, allowing the garment to move in all directions with the body. It provides dynamic support, unrestricted movement, and muscle stabilization during physical activity.

Specific Examples:

- Yoga Leggings: The high spandex content offers a “second-skin” feel and exceptional recovery, ensuring the leggings remain opaque and do not bag at the knees during deep stretches.

- Compression Tights/Cycling Shorts: It provides graduated compression to support blood flow, reduce muscle fatigue, and minimize vibration. The snug fit also reduces air resistance.

- Sports Bras: Spandex is critical for the under-band and straps, offering stretch for easy wearability while its strong recovery provides the necessary support to minimize breast movement during high-impact activities.

Intimate Apparel & Shapewear

Spandex is used in lace, power mesh, and satin weaves, often in blends. In shapewear, it is combined with rigid fibers to create zones of varying compression. The main purpose is to deliver secure fit, adaptive comfort, and targeted contouring.

Specific Examples:

- Bras & Underwear: It provides the essential elasticity in waistbands, leg openings, and bra bands for a secure fit that doesn’t dig in. It also allows the fabric to adapt to the body’s shape throughout the day.

- Shapewear/Bodysuits: Spandex enables the creation of “power net” fabrics that offer firm control. Its high recovery is crucial to prevent the garment from permanently stretching out, ensuring it maintains its sculpting effect over time.

Swimwear

Spandex is blended with chlorine-resistant nylon or solution-dyed polyester. The fabric is engineered for high recovery even when wet to ensure a snug, secure fit that resists water absorption and degradation from elements.

Specific Examples:

- Competition Swimsuits: The spandex blend provides muscle compression and reduces drag through an ultra-snug, hydrodynamic fit.

- Recreational Bikinis & One-Pieces: It prevents the suit from sagging, bagging, or becoming transparent when wet, ensuring the garment maintains its shape and coverage.

Fashion Apparel

Small percentages (2-5%) are blended with natural or synthetic fibers to add give without compromising the fabric’s primary hand feel. The result is to add “comfort stretch,” improve fit, and enhance the durability of garments.

Specific Examples:

- Stretch Denim: Just 1-3% spandex eliminates the rigid feel of traditional denim, allowing jeans to move with the body, fit more closely, and resist bagging at the knees.

- T-Shirts & Knit Tops: It allows for a more fitted silhouette that recovers its shape after stretching, reducing wrinkles and preventing the neckline from becoming loose.

- Tailored Trousers & Blazers: In wovens, a small amount of spandex allows for ease of movement without creating wrinkles, making garments more comfortable for sitting and moving while maintaining a sharp appearance.

Other Applications

The utility of spandex extends far beyond traditional apparel into technical and medical fields.

Specific Examples:

- Medical Textiles:

- Compression Garments: Used for burn recovery, lymphedema management, and post-surgical support to apply consistent, therapeutic pressure.

- Sports Medicine: Elastic bandages, kinesiology tape, and supports that stabilize joints without restricting movement.

- Hosiery: Socks and stockings use spandex to maintain their position without garters and to provide light compression for improved circulation.

- Home Furnishings: Fitted bed sheets and furniture covers use spandex to create an elasticated edge that stays securely in place.

- Automotive Upholstery: Spandex blends in seat covers allow the fabric to conform comfortably to the seat’s contours and withstand repeated entry and exit.

Comparison of Different Types of Spandex

While “spandex” is a general term, its performance can vary based on its manufacturing and blending. The key differentiation often lies in the resulting fabric rather than the spandex filament alone.

| Type of Fabric | Key Characteristics | Ideal Applications |

| Nylon-Spandex | Very soft, smooth hand feel, high durability, excellent abrasion resistance. Dyes to vibrant colors. | Swimwear, activewear, leggings, intimate apparel. |

| Polyester-Spandex | High strength, excellent UV and chlorine resistance, good colorfastness, quick-drying. | Performance sportswear, swimwear, outdoor uniforms, sublimation printing. |

| Cotton-Spandex | Natural, soft hand feel, breathable, absorbent, but slower drying than synthetics. | T-shirts, casual wear, leggings, comfortable intimate apparel. |

| Wool-Spandex | Retains wool’s natural warmth and breathability while adding stretch and reducing shrinkage. | Performance base layers, stretch suiting, high-end knitwear. |

Spandex Fabric in International Trade

The global spandex fabric market is vast and complex, with a supply chain heavily concentrated in Asia. China is the world’s largest producer and consumer, accounting for a significant majority of global capacity, followed by other key players like South Korea, Taiwan, and Vietnam. This concentration offers competitive pricing and high-volume capacity but requires diligent supplier vetting. The market is characterized by constant innovation, with a growing segment dedicated to sustainable and recycled spandex options to meet evolving consumer demands.

