The evolution of textile technology has brought forth remarkable innovations, with covered elastic yarn standing at the forefront of modern fabric engineering. This versatile component combines elasticity and durability, revolutionizing the way we approach garment manufacturing and textile applications. The integration of covered elastic yarn has transformed various industries, from fashion to medical textiles, offering unprecedented levels of comfort and functionality. Let’s explore the secrets of covered elastic yarn applications in detail.

Covered elastic yarn

The foundation of modern textile elasticity lies in the intricate world of covered elastic yarn, a technological marvel that has revolutionized fabric production. This innovative material combines the stretching capabilities of elastomeric cores with the protective and aesthetic qualities of covering fibers, creating a versatile component that serves multiple industries and applications.

Manufacturing Process and Core Components

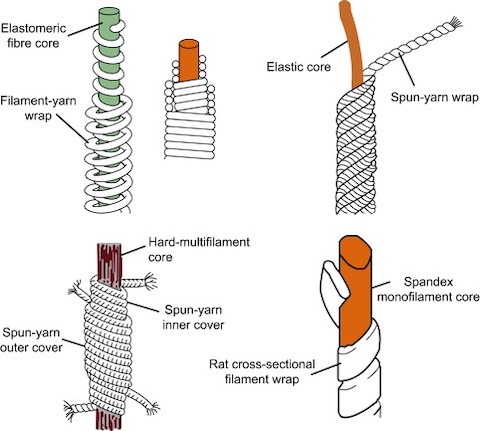

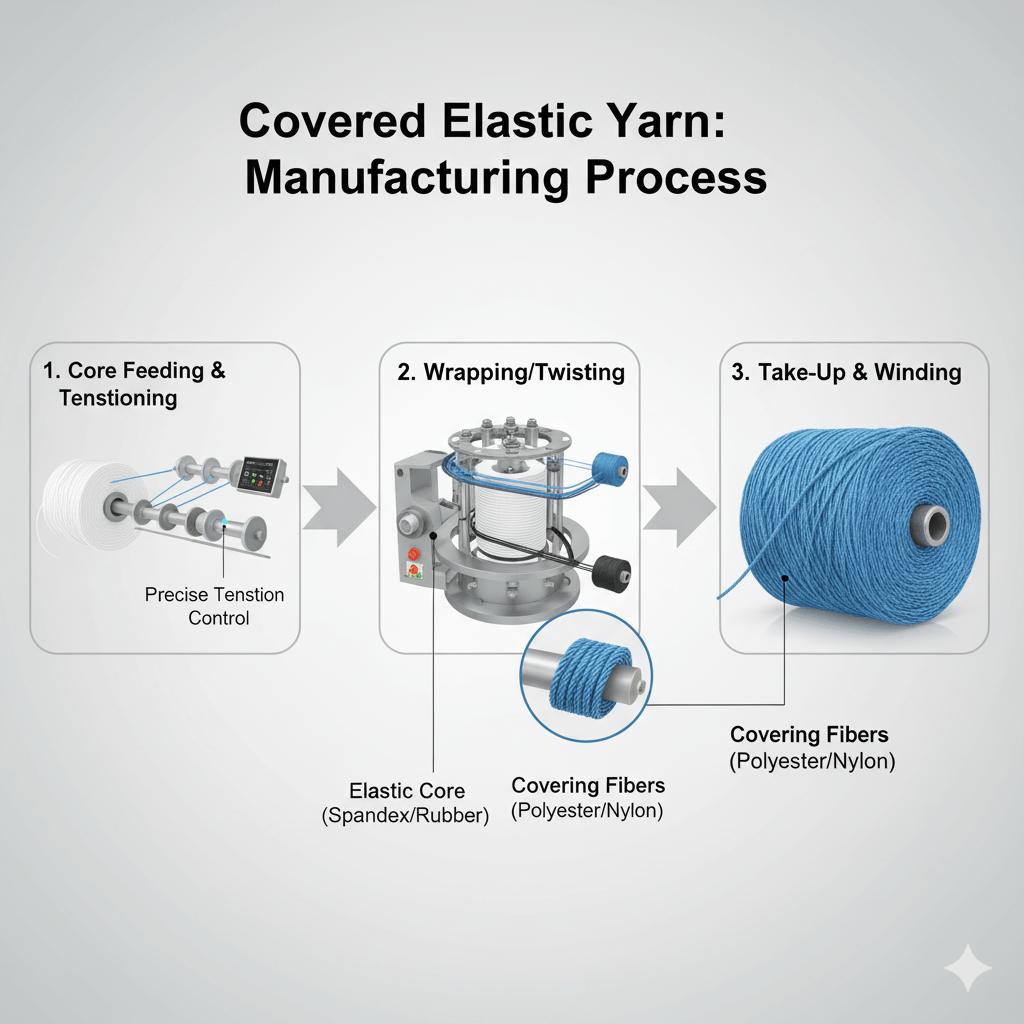

