In textile manufacturing, the choice between core spun yarn and covered yarn significantly impacts fabric performance, durability, and cost-effectiveness. While both incorporate elastane for stretch, their manufacturing processes and resulting characteristics differ substantially.

This comprehensive guide examines the core spun yarn vs covered yarn debate, providing clear insights to help manufacturers select the optimal solution for their specific applications.

Understanding Core Spun Yarn vs Covered Yarn

What Is Core Spun Yarn vs Covered Yarn?

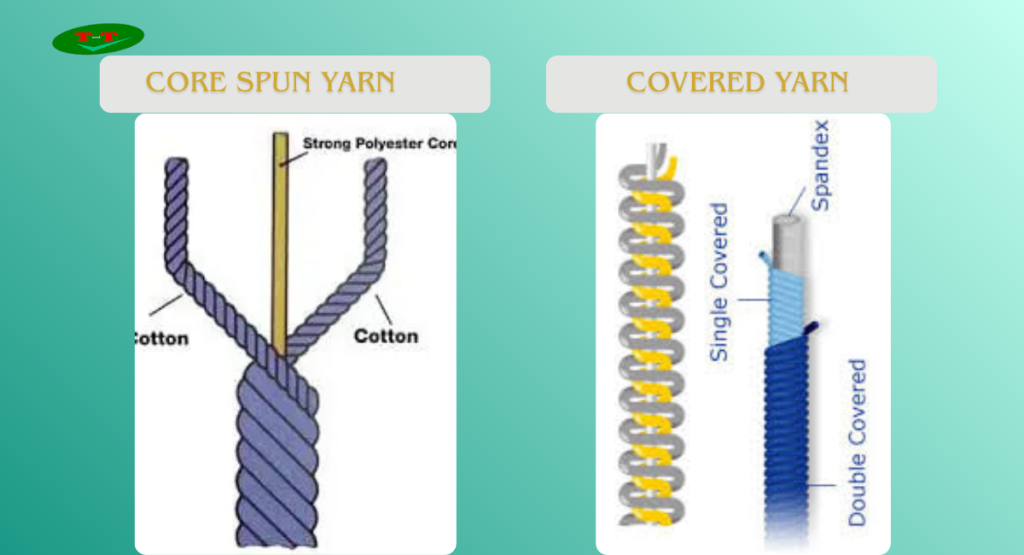

- Core spun yarn features a central elastane core completely surrounded by staple fibers during the spinning process. In this construction, the sheath fibers are twisted around the spandex core using traditional ring spinning or other spinning systems, creating a unified yarn structure where the core and sheath are integrally bonded. This manufacturing method results in a durable yarn with the spandex permanently encapsulated within the sheath fibers.

- Covered yarn consists of a spandex core wrapped by one or more already-spun yarns using covering machines. Unlike core spinning, this process involves pre-made yarns being twisted or air-entangled around the elastane core. Covered yarns typically come in two variations: single covered (one wrapping layer) and double covered (two wrapping layers in opposite directions), with the latter providing superior coverage and balance.

The fundamental distinction in the core spun yarn vs covered yarn comparison lies in their manufacturing approach and final structure. Core spun yarn integrates the sheath during initial spinning, while covered yarn wraps pre-spun yarns around the core. This fundamental difference translates to variations in softness, durability, production cost, and ideal applications that manufacturers must consider when selecting between these two elastomeric yarn types.