International Certifications for Spandex

In the complex global textile supply chain, international certifications serve as critical risk management tools, providing verifiable proof of quality, safety, and sustainable practices. They are not just badges for marketing but essential credentials that ensure regulatory compliance, protect brand reputation, and build trust with increasingly conscious consumers and retailers.

- OEKO-TEX® Standard 100: This is the most critical certification for apparel. It tests for the presence of harmful substances, ensuring the fabric is safe for human skin contact. For brands selling in Europe and North America, this is often a non-negotiable requirement.

- Global Recycled Standard (GRS): Certifies the recycled content in the fabric. As demand for circular economy products grows, GRS-certified spandex blends (often using recycled polyester or nylon) provide a marketable advantage.

- bluesign®: A comprehensive system that approves chemicals, processes, and materials for sustainable textile production. A bluesign® certification indicates the fabric was made with the lowest possible environmental impact.

- ISO Quality Management (e.g., ISO 9001): While not a product-specific certificate like OEKO-TEX®, an ISO 9001 certification indicates that the supplier has a robust Quality Management System (QMS) in place. This ensures consistent production processes, reliable product quality, and continuous improvement, making it a key indicator of a manufacturer’s overall reliability and operational excellence.

Why manufacturers need these certifications: They are not just badges; they are risk management tools. Certifications ensure regulatory compliance for international exports, build brand trust and credibility with conscious consumers, and provide a verifiable chain of custody for sustainable claims, future-proofing your supply chain.

Pricing of Spandex Fabric

The pricing of spandex fabric is highly dynamic, with a base range primarily determined by the fiber blend (e.g., cotton-spandex vs. nylon-spandex), denier (fiber thickness), elasticity level (spandex percentage), specialized finishing (e.g., moisture-wicking, UV protection), and order volume. Beyond these product-specific factors, several macro and commercial drivers significantly impact cost.

- Raw Material Costs: The price of petrochemicals (PTMEG and MDI) directly impacts spandex filament cost.

- Blend Composition: A 95% Cotton / 5% Spandex jersey will be priced differently than an 85% Nylon / 15% Spandex tricot. The type and quality of the companion fiber are major cost drivers.

- Fabric Construction: Complex weaves or knits (e.g., seamless, jacquard) command a higher price than basic jerseys.

- Certifications and Finishes: Specialty finishes (moisture-wicking, anti-odor) and certifications add cost but also value.

- Trade Policies: Import/export tariffs and trade agreements between countries can add substantial cost layers.

- MOQ and Negotiation: Larger order volumes typically command lower per-unit prices.

The market is witnessing a trend of price polarization. While standard spandex blends remain competitively priced due to high-volume production in Asia, there is a growing premium for specialized, high-performance, and eco-friendly variants (e.g., recycled content, bio-based spandex).

Reference Market Prices

| Fabric Type | Key Characteristics | Price Range (FOB Asia, USD/Meter) |

| Basic Cotton-Spandex Jersey | (e.g., 95/5 blend), for casual wear | $2.50 – $4.00 |

| Nylon-Spandex Tricot | Soft, durable, for activewear & swimwear | $3.50 – $6.00 |

| Performance Polyester-Spandex | Quick-dry, UV resistant, for sportswear | $4.00 – $7.00+ |

| Recycled PET-Spandex Blend | With GRS certification, sustainable focus | +15% – 30% vs. standard polyester |

Note: Prices are indicative and subject to rapid change based on the factors listed above.

Key Factors to Consider When Purchasing Spandex Fabric

- Define Your Performance Needs: Is it for high-intensity compression or casual comfort? This determines the spandex percentage and base fiber.

- Supplier Reliability and Compliance: Audit potential suppliers for consistent quality, on-time delivery, and possession of relevant certifications.

- Minimum Order Quantity (MOQ): Asian mills often have high MOQs (1,000 meters+). Factor this into your production and inventory planning.

- Lead Times and Logistics: Account for production and shipping times, especially for seasonal collections. Ocean freight from Asia can take 4-6 weeks.

