Covered spandex yarn is a versatile and essential component in the textile industry, combining the elasticity of spandex with the strength and durability of various covering fibers. This innovative material has revolutionized the production of stretchable fabrics, finding applications in diverse sectors from activewear to medical textiles. In this comprehensive guide, we’ll explore the intricacies of covered spandex yarn types, its variations, applications, and comparisons to other materials.

Covered Spandex Yarn

Covered spandex yarn is a composite yarn that consists of a spandex core wrapped with one or more layers of covering fibers. This unique construction offers the best of both worlds: the exceptional stretch and recovery properties of spandex combined with the desirable characteristics of the covering material.

Manufacturing Process

The production of covered spandex yarn involves a sophisticated process where a spandex filament is fed through a specialized machine. As the spandex core moves through the machine, it is wrapped with a covering fiber, typically polyester, nylon, or cotton. This covering process can be single or double, resulting in different yarn characteristics.

Applications in Textiles

Covered spandex yarn finds extensive use in various textile applications due to its remarkable properties. It is commonly used in:

- Activewear and sportswear

- Lingerie and underwear

- Swimwear

- Compression garments

- Medical textiles

The incorporation of covered spandex yarn in these products enhances their stretch, comfort, and shape retention capabilities.

Benefits and Advantages

The use of covered spandex yarn offers numerous benefits to both manufacturers and consumers:

- Improved fabric durability

- Enhanced comfort and fit

- Better shape retention

- Increased garment longevity

- Versatility in design and application

These advantages have made covered spandex yarn an indispensable material in modern textile production.

Comparison of Covered Spandex Yarn Types

Choosing the right type of covered spandex yarn is critical for optimizing fabric performance, comfort, and longevity in the final garment. The industry predominantly utilizes two main types: Air Covered Spandex and Polyester Covered Spandex. While both offer the essential stretch of the spandex core, their distinct manufacturing processes and covering fiber properties result in unique characteristics. The following table provides a detailed, side-by-side comparison of these two crucial yarn types, helping manufacturers and designers make informed decisions for their specific textile applications.

| Criteria | Air Covered Spandex Yarn | Polyester Covered Spandex Yarn |

| Manufacturing Technology | Utilizes air jet technology in its manufacturing process. | One of the most common types, made using traditional (mechanical) covering techniques. |

| Covering Property | Creates a looser covering using high-pressure air. | Provides excellent strength and durability. |

| Hand Feel | Softer hand feel. | Offers a generally sturdier and tougher feel. |

| Weight | Lighter weight. | Standard weight. |

| Stretch & Recovery | Enhanced stretch and recovery. | Good elasticity and recovery (thanks to the Spandex core). |

| Other Characteristics | Increased breathability. | Excellent strength and durability. |

| Good resistance to wrinkles and shrinkage. | ||

| Quick-drying capabilities. | ||

| Colorfastness and improved abrasion resistance. | ||

| Primary Applications | Products prioritizing maximum comfort and flexibility: High-end sportswear, Yoga and pilates apparel, Lightweight compression garments, Moisture-wicking underwear. | Products requiring durability and environmental resistance: Swimwear (due to durability in chlorinated environments), Activewear, and various other textile applications. |

| Sustainability Trends | Not explicitly mentioned in the provided text. | Exploring alternatives: Recycled polyester coverings, Bio-based polyester alternatives, and blends with eco-friendly fibers. |

Air Covered Spandex Yarn

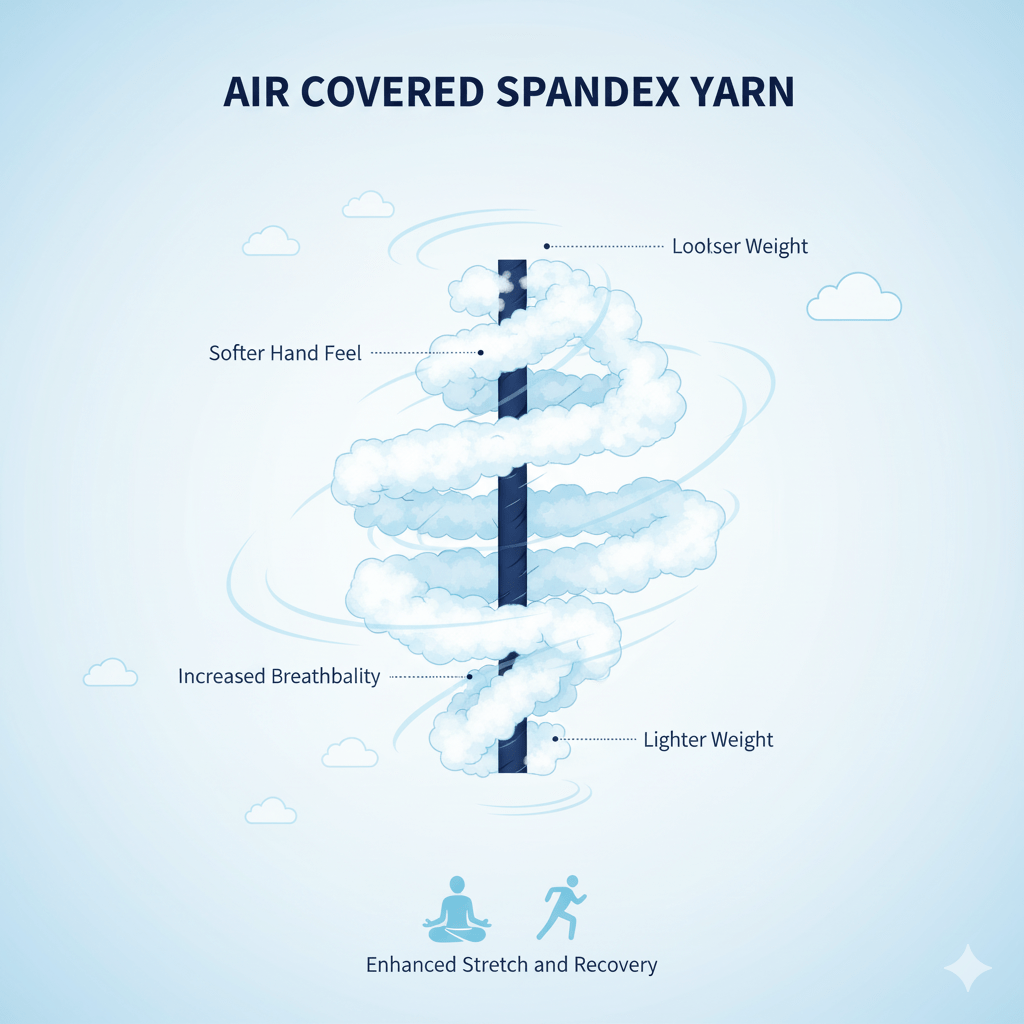

Air covered spandex yarn is a specific type of covered spandex yarn that utilizes air jet technology in its manufacturing process. This method offers unique characteristics and benefits compared to traditional covering techniques.

Air Covering Technology

The air covering process involves using high-pressure air to wrap the covering fiber around the spandex core. This technique creates a looser covering compared to mechanical methods, resulting in a yarn with distinct properties.

Characteristics of Air covered yarn

Air covered spandex yarn exhibits several unique features:

- Softer hand feel

- Increased breathability

- Lighter weight

- Enhanced stretch and recovery

These characteristics make air covered spandex yarn particularly suitable for applications where comfort and flexibility are paramount.

Applications in Performance Fabrics

Air covered spandex yarn is extensively used in the production of performance fabrics, especially those designed for:

- High-end sportswear

- Yoga and pilates apparel

- Lightweight compression garments

- Moisture-wicking underwear

The superior comfort and performance of air covered spandex yarn make it a preferred choice for manufacturers of premium athletic and leisure wear.

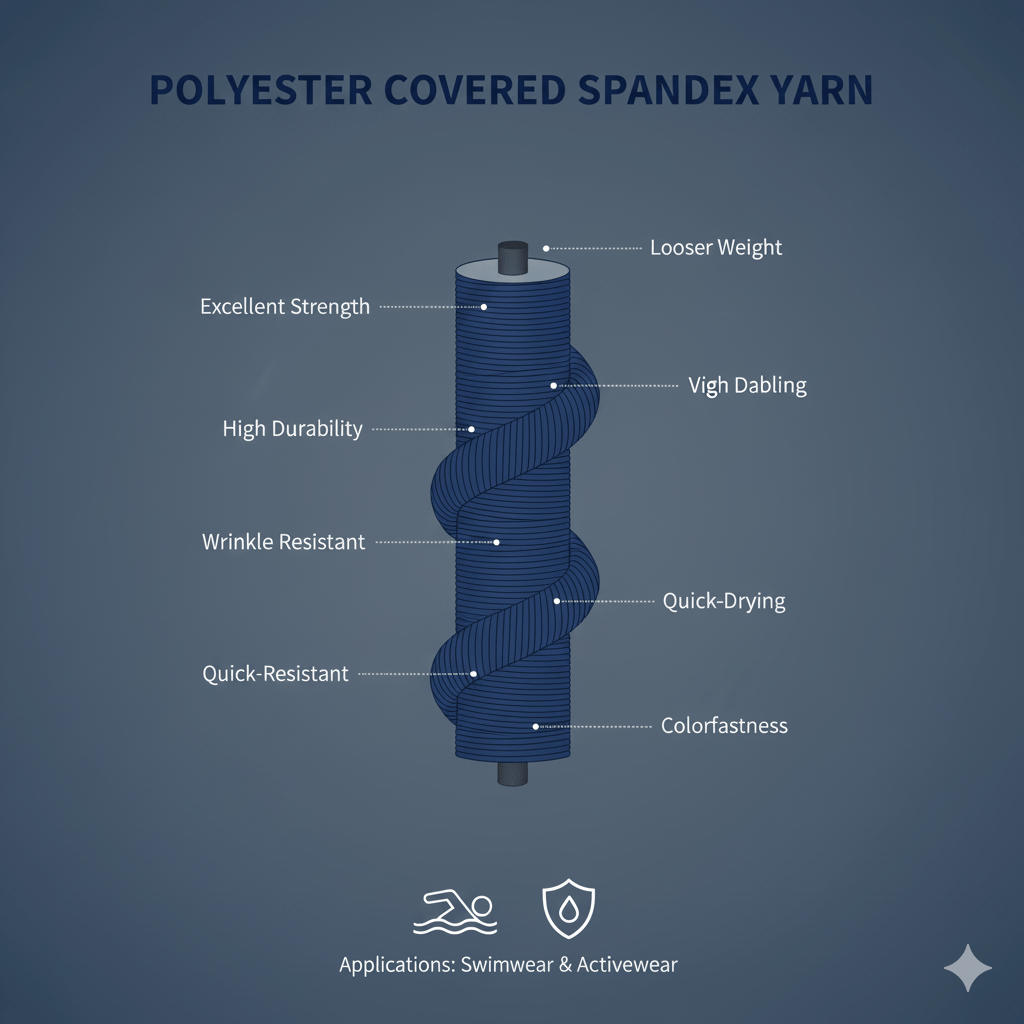

Polyester Covered Spandex Yarn

Polyester covered spandex yarn is one of the most common types of covered spandex yarn, combining the elasticity of spandex with the durability and versatility of polyester.

Properties of Polyester Covering

Polyester as a covering fiber imparts several beneficial properties to the yarn:

- Excellent strength and durability

- Good resistance to wrinkles and shrinkage

- Quick-drying capabilities

- Colorfastness

These properties make polyester covered spandex yarn a popular choice in various textile applications.

Comparison with Other Coverings

When compared to other covering materials like nylon or cotton, polyester covered spandex yarn offers:

- Better moisture management

- Improved abrasion resistance

- Greater color retention

- Enhanced durability in chlorinated environments

These advantages make it particularly suitable for swimwear and activewear applications.

Sustainable Alternatives

With growing environmental concerns, manufacturers are exploring sustainable alternatives for polyester covered spandex yarn:

- Recycled polyester coverings

- Bio-based polyester alternatives

- Blends with eco-friendly fibers

These innovations aim to reduce the environmental impact of textile production while maintaining the performance of polyester covered spandex yarn.

What is Spandex Yarn?

Spandex yarn, also known as elastane or Lycra (a brand name), is a synthetic fiber known for its exceptional elasticity. Understanding the nature of spandex yarn is crucial to appreciating the benefits of covered spandex yarn.

Chemical Composition

Spandex is a polyurethane-based polymer with a unique molecular structure that allows for extreme stretch and recovery. Its chemical composition gives it properties that are unmatched by natural fibers.

Physical Properties

Spandex yarn exhibits several remarkable physical properties:

- Ability to stretch up to 500% of its original length

- Excellent recovery after stretching

- Lightweight and soft

- Resistant to body oils and perspiration

These properties make spandex an ideal component in stretchable fabrics and garments.

Historical Development

The development of spandex in the late 1950s revolutionized the textile industry:

- Invented as an alternative to rubber

- Quickly adopted in various applications

- Continuous improvements in production and properties

Understanding the history and evolution of spandex provides context for its current applications and future developments.

Spandex Yarn Price

The price of spandex yarn is influenced by various factors and can significantly impact the cost of finished textile products.

Market Trends

Spandex yarn prices are subject to market fluctuations influenced by:

- Raw material costs

- Global demand and supply

- Production capacity

- Technological advancements

Staying informed about these trends is crucial for manufacturers and buyers in the textile industry.

Quality vs. Cost Considerations

When considering spandex yarn prices, it’s essential to balance quality and cost:

- Higher-quality spandex often commands premium prices

- Lower-cost alternatives may compromise on performance

- Long-term durability can offset initial higher costs

Making informed decisions about spandex yarn quality and price can significantly impact the final product’s performance and profitability.

Impact on Final Product Pricing

The price of spandex yarn directly affects the cost of finished textile products:

- Higher spandex content generally increases product cost

- Premium spandex yarns can justify higher retail prices

- Cost fluctuations can impact profit margins for manufacturers

Understanding these relationships is crucial for effective pricing strategies in the textile and apparel industries.

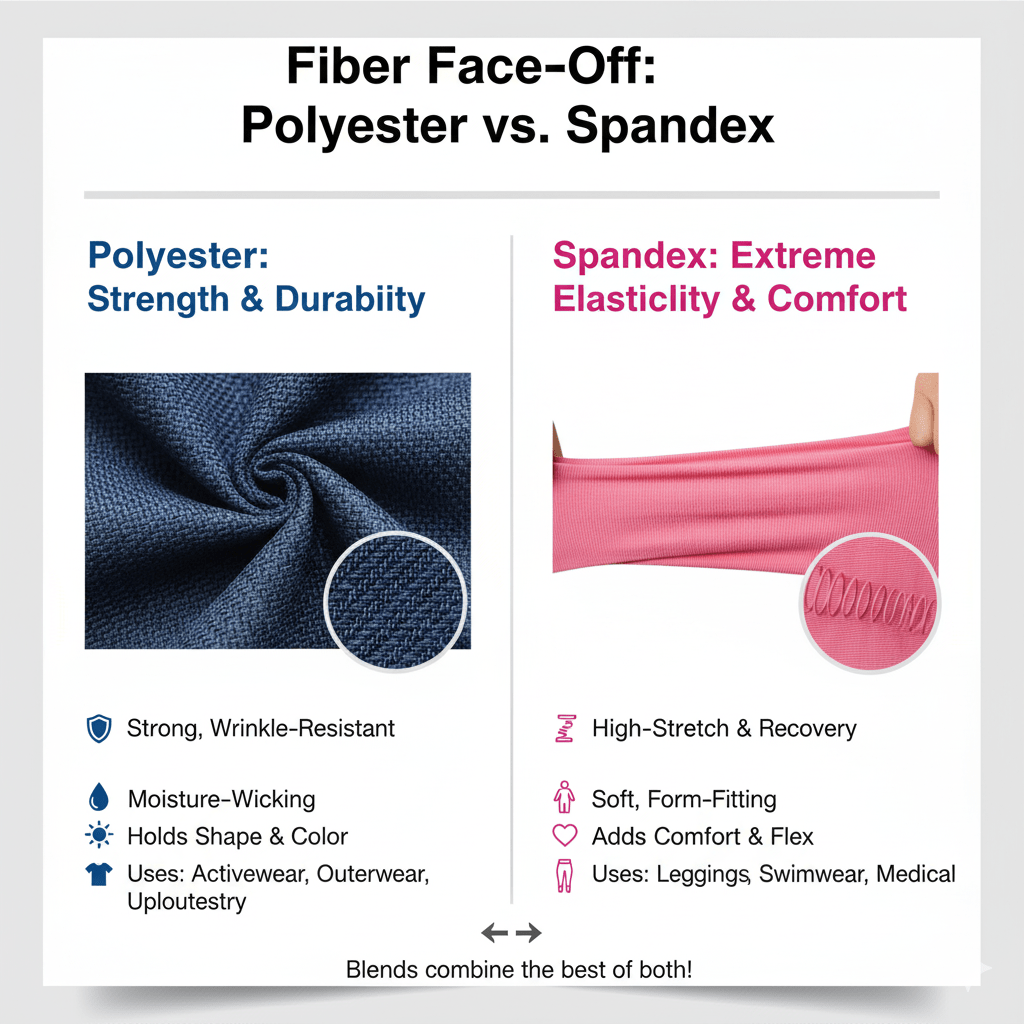

Difference Between Polyester and Spandex

While both polyester and spandex are synthetic fibers, they have distinct properties and applications in the textile industry.

Fiber Structure

The fundamental differences between polyester and spandex lie in their molecular structure:

- Polyester is a linear polymer with a rigid structure

- Spandex has a segmented structure with flexible and rigid segments

These structural differences account for the distinct properties of each fiber.

Performance Characteristics

Polyester and spandex exhibit different performance characteristics:

- Polyester offers strength and durability

- Spandex provides exceptional stretch and recovery

- Polyester is more resistant to heat and chemicals

- Spandex is more sensitive to environmental factors

Understanding these differences is crucial for selecting the appropriate fiber for specific applications.

Blending Benefits

The combination of polyester and spandex in covered spandex yarn offers synergistic benefits:

- Enhanced durability from polyester

- Improved stretch and comfort from spandex

- Better moisture management

- Increased fabric versatility

This blend of properties makes polyester covered spandex yarn a popular choice in various textile applications.