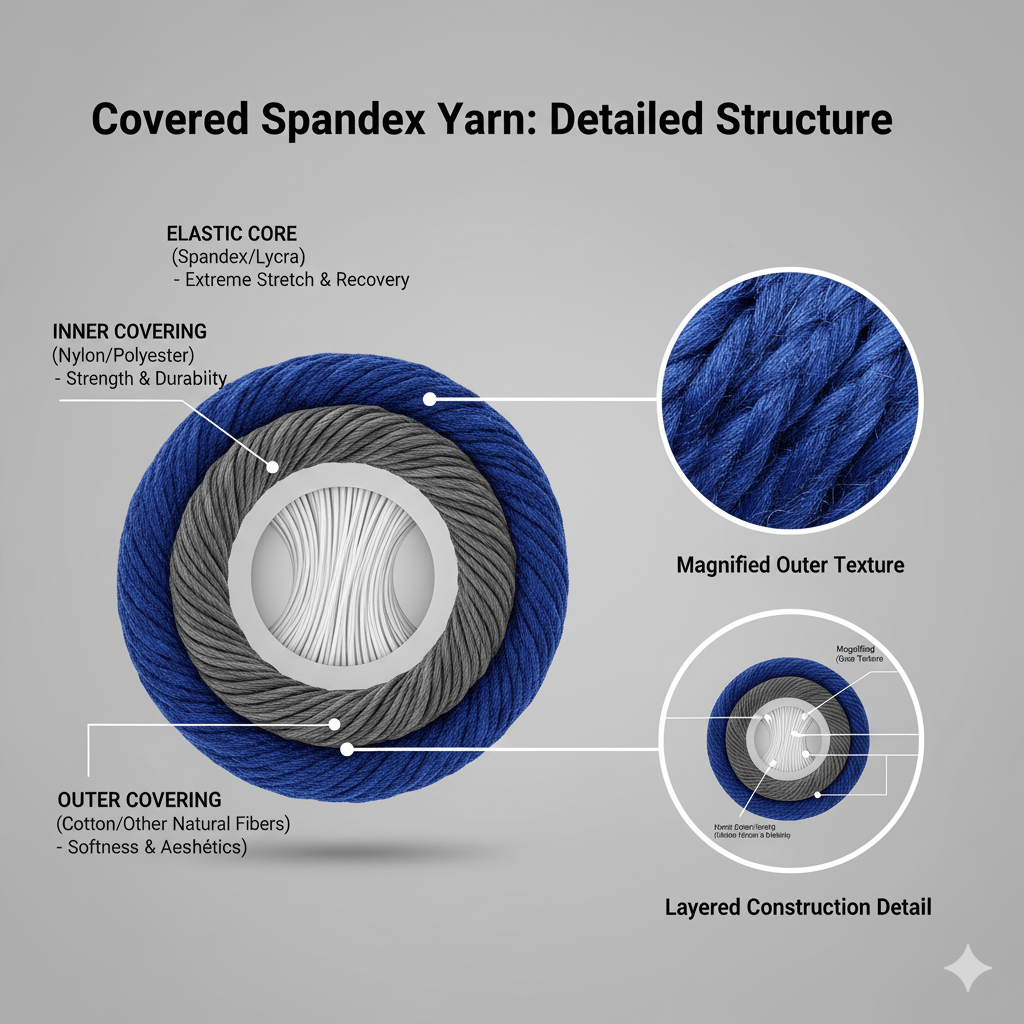

The production of covered elastic yarn involves a sophisticated process where an elastic core is encased within outer textile fibers. The elastic core, typically made from materials like spandex or rubber, provides the necessary stretch and recovery properties. This core is then precision-wrapped with covering fibers, usually synthetic or natural materials, using specialized machinery that maintains consistent tension and coverage.

The selection of covering fibers plays a crucial role in determining the final properties of the yarn. Cotton, polyester, nylon, and other textile fibers are carefully chosen based on the intended application. The covering process can be single or double, with each layer contributing to the yarn’s performance characteristics.

The manufacturing process requires careful control of various parameters, including covering tension, spindle speed, and yarn feed rate. These factors directly influence the quality and properties of the final product, making the manufacturing process both an art and a science.

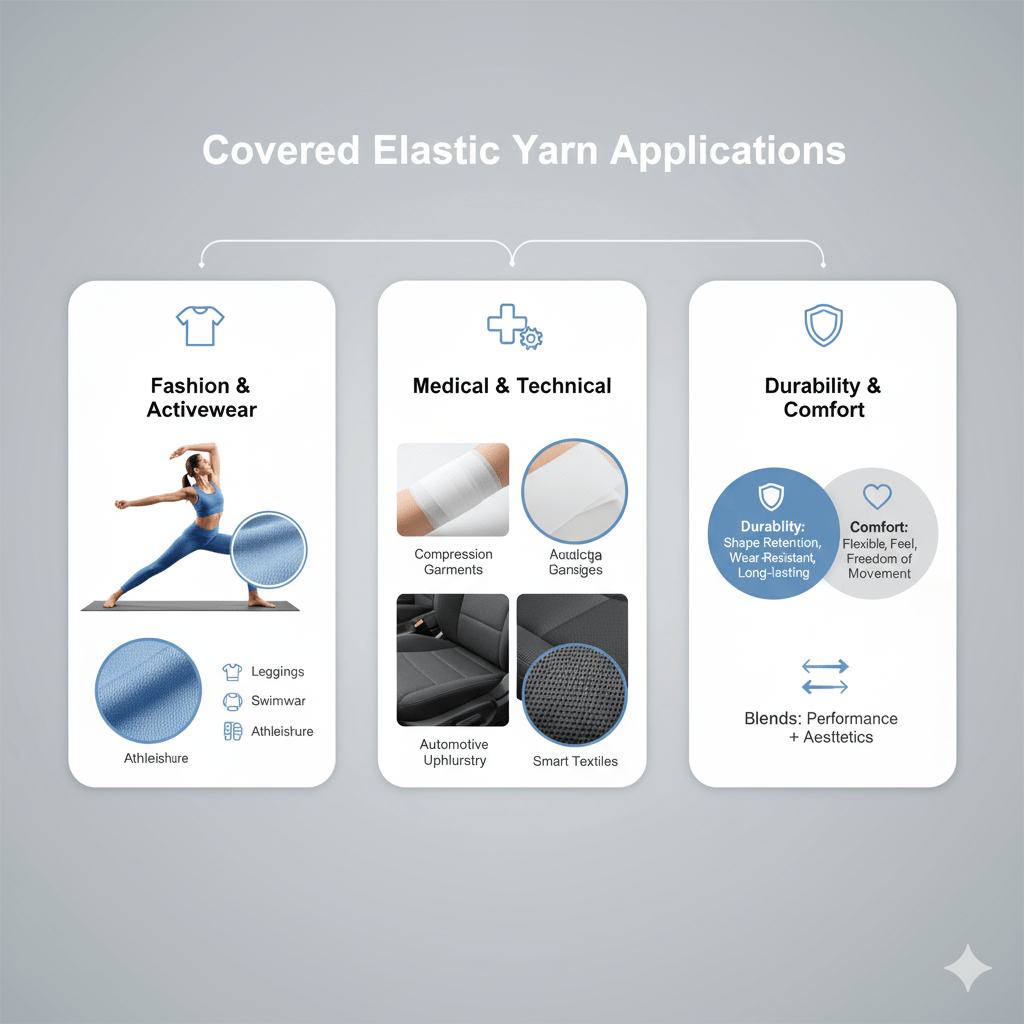

Applications in Fashion Industry

Within the fashion sector, covered elastic yarn has become indispensable for creating comfortable, form-fitting garments. High-end athletic wear relies heavily on this technology to provide compression and support while maintaining aesthetic appeal. The fashion industry has embraced covered elastic yarn for its ability to create silhouettes that combine style with comfort.

Design houses utilize different variations of covered elastic yarn to achieve specific effects in their collections. From subtle stretch in formal wear to high-performance sportswear, the versatility of this material has opened new possibilities in garment design and construction. The ability to maintain shape after repeated use makes it particularly valuable in premium clothing applications.

The integration of covered elastic yarn in fashion has also led to innovations in sustainable and eco-friendly clothing options. Manufacturers are exploring biodegradable covering materials and recycled elastic cores to meet growing environmental concerns while maintaining performance standards.

Technical Textiles and Industrial Uses

Beyond fashion, covered elastic yarn finds extensive application in technical textiles and industrial applications. Medical textiles, including compression garments and bandages, rely on the controlled stretch and recovery properties of these yarns. The ability to maintain consistent pressure while allowing breathability makes them ideal for therapeutic applications.

Industrial applications extend to automotive textiles, where covered elastic yarn is used in seat covers and interior components. The durability and resistance to environmental factors make it suitable for demanding applications. In aerospace and military textiles, specialized versions of covered elastic yarn meet strict performance requirements while providing necessary flexibility and protection.

The development of smart textiles has opened new frontiers for covered elastic yarn applications. Integration with conductive materials and sensors has led to innovations in wearable technology and monitoring systems, showcasing the material’s adaptability to emerging technologies.

Advantages of Covered Elastic Yarn

The primary allure of covered elastic yarn lies in its remarkable blend of properties that cater to a myriad of needs across different industries. Its stretchability ensures garments fit snugly, enhancing comfort without compromising movement. This feature is paramount in sectors like sportswear, where freedom of motion and support play vital roles.

Moreover, covered elastic yarn provides superior recovery capabilities—once released from tension, it returns to its original shape seamlessly. This resilience contributes not only to prolonged garment life but also enhances the overall wear experience. Users often speak of garments made with this yarn feeling more like a second skin, boosting confidence while engaging in physical activities or simply going about daily lives.

In terms of aesthetic quality, covered elastic yarn can be designed with various colors, textures, and patterns through the choice of covering fibers. Consumers are increasingly drawn to apparel that combines performance with visual appeal, giving fashion designers a considerable edge when exploring new collections and trends.

Covered spandex yarn

Delving into the world of covered spandex yarn reveals its unique characteristics and applications. As a specific type of covered elastic yarn, covered spandex offers unparalleled stretch and durability, becoming a favorite among both consumers and manufacturers alike. Its adaptability has allowed it to become an essential component in garments that demand elasticity without sacrificing style or function.

Unique Composition and Benefits

Covered spandex yarn typically features a core of spandex, which is renowned for its exceptional elasticity. The spandex is enveloped in durable fibers such as nylon or polyester, lending both strength and visual appeal to the final product. This blend results in a fabric that returns to form unscathed after being stretched, making it ideal for body-hugging clothing like leggings and swimwear.

The benefits extend beyond mere performance; covered spandex yarn lends itself well to moisture-wicking and temperature-regulating fabrics. Many brands have capitalized on these attributes, designing clothes that not only look good but actively enhance comfort during physical activity. The ability to keep cool and dry significantly elevates user experience, reinforcing loyalty towards brands that prioritize functional fabrics.

Furthermore, the tight weave and elastic nature of covered spandex yarn make it resistant to wear and tear. Consumers can enjoy their favorite stretchy garments for longer periods, contributing to sustainable practices by reducing waste associated with fast fashion.

Popular Uses in Activewear

Activewear has seen a meteoric rise in popularity, partially due to the performance capabilities of covered spandex yarn. This material plays an essential role in creating gym attire that meets modern athletes’ demands for flexibility, breathability, and durability. Brands competing in this bustling market leverage covered spandex to deliver products that promise and deliver high performance.

Yoga pants exemplify where covered spandex shines, providing the necessary stretch for poses while maintaining a sleek silhouette. Additionally, these materials are used extensively in running gear, where moisture management and air circulation are critical to enhance performance during long-distance runs.

Notably, the shift toward athleisure—a blend of athletic and leisurewear—has propelled the desire for stylish yet functional clothing. Covered spandex yarn enables designers to create vibrant patterns and trendy silhouettes that seamlessly transition from workouts to casual outings. The growing consumer preference for versatile garments ensures the continued relevance of covered spandex in both activewear and mainstream fashion.

Exploration in Sustainability

With increasing awareness of environmental issues surrounding textile production, the exploration of sustainability in covered spandex yarn has gained traction. Manufacturers are now considering eco-friendly alternatives, including recycled fibers and reduced water usage during production processes. Awareness-raising efforts around sustainable fashion have prompted consumers to seek out responsibly-produced garments, leading brands to adapt accordingly.

This trend opens up a dialogue about the impact of synthetic materials like spandex on the environment. By focusing on reducing plastic waste and embracing circular economy principles, brands using covered spandex yarn can position themselves as leaders in sustainability within the apparel industry. As consumers continue to gravitate toward ethically-sourced products, the potential demand for sustainable covered spandex will likely see substantial growth, shaping future innovations.

Difference between polyester and spandex

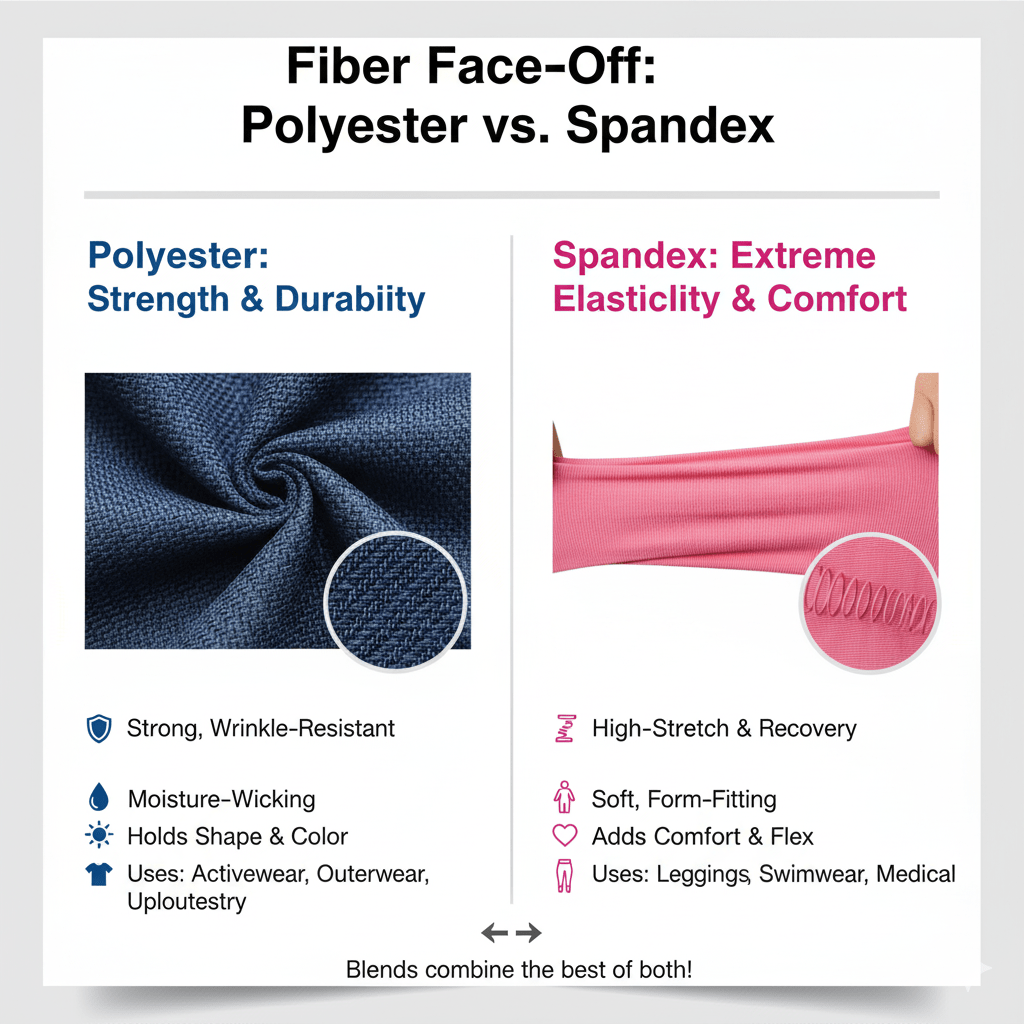

Although both polyester and spandex are commonly used in textiles, their distinct characteristics make them suitable for different applications. Understanding how these materials differ provides valuable insights for consumers, manufacturers, and designers, guiding choices based on intended use.

Properties and Characteristics

Polyester is a synthetic fiber celebrated for its durability, resistance to stretching, and ease of care. It possesses excellent moisture-wicking properties, facilitating the quick evaporation of sweat, which can be advantageous in various climates. Additionally, polyester maintains stability and retains color well, giving it a long-lasting appearance even after numerous washes.

In contrast, spandex, often known by brand names like Lycra, is primarily valued for its exceptional elasticity. It can stretch multiple times its original length while retaining its shape, making it particularly effective in garments that require significant movement like leggings or fitted dresses. However, spandex often requires a supportive fiber to maintain structure, establishing a common pairing with polyester.

While polyester focuses on durability, moisture management, and structural integrity, spandex looks to ensure maximal stretch and recovery. The fundamental differences in their properties dictate the combinations used to tackle specific design challenges in diverse textile applications.

Suitable Applications

Each fiber finds its niche in the textile landscape. Polyester is widely used in manufacturing shirts, outdoor gear, upholstery, and curtains, thanks to its resilience and easy maintenance. Individuals are often drawn to polyester garments for everyday wear because they preserve shape and color over time, requiring less upkeep than natural fibers like cotton.

Conversely, spandex specializes in specialized apparel like swimsuits, activewear, and shape-enhancing garments. Its stretching abilities support high-impact activities, allowing for freedom of movement without fear of garment failure. For users who prioritize comfort and functionality during workouts, spandex-rich combinations provide the most optimal experience.

As fashion trends continue to move toward versatility, hybrid fabrics combining polyester and spandex have emerged. This fusion offers the best of both worlds: durability combined with stretchiness, enabling pleasant wear experiences without compromising aesthetics. These blends frequently appear in athleisure lines, catering to people looking for stylish yet breathable clothing options.

Maintenance and Care

Maintaining polyester and spandex fabrics varies slightly, which could influence consumer choices based on lifestyle. Polyester fabric is relatively low-maintenance, and often washed and dried easily, making it suitable for busy individuals seeking convenience in care routines.

Spandex, on the other hand, may require more delicate treatment. While it retains shape remarkably well, excess heat from high-temperature washing or drying can damage its elasticity over time. Common advice involves washing these garments in cold water and avoiding heavy detergent concentrations to protect the textile structure.

Consumers should balance practicality and care when selecting garments, keeping in mind the differences in maintenance to maximize the longevity of their attire.

Is polyester and spandex a good material

When examining whether polyester and spandex are good materials, one cannot ignore the multifaceted advantages they bring to various applications. Both fabrics have established a firm foothold in the textile industry, appealing to a diverse audience spanning casual and performance-based needs.

Versatile Functionality

One of the standout qualities of materials like polyester and spandex is their inherent versatility. Whether for casual wear or high-impact athletic attire, these fibers can be engineered to meet specific functional requirements.

The blend of polyester’s durability with spandex’s stretch creates formidable fabrics ideal for multi-functional wardrobes. These textiles adapt well to various weather conditions and activities, from summer’s swelter to winter’s chill. Athleisure, which emphasizes comfort while staying fashionable, has thrived thanks to these adaptable materials that harmoniously combine practical functionality with aesthetic value.

This versatility extends into specialized cycling gear, swimwear, and even sleepwear. Collectively, consumers appreciate materials that offer seamless transitions between activities while prioritizing comfort and usability. In a world where multitasking reigns supreme, garments made from these fibers cater to the demanding lifestyle of the modern individual.

Comfort and Aesthetic Appeal

The comfort level provided by blended polyester and spandex garments resonates with consumers. Soft to the touch, lightweight, and breathable, these fabrics facilitate ease of movement, inherently improving wearers’ experiences. Gone are the days of stiff, restrictive garments; modern offerings focus on ultimate comfort alongside visual appeal.

Fashion designers leverage the striking properties of these textiles to produce clothing that flatters without holding the wearer back. With the rise of inclusive sizing, brands explore how these materials emphasize form while delivering flattering designs. The narrative shifts from just merely wearing something functional to embracing pieces that evoke confidence and self-expression.

Elevating comfort and aesthetics has become crucial, allowing consumers to embrace their individuality while enjoying functional benefits. As fashion continues to evolve, the combination of polyester and spandex exists at the intersection of beauty and utility.

Ecological Considerations

Despite their numerous advantages, environmental concerns regarding synthetic fibers cannot be overlooked. The production and disposal of polyester and spandex raise questions about sustainability and ecological responsibility.

However, advances are occurring rapidly in developing eco-friendlier alternatives, including recycled polyester and sustainable production practices. Textile companies are consciously addressing the implications of their materials, driving intentional conversations about environmental stewardship. This aligns well with shifting consumer attitudes that prioritize sustainability.

As a response, consumers now seek brands that transparently communicate eco-consciousness. Choosing polyester and spandex from responsible sources positions consumers as informed participants in modern fashion narratives—and, in turn, adds to the burgeoning sustainability discourse.

Conclusion

The impressive attributes of covered elastic yarn, covered spandex yarn, polyester, and spandex reflect an evolution in textile technology that facilitates a diverse array of applications ranging from high-fashion essentials to resilient technical textiles. Each type of material holds its own set of advantages, paving the way for innovations that promise to redefine wearing experiences. As industries strive to integrate sustainable practices into material selection, textile technology will continue reshaping future garments, ensuring they balance performance, style, and environmental consciousness in our ever-evolving wardrobe demands.