In the dynamic world of modern textiles, the demand for fabrics that offer more than just basic comfort is higher than ever. Performance, durability, and specific functional properties are now paramount. At the heart of this innovation are engineered yarns, with elastic and multi-functional varieties playing a critical role. For manufacturers, designers, and sourcing professionals, understanding the nuances of these yarn structures is not just academic—it’s a commercial necessity that directly impacts product quality, cost, and customer satisfaction.

Two terms that are fundamental in this realm, yet often a source of confusion, are Core Spun Yarn and Spandex Covered Yarn. While frequently mentioned together, they are not interchangeable. This definitive guide will cut through the complexity, comparing these two powerhouses directly. We will clarify their relationship, break down their differences in structure and performance, and provide a practical framework to help you select the perfect yarn for your next production run.

What Is Core Spun Yarn?

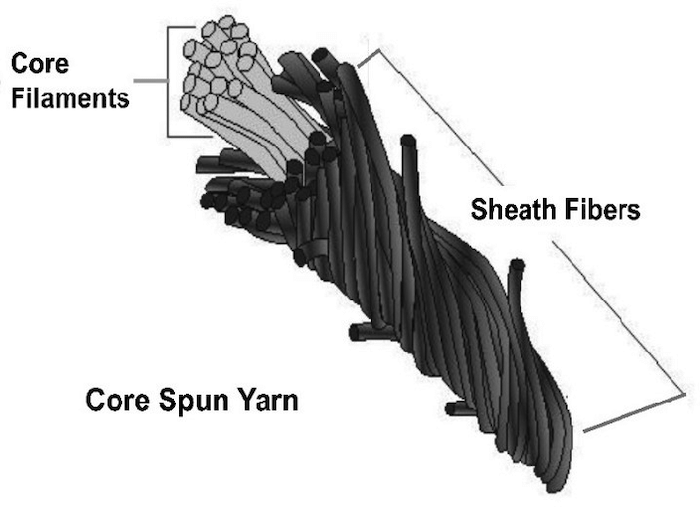

Core Spun Yarn is a sophisticated composite yarn engineered for performance. It is constructed with two distinct components:

- The Core: A central filament or bundle of filaments that acts as the backbone, providing the yarn’s primary functional property. This core can be made from strong materials like polyester or nylon for tensile strength, or from elastic filaments like spandex for stretch.

- The Sheath: An outer layer of staple fibers (such as cotton, rayon, or polyester) that is spun or wrapped tightly around the core. The sheath defines the surface characteristics of the final fabric, including its handfeel, aesthetic appearance, dyeability, and comfort against the skin.

The primary goal of core spinning is synergy—to combine the best attributes of two different materials into a single, superior yarn. For instance, it can merge the strength of a polyester core with the soft, natural feel of a cotton sheath.

What Is Spandex Covered Yarn?

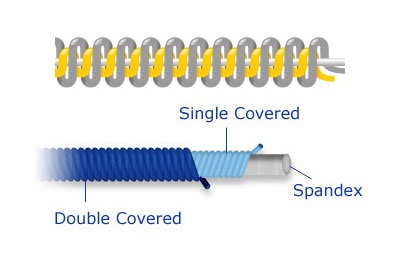

Spandex Covered Yarn is a highly specialized and critical type of core spun yarn. It is designed with one specific purpose: to deliver exceptional, durable elasticity.

- The Core: In this case, the core is exclusively a spandex filament (e.g., Lycra or Elaspan). This provides the powerful, consistent stretch and recovery.

- The Sheath/Cover: The spandex core is encased by a tightly wrapped outer yarn, typically a fine and strong filament like nylon or polyester, though cotton is sometimes used for a softer hand. This cover is crucial for protecting the delicate spandex from abrasion, chemicals during dyeing, and UV degradation, thereby ensuring the longevity of the elastic function.

In essence, while all spandex covered yarns are core spun, they represent the premium, specialized segment dedicated to high-performance stretch.

Relationship Between Core Spun Yarn and Spandex Covered Yarn

The relationship between these two is hierarchical. Core Spun Yarn is the broad, overarching category—a versatile manufacturing technology. Spandex Covered Yarn is a specific, application-driven product within that category.

The following diagram illustrates this relationship clearly:

Explanation of the Diagram:

- Core-Spun Yarn (The largest box): This is the general concept of a yarn structure, defined by its manufacturing method: it has a central “core” and an outer “sheath” that wraps around it.

- Classified by Core Material (The central branch): Core-Spun Yarn is categorized into SMALLER, MORE SPECIFIC types based on the material that makes up its core. This is the key point.

- Spandex Covered Yarn: It is ONE TYPE of Core-Spun Yarn, characterized by a core made from Spandex filament.

- Poly-Core Yarn & Other Types: When the core is Polyester, Nylon, or Cotton, it is still a Core-Spun Yarn, but it is NOT a Spandex Covered Yarn. These types often emphasize tensile strength or other properties rather than elasticity.

Structure of Spandex Covered Yarn (The detailed frame): This is a “close-up” showing the specific composition of this yarn type. It always has:

- Core: Spandex → To provide elastic stretch and recovery.

- Sheath/Cover: Typically Nylon, Cotton, or Polyester → To protect the delicate spandex core and define the fabric’s handfeel and surface aesthetics.

Technical Conclusion:

Core-Spun Yarn is a yarn manufacturing method.

Spandex Covered Yarn is a specific product created by that method, defined by its spandex core.

Manufacturing Process

While both Core Spun Yarn and Spandex Covered Yarn fall under the umbrella of composite yarns, their manufacturing journeys diverge in critical ways that define their final character and performance. Understanding these nuances in production is not just a matter of technique, but the key to unlocking why one yarn excels in comfort and the other in power and precision.

- Core Spun Yarn: This is primarily produced on specialized ring spinning or hollow spindle systems. The core fiber is fed under controlled tension, and the sheath fibers are twisted around it. The process is optimized for the reliable combination of two dissimilar materials into a cohesive, unified yarn.

- Spandex Covered Yarn: This is a more precise and demanding sub-process of core-spinning. It requires extremely exact control over the spandex draft ratio—the precise stretching of the spandex filament before it is covered. This ensures the elastic potential is fully activated and locked in. The wrapping integrity must also be exceptionally high to guarantee the core is fully protected, resulting in a robust yarn built for long-term performance.

Strategic Application in Manufacturing: Matching Yarn to End-Use

The ultimate performance of a textile is determined by selecting the right yarn. Choosing between Spandex Covered Yarn or other Core-Spun Yarns is a critical application-driven decision. This guide outlines the ideal uses for each to ensure optimal fabric performance.

When to Choose Spandex Covered Yarn:

Select this yarn when your design demands reliable, high-power stretch and superior shape retention. Its robust structure ensures long-lasting performance under stress.

Ideal Applications:

- High-Performance Activewear: Leggings, sports bras, and athletic tops.

- Premium Stretch Denim: Jeans that must maintain their shape without bagging.

- Compression Garments & Shapewear: Where powerful, controlled elasticity is the primary function.

- Technical Uniforms: Workwear requiring durability and freedom of movement.

When to Choose Other Core-Spun Yarns:

Opt for these versatile yarns when you need to blend material properties without making high-power stretch the central feature.

Ideal Applications:

- Sewing Threads: A polyester core for strength with a cotton sheath for smoothness.

- Wrinkle-Resistant Shirting: A rigid filament core for structure, wrapped in cotton for comfort.

- Enhanced Comfort Fabrics: Blending a moisture-wicking core with a soft, natural sheath.

Conclusion

In summary, the distinction is clear: Core Spun Yarn is a versatile manufacturing technology for creating multi-functional yarns, while Spandex Covered Yarn is a specialized product within that family, designed specifically for uncompromising elasticity. The former is a versatile toolkit; the latter is your precision instrument for stretch.

Understanding this relationship empowers you to make smarter, more strategic sourcing decisions. Moving forward, use the specific terms to communicate your needs clearly with suppliers. Specify “spandex covered yarn” when elite stretch is required, and “core-spun yarn” when seeking a blend of properties like strength and comfort.

Ready to specify the perfect yarn for your next collection and leverage expert technical support? Contact our team today for a personalized consultation and discover how our high-performance Core Spun and Spandex Covered Yarns can elevate your products.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com