In the intricate world of textiles, achieving the perfect blend of comfort, fit, and durability is a constant pursuit. Among the many engineered yarns that make this possible, Conventional Covered Yarn stands out as a time-tested and reliable solution. From the stretch in your favorite jeans to the support in your activewear, this versatile yarn plays a crucial role. But what exactly is it, and why does it remain so popular? This comprehensive guide will unravel everything you need to know about Conventional Covered Yarn.

What is Conventional Covered Yarn?

In the pursuit of creating textiles that combine elasticity with durability, conventional covered yarn stands as a foundational and time-tested manufacturing solution. It represents a classic approach to engineering yarns for specific performance characteristics, predating more modern air-covering methods. Understanding its structure and production is key to appreciating its role in the textile industry.

At its core, Conventional Covered Yarn is a composite yarn made by wrapping or “covering” a core filament with one or more outer layers of yarn. The structure is straightforward yet ingenious:

- The Core: Typically, this is an elastic filament like Spandex or Lycra, which provides the stretch and recovery properties.

- The Cover: This is a non-elastic yarn, such as nylon, cotton, or polyester, that is spirally wound around the core. This cover protects the delicate elastic core, adds aesthetic appeal, and provides the final fabric’s handfeel and appearance.

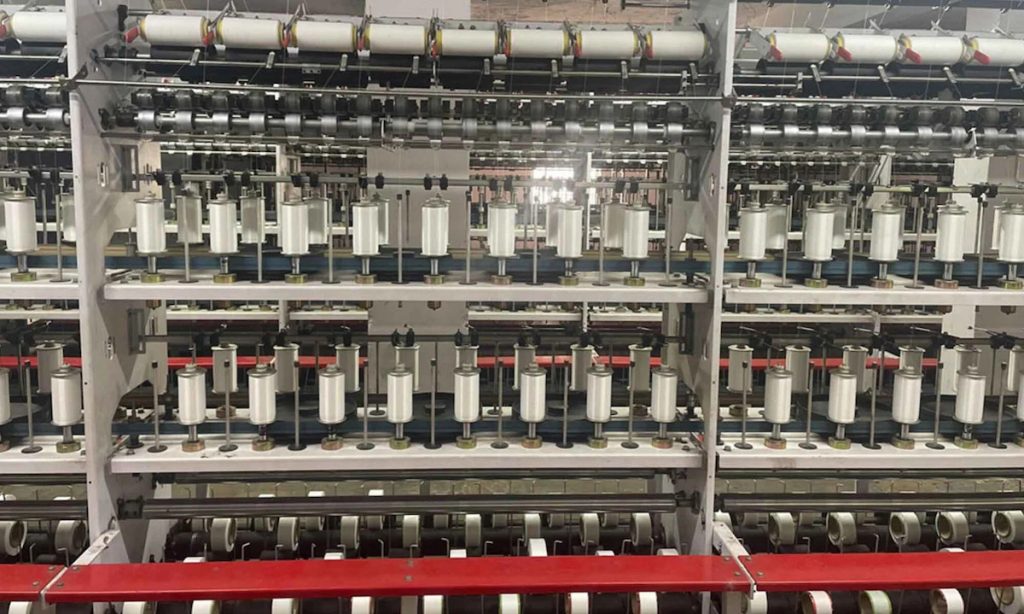

Unlike its modern counterpart, Air Covered Yarn (which uses a jet of air to intermingle the fibers for a softer feel), Conventional Covered Yarn is produced using mechanical ring spinning or hollow spindle techniques, resulting in a tightly wrapped, robust structure.

In summary, conventional covered yarn is defined by its robust mechanical construction, where a protective sheath is spirally wound around a functional core. This method produces a highly durable and resilient yarn, making it an indispensable choice for applications where consistent performance and protection of the elastic core are paramount. Despite the emergence of softer alternatives, the unique advantages of conventional covered yarn ensure it remains a vital and reliable component in the production of a wide range of elastic textiles.

The Manufacturing Process of Conventional Covered Yarn

The production of Conventional Covered Yarn is a masterclass in precision engineering, transforming a stretchy core and a protective sheath into a unified, high-performance thread through a tightly controlled mechanical process. It is two-step process:

- Core Feeding and Stretching: The spandex core is fed under high tension and stretched to a predetermined ratio (known as the draft ratio). This stretching is crucial as it activates the elastic potential of the spandex.

- Covering: Simultaneously, the hard yarn (the cover) is twisted and wrapped around the stretched core using a spinning ring or a hollow spindle. This creates a tight, helical sheath that locks the core in its stretched state.

Once the yarn is relaxed after production, the spandex core tries to return to its original length, causing the covering yarn to buckle slightly. This is what gives the yarn its signature stretch and recovery.

In essence, this mechanical process is what defines the yarn’s robust character. The result is a highly durable and resilient elastic yarn, prized for its consistent performance and powerful recovery in demanding applications.

Advantages and Disadvantages of Conventional Covered Yarn

As a cornerstone of elastic yarn production, Conventional Covered Yarn offers a distinct set of benefits shaped by its mechanical manufacturing process. A clear analysis of its strengths and limitations is essential for selecting the right material for any textile application.

Key Advantages:

- Superior Durability and Recovery: The tight wrap offers excellent protection to the spandex core, leading to outstanding resistance against abrasion and snagging. It also provides strong, consistent recovery power, meaning garments retain their shape wash after wash.

- Excellent Aesthetics and Coverage: The covering process fully conceals the core, resulting in a smooth, uniform yarn with great color vibrancy and a clean visual finish.

- Dimensional Stability: Fabrics made with this yarn are less prone to excessive shrinking or warping during washing and dyeing processes.

- Cost-Effectiveness: The manufacturing machinery for conventional covering is widely available and often more economical than advanced air-covering systems, making it a cost-efficient choice.

Potential Disadvantages:

- Heavier Handfeel: The tight wrapping can make the yarn feel denser and less soft compared to the fluffy, lightweight feel of Air Covered Yarn.

- Limited Breathability: The dense structure can reduce the fabric’s overall breathability.

- Slower Production Speed: The mechanical twisting process is generally slower than the air-jet method.

In summary, the choice of Conventional Covered Yarn presents a clear trade-off: it delivers unmatched durability, power, and cost-efficiency at the potential expense of ultimate softness and a lightweight handfeel. This makes it an ideal and reliable solution for applications where rugged performance and shape retention are the highest priorities. It is precisely these characteristics that make it the material of choice for several key applications in the textile industry.

Common Applications of Conventional Covered Yarn

The unique properties of Conventional Covered Yarn make it ideal for a wide range of applications where durability and control are paramount.

- Sportswear and Activewear: Used in leggings, sports bras, and athletic tops where strong support and shape retention are critical during movement.

- Stretch Denim: It is the go-to choice for adding stretch to jeans, providing comfort without compromising the rugged denim look and feel.

- Lingerie and Shapewear: Its powerful recovery and smooth finish are perfect for foundation garments that require firm control and a sleek silhouette under clothing.

- Socks and Accessories: Frequently used in the cuffs of socks for durable elasticity and in various elastics for waistbands and bra straps.

Conclusion

Conventional Covered Yarn may be a traditional technology, but its value in the modern textile landscape is undeniable. It remains the workhorse for applications that demand robust elasticity, superior shape retention, and a polished finish. While newer technologies offer alternative sensations, the reliability, durability, and cost-effectiveness of Conventional Covered Yarn ensure its continued relevance in creating high-quality, long-lasting stretch garments. Understanding its properties allows designers and manufacturers to make informed choices, ultimately leading to better products for consumers.

Contact us today to experience the quality and durability of our Conventional Covered Yarn firsthand. Request a free sample now to feel the difference!

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com