The textile industry relies heavily on filament yarns, which consist of fibers of continuous or unlimited length, contrasting with staple spun yarns made from small length fibers. While these concepts can apply to any synthetic fiber yarn, the terms Partially Oriented Yarn (POY), Fully Drawn Yarn (FDY), and Drawn and Textured Yarn (DTY) are most commonly used when discussing polyester filament yarns.

These terms define the yarn based on the extent of drawing (stretching) and subsequent texturization it undergoes after the initial spinning process. Understanding the fundamental differences in orientation and structure is crucial because these variations dictate the final properties, stability, and suitable applications of the yarn.

The orientation refers to how the crystalline domains, or regions where large polymer chains are ordered, align along the axis or length of the yarn. The degree of this alignment, which is achieved through post-spinning drawing, is what separates POY, FDY, and DTY.

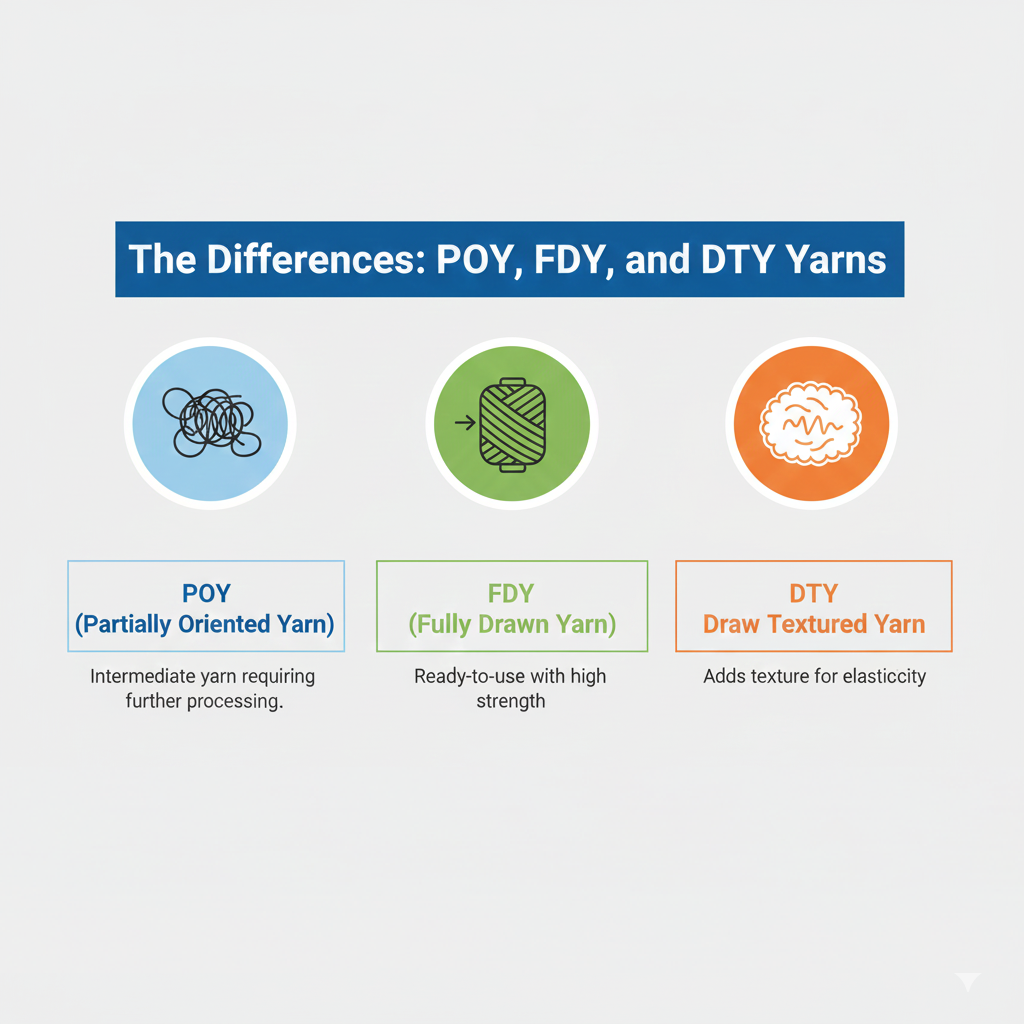

Comparative Summary of POY, FDY, and DTY Yarns

POY, FDY, and DTY are types of polyester yarns differentiated by their production processes and properties. POY (Partially Oriented Yarn) is an intermediate yarn requiring further processing, while FDY (Fully Drawn Yarn) is ready-to-use with high strength, and DTY (Draw Textured Yarn) adds texture for elasticity.

| Feature | Partially Oriented Yarn (POY) | Fully Drawn Yarn (FDY) | Drawn and Textured Yarn (DTY) |

| Drawing/Orientation | Partially oriented/stretched; Incompletely stretched. | Fully drawn; Significantly oriented. | Fully drawn (or stretched) and Textured. |

| Production Process | High-speed spinning; Cold drawn yarn. | High-speed spinning with stable intermediate drawing; Hot drawn yarn. | Simultaneous twisting and drawing, typically using POY as feedstock. |

| Crystallinity | Low, typically 2% to 5%. | High, typically 35% to 40%. | Result of drawing/texturing process; Increased bulkiness. |

| Remaining Elongation | High (80% or more left). | Low (40% or less left). | Offers more stretch and flexibility than FDY. |

| Shrinkage | Very High (50% to 70%). | Very Low (6% to 12%). | Depends on texturing, generally stable post-processing. |

| Texture/Feel | Pre-oriented, precursor yarn; Softer feel. | Flat yarn; High strength, smoothness. | Soft crimp, fluffy appearance, bulkiness. |

| Stability | Stable for short durations (storage 6-8 months). | Stable structure throughout life span. | Durable structure with high bulk retention. |

| Primary Use | Converting into DTY or used in weaving/knitting. | High-strength non-textured fabrics, sewing threads, curtains. | Outer/inner garments, upholstery, skin-clinging garments requiring elasticity. |

Understanding the Core Concepts: Orientation and Drawing

Synthetic filament yarns are made from long polymer chains that contain ordered crystalline regions interspersed with less ordered amorphous regions. When the polymer is extruded through the spinneret to form a filament (known as an as-spun filament), the initial orientation of these crystalline domains along the fiber axis is usually poor, leading to insufficient strength.

To achieve the necessary strength and stability, a critical post-spinning operation called drawing is performed, which involves stretching the filaments. Drawing significantly improves the alignment, or orientation, of these crystalline domains along the yarn axis.

The extent of this drawing process is what defines the three main yarn types:

1. Partial orientation (resulting from partial stretching) defines Partially Oriented Yarn (POY),. POY is considered a cold drawn yarn.

2. Full orientation (resulting from significant stretching) defines Fully Drawn Yarn (FDY),. FDY is typically produced via hot drawing, which further stabilizes the polymeric chains.

In essence, whether a yarn is classified as POY, FDY, or DTY depends entirely on the degree of structural orientation and whether subsequent texturization has been applied.

Partially Oriented Yarn (POY): The Foundation

Partially oriented yarn (POY) represents the first form of yarn created when a polymer is converted into a continuous filament.

Definition and Production

In POY, the crystalline domains of the polymer are only partially oriented along the yarn or filament axis. The orientation degree falls between completely unoriented filaments and fully drawn filaments, resulting from high-speed spinning. A drawing effect may occur as the molten polymer, solidified by quenched or cold air after extrusion from the spinneret, passes over take-up rollers before being wound onto a bobbin.

While POY is not fully stretched, this partial orientation does impart sufficient strength, enabling the yarn to withstand the mechanical stresses encountered during subsequent downstream processing required to convert it into fabric. POY is known as a pre-oriented yarn.

Key Properties

POY is characterized by properties that make it highly suitable for further modification, particularly texturing:

- Low Crystallinity: The degree of crystallinity in POY is quite low, ranging only up to 5%. In fact, it is specifically cited as having approximately 2% to 5% crystallinity.

- High Elongation: Because POY is not fully stretched, it retains a significant capacity for further elongation. The remaining elongation capacity within its structure must be above 80%.

- High Shrinkage: Due to its low crystallinity and high amorphous region, POY exhibits very high shrinkage. This shrinkage can range from 50% to 70%.

- Stability: POY is stable only for short durations and can typically be stored for 6 to 8 months.

- Luster and Color: POY is available in semi-dull and bright lusters. Semi-dull luster is often achieved by mixing titania into the polymer melt. It is available in raw white and dope-dyed colors. Dope-dyed POY is advantageous because it eliminates the need for fabric dyeing, making it more eco-friendly.

Primary Applications and End Use

POY itself cannot be used directly for textile processing due to its incomplete stretching and unstable nature. Its main purpose is to serve as the feed material for texturizing units that convert it into texturized yarn, most notably drawn textured yarn (DTY).

When used in final products, POY is known for providing desirable textile attributes such as a softer feel, better drape, higher recovery, wrinkle resistance, and long-lasting prints and colors. It is used in various woven and knitted fabrics, including materials for ladies’ and gents’ clothing, home textiles, sportswear, shirts, suits, and sarees.

Fully Drawn Yarn (FDY): Strength and Stability

Fully Drawn Yarn (FDY), also referred to as polyester filament yarn (PFY/PSF) or spin drawn yarn (SDY), is characterized by a high degree of orientation achieved through intensive drawing.

Definition and Production

In FDY, the drawing or stretching process is executed to a significant extent, resulting in the crystalline domains in the polymer being highly oriented along the yarn axis. FDY is defined as a full stretch yarn, and the fiber has been fully stretched.