- Request and Test Swatches: Always evaluate the fabric’s hand feel, weight, stretch, recovery, and color in person before placing a bulk order.

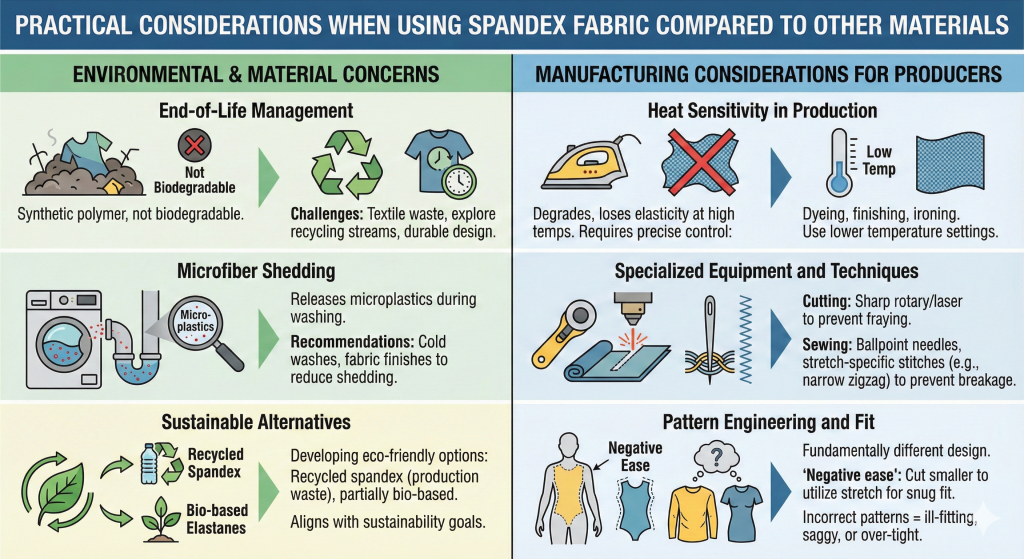

Practical Considerations When Using Spandex Fabric Compared to Other Materials

Designing and manufacturing with Spandex presents unique challenges that differ fundamentally from working with stable woven fabrics or standard natural fibers. The material’s specific properties require precise technical adjustments, from using ballpoint needles and specialized rotary cutters to engineering patterns with ‘negative ease’ for the perfect fit. Furthermore, producers must exercise strict control over processing temperatures to preserve elasticity.

Environmental & Material Concerns

- End-of-Life Management: As a synthetic polymer, spandex is not biodegradable. This presents a challenge for textile waste, necessitating exploration of recycling streams or durable product design to extend lifespan.

- Microfiber Shedding: Like other synthetics, spandex blends can release microplastics during washing. Manufacturers should consider recommending cold washes and exploring fabric finishes that reduce shedding.

- Sustainable Alternatives: The industry is developing more eco-friendly options, including recycled spandex (often from production waste) and partially bio-based elastanes. Sourcing these materials can align with corporate sustainability goals and appeal to a growing market segment.

Manufacturing Considerations for Producers:

- Heat Sensitivity in Production: Spandex can degrade and lose elasticity at high temperatures. This requires precise control during dyeing, finishing, and ironing. Factories must train operators on using lower temperature settings to preserve the fabric’s core properties.

- Specialized Equipment and Techniques: Cutting spandex requires sharp rotary cutters or laser cutting to prevent fraying and distortion. Sewing demands ballpoint needles to slip between yarns rather than pierce them, and using stretch-specific stitches (like a narrow zigzag) is crucial to prevent seam breakage.

- Pattern Engineering and Fit: Designing for spandex is fundamentally different. Patterns must account for the fabric’s “negative ease,” meaning the garment is cut smaller than the body to utilize the stretch for a snug fit. Failure to engineer patterns correctly results in ill-fitting, saggy, or over-tight garments.

Conclusion

Spandex fabric is no longer a niche material but a fundamental component of modern apparel manufacturing. Its unique properties enable the comfort, performance, and fit that today’s consumers demand. A strategic approach—combining a deep understanding of its technical properties with savvy global sourcing and practical production knowledge—is essential for leveraging spandex to create superior, market-leading products.

Navigating the complexities of spandex yarn sourcing can be daunting. Let us simplify it for you. Contact our material experts today to request complimentary swatches, get detailed technical data sheets, and receive a competitive quotation tailored to your specific project needs.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread