In the pursuit of advanced textile performance, core yarn stands out as a fundamental innovation, engineered to combine the best properties of different fibers into a single, superior thread. This composite yarn is strategically designed to leverage the strength of a core filament, typically wrapped with a staple fiber sheath, creating materials that excel in both durability and comfort.

Understanding its structure, manufacturing process, and diverse applications is crucial for anyone involved in modern textile development. This overview will delve into the essential aspects that make core yarn a pivotal material in the technical textiles landscape.

What is Core Yarn?

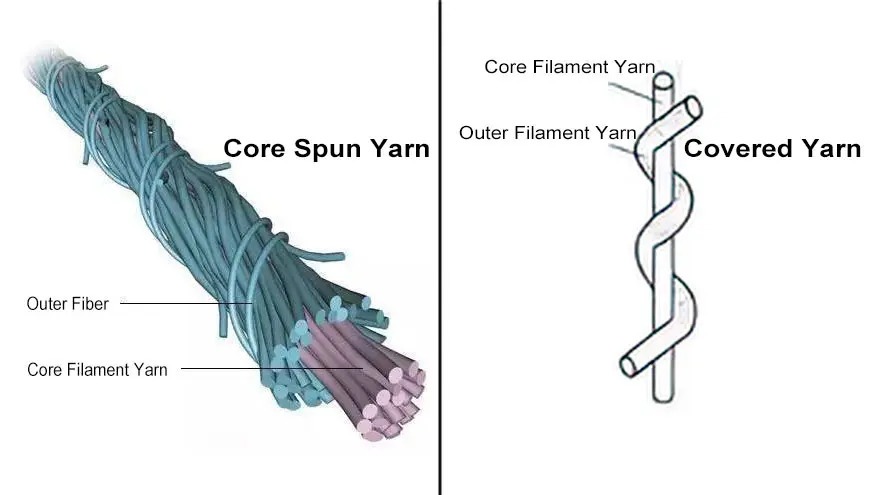

Core Yarn, also known as core-spun yarn, is an advanced composite yarn engineered for high performance. It is constructed from two distinct components: a central filament that acts as the “core” and an outer layer of staple fibers that forms the “sheath” or “covering”. This innovative structure combines the superior properties of both materials, resulting in a final yarn that is stronger, more durable, and more functional than conventional spun yarns. It is a fundamental material in modern textiles, enabling the production of fabrics that meet specific demands for elasticity, strength, and comfort.

Main Types of Core Yarn

The classification of core yarn is not limited to a single method. In fact, several criteria can be used, each offering a different perspective and serving a specific purpose in material selection, production planning, and product development.

Here are the primary ways to classify core yarn, from the most common to more specific methods:

By Core Material

This is the most fundamental and practical classification, directly determining the yarn’s key performance characteristic.

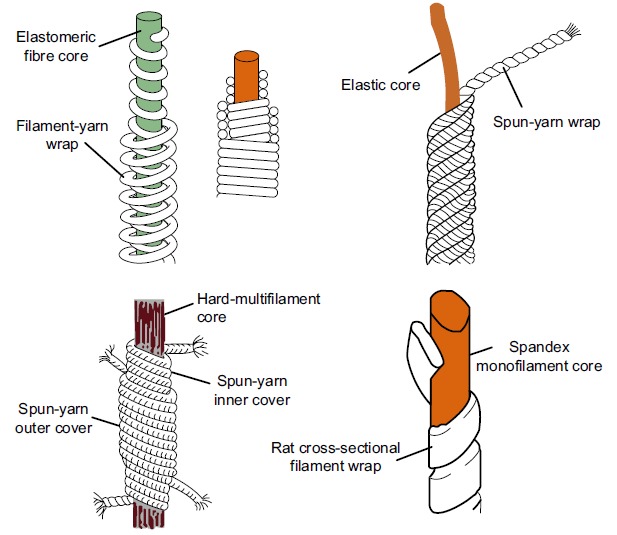

- Spandex Core Yarn: This is the most common type. It features a Spandex (also known as Elastane or Lycra) filament as the core, which is then wrapped with staple fibers like cotton, polyester, or rayon. The primary function of the Spandex core is to provide exceptional elasticity and recovery.

- Filament Core Yarn (Non-Spun Yarn): This type uses a continuous, non-elastic filament—such as polyester or nylon—as the core. The core is then covered with a sheath of soft staple fibers like cotton. The main purpose here is to provide high tensile strength and stability while maintaining a soft, natural feel.

- Staple Fiber Core Yarn: Uses a bundle of staple fibers as the core, often wrapped with a filament to bind it. The goal is to enhance processability or create specific aesthetic effects.

By Production Technology and Structural Bond

This classification is crucial for manufacturers and engineers as it defines the manufacturing process and the resulting yarn structure.

- Covered Yarn: Produced on a covering machine where a sheath yarn is wound around an elastic core.

- Single Cover: One layer of wrapping. Less stable.

- Double Cover: Two layers wrapped in opposite directions. Superior stability and recovery, used for high-quality garments.

- Core-Spun Yarn (or Core-Spun Filament Yarn): Produced on a modified ring spinning frame. Staple fibers are twisted around a stationary filament core, creating a very strong bond and a natural cotton-like feel.

- Fancy Core Yarn: Uses the core yarn principle for aesthetic purposes. A stable core is wrapped with an “effect” yarn (e.g., slub, loop, multi-colored) to create texture and visual interest.

By Sheath Material

This classification focuses on the outer hand-feel, comfort, and aesthetic properties of the yarn.

- Natural Fiber Sheath: The core is covered with cotton, wool, or silk. This provides breathability, moisture absorption, and a natural, comfortable hand-feel.

- Synthetic Fiber Sheath: The core is covered with polyester, acrylic, or rayon. This can enhance durability, color fastness, or provide specific functional properties like wicking.

- Blended Fiber Sheath: The sheath itself is a blend of different fibers (e.g., Cotton/Polyester) to combine the benefits of both.

In summary, there is no single number of ways to classify core yarn, as the system is multi-faceted. The most effective way to describe a core yarn is often to combine these classifications. For example, a yarn could be described as a “Double-Covered, Elastomeric Core Yarn with a Cotton Sheath“. This multi-criteria approach provides a complete picture of the yarn’s nature, performance, and intended use.

Key Applications of Core Yarn

The unique composite structure of core yarn makes it an indispensable material across a vast spectrum of the textile industry. By strategically combining the functional properties of the core with the aesthetic and comfort qualities of the sheath, core yarn solves specific performance challenges that single-component yarns cannot address. Its applications are a direct translation of its technical benefits into real-world solutions, primarily dominating the following sectors:

- Stretch Apparel: Core yarn with a Spandex core is essential for activewear, denim, and intimate apparel, providing critical elasticity, comfort, and superior shape retention.

- Durable Workwear: Utilizing a strong filament core (e.g., polyester), this type of core yarn delivers high tensile strength and abrasion resistance for uniforms and workwear, while the soft sheath maintains wearer comfort.

- Technical Textiles: In industrial and medical textiles, core yarn is used in sewing threads, compression bandages, and composites, where reliability, strength, and specific functional properties are paramount.

- Home Furnishings: Fancy core yarns create decorative textures in upholstery, while strong core constructions enhance the durability of carpets and furnishing fabrics.

In conclusion, the applications of core yarn are a testament to its engineered versatility, from enabling everyday comfort in clothing to ensuring performance in technical end-uses, core yarn proves to be a fundamental and adaptable solution in modern textile manufacturing.

Conclusion

Ultimately, Core Yarn is a pinnacle of textile engineering that solves complex performance challenges. By intelligently combining a functional core with a comfortable sheath, it creates materials that are greater than the sum of their parts. Whether the goal is superior stretch, unmatched strength, or enhanced durability, Core Yarn provides a reliable and efficient solution, solidifying its role as a critical component in the future of advanced fabrics.

Ready to Innovate Your Fabric Collection?

Explore the potential of Core Yarn for your next product line. Contact us today to discuss how our high-quality solutions can enhance the performance, comfort, and durability of your textiles.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com