Comparison Between Core Spun Yarn vs Covered Yarn

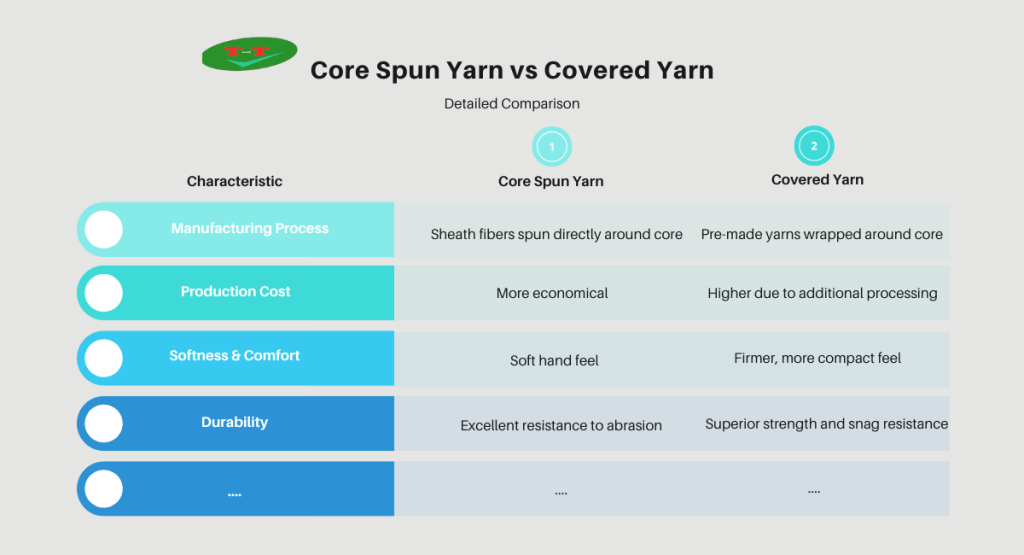

| Parameter | Core Spun Yarn | Covered Yarn |

| Manufacturing Process | Sheath fibers spun directly around core | Pre-made yarns wrapped around core |

| Production Cost | More economical | Higher due to additional processing |

| Softness & Comfort | Soft hand feel | Firmer, more compact feel |

| Durability | Excellent resistance to abrasion | Superior strength and snag resistance |

| Elasticity & Recovery | Good stretch properties | Excellent stretch and recovery |

| Opacity | Good core coverage | Superior coverage, no grin-through |

| Twist Stability | Moderate torque | Low torque (especially double covered) |

| Production Speed | Faster manufacturing | Slower production process |

| Common Applications | Denim, twills, workwear, t-shirts | Activewear, intimate apparel, medical textiles |

Which Should You Choose — Core Spun Yarn vs Covered Yarn?

The decision between core spun yarn vs covered yarn depends entirely on your specific product requirements, budget constraints, and performance expectations. Here’s a detailed breakdown to guide your selection:

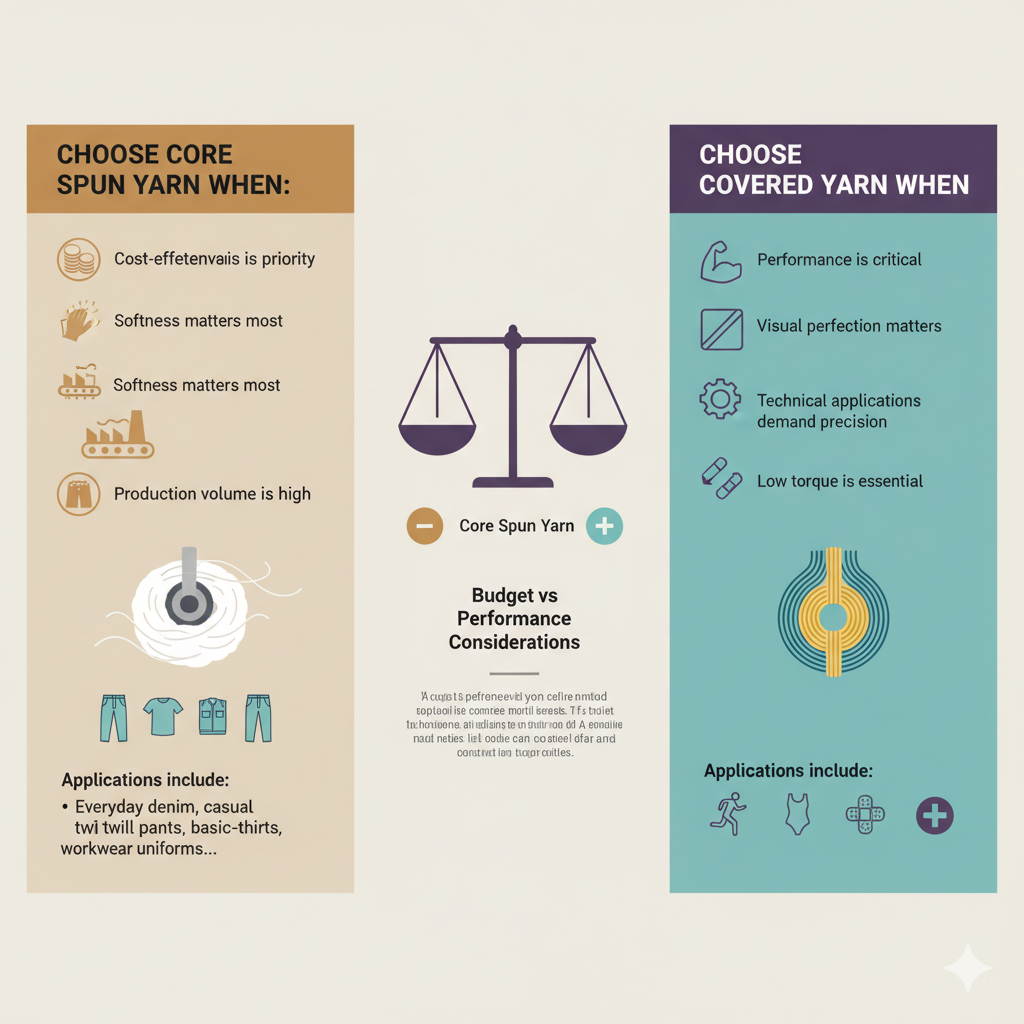

Choose Core Spun Yarn When:

- Cost-effectiveness is priority: Core spun yarn typically offers better value for budget-conscious projects without compromising essential stretch properties

- Softness matters most: For garments requiring direct skin contact where comfort is paramount, core spun yarn‘s softer hand feel provides superior wearer comfort

- Production volume is high: The faster manufacturing process makes core spun yarn ideal for large-scale production runs with tight deadlines

- Applications include: Everyday denim, casual twill pants, basic t-shirts, workwear uniforms, and household textiles where moderate stretch suffices

Choose Covered Yarn When:

- Performance is critical: For high-stretch applications requiring excellent recovery and shape retention, covered yarn delivers superior mechanical properties

- Visual perfection matters: When you cannot tolerate “grin-through” (visible spandex) even at maximum stretch, double covered yarn ensures perfect opacity

- Technical applications demand precision: Medical textiles, compression garments, and performance activewear benefit from covered yarn‘s consistent elasticity

- Low torque is essential: For knitted fabrics where spirality must be minimized, double covered yarn‘s balanced construction prevents twisting

- Applications include: Premium activewear, seamless garments, swimwear, intimate apparel, and technical textiles requiring reliable performance

Budget vs Performance Considerations

While core spun yarn generally costs 15-25% less than covered yarn, the price difference reflects the enhanced performance characteristics. Evaluate whether your application justifies the additional investment by considering the garment’s intended use, lifespan expectations, and quality requirements. For disposable fashion or seasonal items, core spun yarn often provides sufficient performance. For technical apparel or premium products, covered yarn‘s advantages typically justify the higher cost.

Need help selecting the ideal covering yarn for your application? Contact our technical experts today for personalized recommendations and samples tailored to your specific requirements.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

Conclusion

The core spun yarn vs covered yarn decision ultimately hinges on balancing cost, performance, and application requirements. Core spun yarn offers an economical solution with good stretch properties and softness ideal for everyday apparel and budget-conscious projects. Covered yarn, while more expensive, delivers superior performance, perfect opacity, and excellent recovery for technical applications and premium products.

Understanding these key differences enables manufacturers to make informed decisions that optimize both quality and cost-effectiveness. By carefully evaluating your specific needs against each yarn type’s characteristics, you can select the ideal elastomeric yarn solution that enhances your product’s performance and market competitiveness.

Still uncertain about the best choice for your project? Contact our yarn specialists today for personalized guidance and request complimentary samples of both core spun yarn and covered yarn to evaluate their performance in your specific application.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread