In today’s demanding textile market, the pursuit of perfect fit, lasting comfort, and functional durability is paramount. Covered elastic yarn stands out as a pivotal innovation, meeting these rigorous demands through its unique hybrid structure. By masterfully combining high-performance elasticity with superior aesthetics, this yarn has become an unsung hero in countless advanced textile applications. This article will explore the essential characteristics and the vast, practical applications of covered elastic yarn across multiple industries.

Understanding Covered Elastic Yarn: A Primer

To fully appreciate its applications, one must first understand what covered elastic yarn is, how it’s made, and what makes it so unique.

What is Covered Elastic Yarn?

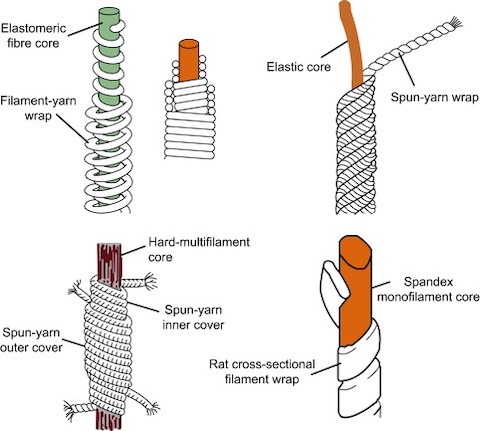

Covered elastic yarn is a composite yarn structure consisting of a core of elastane filament (such as Lycra or Spandex) that is completely wrapped or “covered” by one or more layers of non-elastic yarns. These covering yarns can be natural (like cotton or rayon) or synthetic (like polyester or nylon). The core provides the stretch and recovery, while the outer cover conceals the elastane and gives the yarn its final appearance, texture, and hand-feel.

Key Components and Manufacturing Process

The two primary components are:

- The Core: A bare spandex/elastane filament, responsible for the high elasticity and snap-back.

- The Cover: The inelastic yarn(s) that are spirally wound around the core.

The manufacturing process is typically done on specialized machinery like a covering or hollow spindle machine. The process involves precisely feeding the elastane core under controlled tension while the covering yarn(s) are twisted around it, creating a tight, uniform sheath. This can be done with a single cover (one layer) or a double cover (two layers in opposite directions) for better opacity and coverage.

Properties of Covered Elastic Yarn

The ingenious construction of covered elastic yarn results in a suite of enhanced properties that make it far superior to bare elastane. Firstly, it offers controlled and consistent elasticity, providing reliable stretch and excellent recovery power for shape retention. Moreover, the outer sheath grants superior aesthetics and comfort, effectively hiding the rubbery look of elastane and presenting a soft, skin-friendly surface that can be dyed in a wide range of colors.

Critically, the covering layer significantly improves durability by shielding the delicate elastane core from abrasion, UV exposure, and chemicals, thereby extending the functional life of the end product. This combination of durability, comfort, and aesthetic flexibility is precisely what makes it so valuable.

Applications of Covered Elastic Yarn

The exceptional properties of covered elastic yarn are not confined to a single use; they have propelled its adoption across a diverse range of fields. From the clothes we wear every day to specialized medical devices, this versatile component is the key to adding durable, comfortable, and reliable elasticity. Its application is a testament to its ability to solve complex design challenges in sectors as varied as fashion, healthcare, and industrial manufacturing.

Apparel Industry

This is the most significant application area, where covered elastic yarn is essential for fit and function.

- Intimate Apparel & Swimwear: Used in bra straps, underwire casings, bands, brief leg openings, and swimsuit linings for firm support, shape retention, and all-day comfort.

- Sportswear & Activewear: Found in waistbands on leggings and shorts, cuffs on sleeves and ankles, and entire compression garments, providing a secure, dynamic fit that moves with the athlete.

- Socks: Essential for creating comfortable, non-binding sock tops (welts) that stay up without cutting off circulation, as well as in the arch support bands.

- Ready-to-Wear: Integrated into waistbands of pants, skirts, and jeans; in cuff hems on blouses and jackets; and in turtleneck collars to maintain structure and fit.

Medical and Healthcare Industry

Here, reliability and patient comfort are paramount.

- Compression Garments: Used for post-surgical recovery (e.g., after liposuction), managing lymphedema, and treating venous disorders.

- Orthopedic Supports: Provides adjustable tension and support in knee braces, wrist supports, and athletic taping.

- Prosthetics and Orthotics: Helps create secure, comfortable, and breathable liners and suspension sleeves for prosthetic limbs.

- Medical Devices: Used in elasticated bands for respiratory masks, surgical drapes, and adjustable straps for various medical equipment.

Home Textile Industry

Elasticity adds critical functionality and convenience to home fabrics.

- Fitted Sheets: The elasticated corners, made with covered elastic yarn, ensure a snug and secure fit on mattresses of all depths.

- Furniture Slipcovers: Allows stretchable slipcovers to fit snugly over sofas and chairs, maintaining a tailored look without shifting.

- Shower Curtains: Used in weighted hems to ensure the curtain hangs properly and doesn’t billow inward.

- Mattress Protectors & Pillow Covers: Integrated into the edges to create a tight, gusseted seal.

Automotive Industry

The automotive sector utilizes this yarn in interior components where durability and fit are crucial.

- Seat Covers: Helps in creating custom-fit, stretchable seat covers that are easy to install and remove.

- Interior Trim: Used in cargo nets, parcel shelf linings, and trim components on doors or consoles that require flexibility and a clean finish.

- Headliners and Floor Mats: In certain designs, elastic components help secure mats or interior panels in place.

Other Applications

The use of covered elastic yarn extends to other niche areas, including:

- Technical Textiles: In protective workwear, cut-resistant gloves, and smart clothing with integrated sensors.

- Accessories: In adjustable hat bands, mask ear loops, glove cuffs, and drawstrings for bags and backpacks.

- Footwear: As elastic laces for slip-on shoes, in gore panels for a snug fit, and in certain knitted shoe uppers.

Conclusion

As we have explored, the influence of covered elastic yarn is both profound and far-reaching. Its specific properties—including reliable controlled elasticity, enhanced comfort from its soft sheath, and exceptional durability against wear and chemicals—directly address the core needs of modern textiles. From ensuring the perfect fit of a surgical compression garment to providing the lasting comfort of a sock’s waistband and the secure hold of a fitted sheet, this yarn is an indispensable engineering solution.

As a leader in the textile yarn sector, we possess the deep technical expertise to provide high-quality, customized covered elastic yarn solutions tailored to your product’s precise performance and aesthetic requirements. We understand the nuances of fiber selection, core tension, and cover twisting that dictate the final yarn’s behavior.

Ready to leverage the precise elasticity and durability of covered elastic yarn in your products? Contact our specialists today to discuss your application and receive tailored samples that demonstrate the difference quality makes.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com