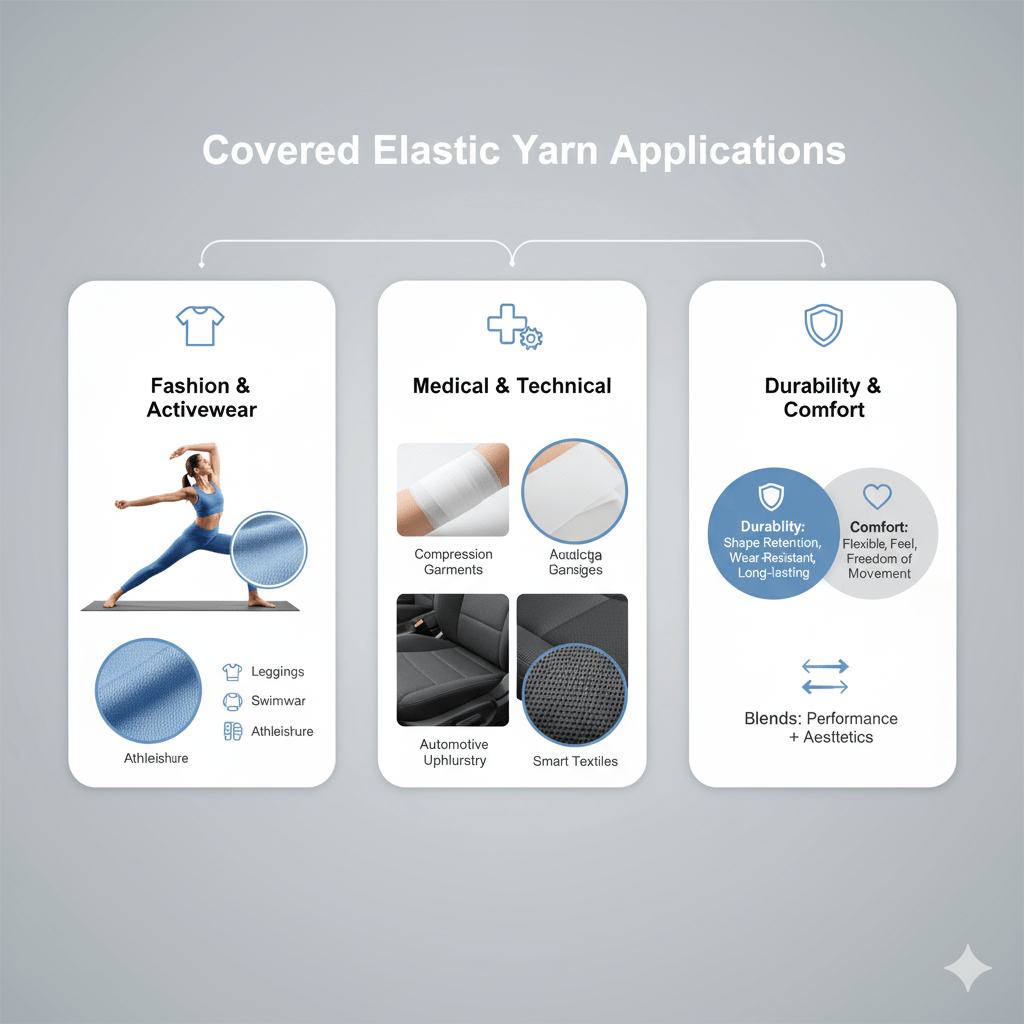

Covered Elastic Yarn

Covered elastic yarn is a broader category that includes covered spandex yarn and other elastic core yarns. Understanding the similarities and differences within this category provides valuable insights for textile professionals.

Types of Elastic Cores

Various elastic materials can be used as cores in covered elastic yarn:

- Spandex (elastane)

- Rubber

- Polyurethane elastomers

Each core material offers unique properties and is suited for different applications.

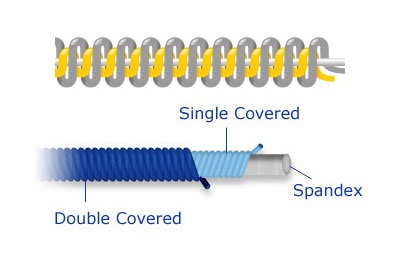

Covering Techniques

Different covering techniques can be employed in the production of covered elastic yarn:

- Single covering

- Double covering

- Air covering

- Core-spun covering

The choice of covering technique affects the yarn’s properties and performance.

Specialty Applications

Covered elastic yarn finds use in specialized applications beyond traditional textiles:

- Medical and healthcare textiles

- Industrial fabrics

- Smart textiles and wearable technology

These emerging applications showcase the versatility and potential of covered elastic yarn in various industries.

Conclusion

Covered spandex yarn, particularly polyester covered spandex yarn and air covered spandex yarn, has become an indispensable component in modern textile production. Its unique combination of stretch, recovery, and durability makes it ideal for a wide range of applications, from everyday clothing to high-performance sportswear and specialized medical textiles.

Understanding the properties, manufacturing processes, and applications of covered spandex yarn is crucial for textile professionals, designers, and consumers alike. As technology advances and sustainability concerns grow, we can expect continued innovations in covered spandex yarn production and applications, further cementing its place as a cornerstone of the textile industry.

Whether you’re a manufacturer looking to optimize your products, a designer seeking the perfect material for your creations, or a consumer interested in the technology behind your comfortable clothing, the world of covered spandex yarn offers a fascinating blend of science, engineering, and practical applications that continue to shape the fabrics of our daily lives.