FDY is typically produced at higher speeds than POY, incorporating stable intermediate drawing integrated into the processes of stretching, orientation, and crystallization. Unlike POY, which is cold drawn, FDY is produced via hot drawing. This full drawing makes FDY yarn significantly stronger than POY yarn.

Key Properties

FDY’s full orientation translates directly into high stability and tensile strength:

- High Crystallinity: Due to the high degree of orientation of polymeric chains, the crystallinity of FDY is high, reaching up to 40%. Sources specify crystallinity is around 35% to 40%.

- Low Elongation: Since FDY is fully oriented, the possibility of further elongation is low, generally about 40% or less. This characteristic makes FDY more structurally stable than POY.

- Low Shrinkage: High crystallinity means the shrinkage in FDY is very low when compared with POY. Shrinkage is usually up to 12%, or specifically in the range of 6% to 12%.

- Stability: FDY possesses a stable structure and remains stable throughout its lifespan.

- Texture: FDY is primarily used as a flat yarn to manufacture non-textured fabrics. It is valued for its high tensile strength and smoothness.

- Luster and Cross-Section: FDY is available in semi-dull and bright lusters. While most filament cross sections are circular, FDY can also be trilobal or triangular, which results in a brighter luster, often utilized in making curtains.

Primary Applications and End Use

Because the fiber in FDY has been fully stretched, it can be directly used for textile processing. FDY is highly compatible and can be easily knitted or woven with other yarns to produce a variety of fabrics.

FDY is primarily used in making high-strength textiles and fabrics. Specific applications include:

- Home Textiles and Furnishings: Curtains, home furnishing, and Rachel blankets.

- Technical Textiles: Automotive and other technical textiles.

- Apparel: Sportswear, high-end undergarments, fashion fabrics, and denim.

- Non-Textured Fabrics: Due to its flat structure, it is ideal for non-textured fabrics such as hospital clothes, pads, and surgical sets.

- Other Uses: Sewing threads, embroidery threads, Chanel yarns, crepe, and lace fabrics.

Drawn and Textured Yarn (DTY): Bulk and Flexibility

Drawing is not the only post-spinning operation; texturization of the filament surface can also be performed after spinning.

Definition and Production (The Texturing Process)

Drawn and Textured Yarn (DTY) is yarn that has been both drawn (stretched) and textured. Texturization involves giving the otherwise flat fiber or filament surface a special effect, such as introducing crimp or twist into the structure.

DTY production typically involves using POY as the feedstock, though FDY can also be texturized (FDY is usually used as flat yarn). The manufacturing process involves simultaneous twisting and drawing using a high-pitched POY texturing machine. This process creates continuous filament yarns with permanent distortions, which may take the form of coils, loops, crinkles, or crimps. Texturization disperses, curls, and entangles the filaments, resulting in a fluffy appearance.

Key Properties

The defining feature of DTY is its enhanced structure and texture:

- Bulkiness: Texturization dramatically increases the bulkiness of the yarn. The introduction of crimps, twists, loops, or interlaces contributes to this bulk.

- Elasticity and Strength: The processes of stretching, twisting, and texturing enhance both the elasticity and the strength of the yarn. DTY offers more stretch and flexibility compared to FDY.

- Hand Feel: DTY is known for being softer with a crimp texture, providing a soft hand feel. Its fluffy appearance gives it properties akin to both natural and synthetic fibers.

- Superior Properties: DTY possesses superior textile and dyeing properties. It is also known for its high bulk, durability, and retention.

Primary Applications and End Use

DTY is suitable for applications where good draping and elasticity are required.

Its high bulk and soft feel make it ideal for:

- Garments: Outer and inner garments, including skin-clinging garments.

- Furnishings: Home furnishings, upholstery, and seat covers.

- General Textiles: Weaving and knitting applications, bags, and high-end sportswear.

DTY can be manufactured with different combinations of intermingle points and can be twisted to high counts like 1500 TPM or 4000 TPM to suit specific technical requirements.

Conclusion

In summary, the classification of POY, FDY, and DTY describes the progression of a synthetic filament yarn from its initial state to its final textile form. POY is the partially oriented yarn, serving mainly as an intermediate product. FDY is the fully drawn or oriented yarn, characterized by high stability, strength, and low shrinkage. Finally, DTY is the drawn, stretched, and textured yarn, prized for its bulkiness, elasticity, and soft feel. The extent of drawing, whether partial, full, or followed by texturization, fundamentally determines the yarn’s physical properties and its appropriate end use in the textile market.

Understanding POY, FDY, and DTY is the first step—covered yarn is where these yarns create real value. At Tani Thread, POY is a key raw material in our production of covered yarn, engineered to meet the performance and consistency requirements of the U.S. market.

As a Vietnam-based yarn manufacturer specializing in covered yarn, we supply reliable solutions for apparel, hosiery, and elastic textile applications. If you are sourcing covered yarn and need a dependable manufacturing partner, contact Tani Thread to discuss your order requirements.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread