In the intricate world of synthetic textiles, a material’s final quality and performance are often determined at the very beginning of its production journey. Partially Oriented Yarn (POY) is the essential, semi-finished foundation upon which a vast range of modern fabrics are built.

This guide provides a clear, technical overview of what POY is, its defining characteristics, its transformative role across multiple industries, and the growing importance of its sustainable variants, offering crucial insights for manufacturers, brands, and textile professionals.

What is POY Yarn? Definition and Industry Position

Partially Oriented Yarn (POY) is a specific form of continuous polyester filament that has undergone an initial, but incomplete, drawing process immediately after the polymer is melt-spun. Also referred to as Polyester Pre-Oriented Yarn, it is the primary, intermediate state of polyester before it is further processed into its final form.

Its core significance lies in its role as a versatile precursor. POY is not typically used as an end-product fabric itself. Instead, it serves as the critical raw material for manufacturing other yarns, most notably Draw Textured Yarn (DTY), which gives fabrics stretch, bulk, and a soft handfeel. This “semi-finished” condition makes POY exceptionally cost-effective and flexible, allowing manufacturers to produce a wide array of final yarns with different properties from a single, standardized intermediate product.

Technical Specifications and Competitive Advantages of POY

The unique “partially oriented” state of POY grants it a distinct balance of physical properties that are advantageous for downstream processing.

Physical and Mechanical Properties

POY exhibits a moderate tenacity (strength) and a moderate-to-high elongation (stretch) compared to fully drawn yarns. This is because its polymer chains are only partially aligned during the high-speed spinning process, leaving significant potential for further drawing and texturing. It possesses good elasticity and thermoplasticity, meaning it can be reshaped with heat, which is essential for the texturing process.

It is important to note that POY generally has lower tenacity and less uniformity than a Fully Drawn Yarn (FDY), which undergoes a complete drawing process to maximize strength and orientation.

Benefits for Textile End-Products

When transformed into final fabrics, POY-derived materials offer several key performance benefits:

- Durability and Wrinkle Resistance: Fabrics maintain a neat appearance with high crease recovery and resistance to wrinkling.

- Color Fastness and Print Retention: They demonstrate excellent dye uptake and color stability, ensuring prints and colors last longer.

- Abrasion Resistance: POY-based fabrics show better resistance to wear and tear compared to some other fiber types.

- Customizability: POY is available in a wide range of deniers (thicknesses, e.g., from 30D to 600D) and filament counts, allowing precise specification for different applications, from fine lingerie to heavy upholstery.

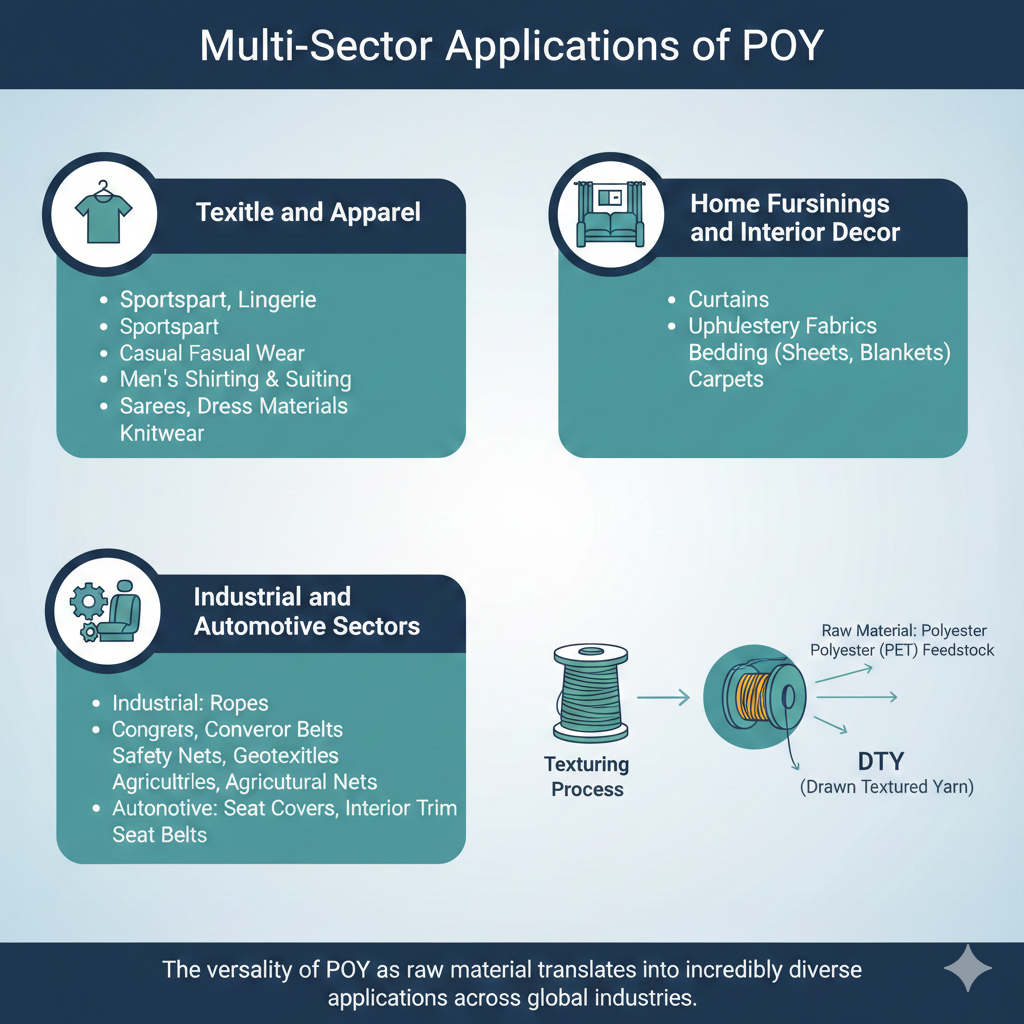

Multi-Sector Applications of POY

The versatility of POY as a raw material translates into incredibly diverse applications across global industries.

- Textile and Apparel: This is the primary application sector. POY is the fundamental feedstock for producing textured yarns (DTY), which are then used to create fabrics for sportswear, lingerie, casual wear, and fashion items. It is particularly favored in men’s shirting and suiting fabrics due to its excellent drape, wrinkle resistance, and durability. POY is also widely used in the production of sarees, dress materials, and various knitwear.

- Home Furnishings and Interior Decor: POY‘s durability and adaptability make it ideal for home textiles. It is extensively used in manufacturing curtains, upholstery fabrics, bedding (sheets, blankets), and carpets. In upholstery, for example, POY-derived yarns contribute to fabric strength, stain resistance, and ease of maintenance.

- Industrial and Automotive Sectors: In industrial settings, the reliability and strength of POY make it indispensable for products like ropes, conveyor belts, safety nets, geotextiles, and agricultural nets. The automotive industry utilizes POY in seat covers, interior trim fabrics, and seat belts, where resistance to abrasion, UV light, and wear is paramount for safety and longevity.

The Production Process: From Polymer to POY

POY is manufactured through a continuous, high-speed melt spinning process. The production can be summarized in key stages:

- Polymerization & Melting: Raw materials—primarily Purified Terephthalic Acid (PTA) and Monoethylene Glycol (MEG)—are processed into polyester polymer, which is then melted.

- Extrusion: The molten polymer is forced through a spinneret, a metal plate with tiny holes, to form continuous liquid filaments.

- Quenching & Solidification: The filaments are rapidly cooled (quenched) by an air stream, solidifying them into solid fibers.

- Partial Drawing/Orientation: The filaments are drawn (stretched) at high speed. This step is carefully controlled to only partially align the polymer molecules, giving POY its name and its unique potential for further processing. The yarn is then wound onto bobbins.

Sustainability and Recycled POY

- The Rise of Recycled POY (rPOY): A significant and growing trend is the production of Recycled POY. This sustainable alternative is made from post-consumer waste, such as used PET bottles, or post-industrial polyester waste. The use of rPOY significantly reduces reliance on virgin petrochemical resources and lowers the carbon footprint of the final textile product.

- Contribution to the Circular Economy: Recycled POY is a cornerstone of the circular economy in textiles. By giving plastic waste a new life as high-quality fiber, it addresses critical environmental concerns about resource depletion and pollution. Leading brands are increasingly committing to using recycled polyester to meet consumer demand for eco-friendly products and comply with stricter global regulations. The industry is also focusing on improving overall sustainability through measures like enhancing energy efficiency in production and reducing water and chemical usage.

Conclusion

Partially Oriented Yarn (POY) is far more than just an intermediate product; it is the strategic starting point that defines the efficiency, performance, and sustainability profile of a vast portion of the global textile industry. Its unique combination of versatility, cost-effectiveness, and performance has solidified its role as an indispensable material. As the industry pivots decisively towards circularity, innovations in Recycled POY are ensuring this foundational fiber remains relevant and responsible for the future of fashion, home furnishings, and industrial textiles.

At Tani Thread, we specialize in manufacturing covered yarn tailored for the U.S. market, using carefully selected POY to ensure consistent elasticity, durability, and performance. If you are sourcing reliable covered yarn for apparel, hosiery, or technical textile applications, we welcome you to connect with Tani Thread to discuss your requirements and supply needs.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread

Frequently Asked Questions (FAQs)

What is POY yarn?

POY stands for Partially Oriented Yarn. It is a semi-finished, continuous filament polyester yarn produced through a high-speed melt spinning process where the polymer is only partially stretched (drawn). This intermediate state givesPOY its unique potential for further texturing and processing into final yarn products like DTY.

How is POY different from FDY?

The core difference lies in the degree of molecular orientation. FDY (Fully Drawn Yarn) undergoes a complete drawing process, resulting in higher tensile strength, greater dimensional stability, and a finished state ready for direct use in weaving or knitting. POY, being only partially drawn, has lower tenacity but superior elasticity and is specifically designed as a precursor for further mechanical processing like draw texturing.

What are the main applications of POY yarn?

The primary application of POY is as the raw material for producing textured yarns, most notably Draw Textured Yarn (DTY). POY-derived yarns are fundamental to fabrics in apparel (sportswear, lingerie, suiting), home furnishings (curtains, upholstery), and industrial textiles (ropes, automotive interiors) that require elasticity, bulk, and a soft handfeel.

Is POY cost-effective?

Yes. POY is generally considered a more cost-effective option compared to FDY and other finished yarns. Its production is streamlined for high output, and its semi-finished nature allows manufacturers to centralize production and then customize it in subsequent texturing processes, leading to economies of scale and flexible inventory management.

What are the raw materials for producing POY?

POY is primarily produced from polyester polymers. The main raw materials are Purified Terephthalic Acid (PTA) and Monoethylene Glycol (MEG), which are polymerized to create the polyester melt. Alternatively, ready-made polyester chips can be re-melted and spun into POY filaments.