In the specialized field of elastic textiles, Covered Spandex Yarn represents the most sophisticated category within the broader “covered elastic yarn” family. While the term “covered elastic yarn” encompasses various elastic cores including natural rubber, Covered Spandex Yarn specifically utilizes synthetic spandex filaments as its core, delivering superior elasticity, finer deniers, and enhanced durability. This technical deep dive explores why Covered Spandex Yarn has become the preferred choice for high-performance applications across fashion, sportswear, and medical textiles.

Understanding Covered Spandex Yarn Fundamentals

Definition & Structure

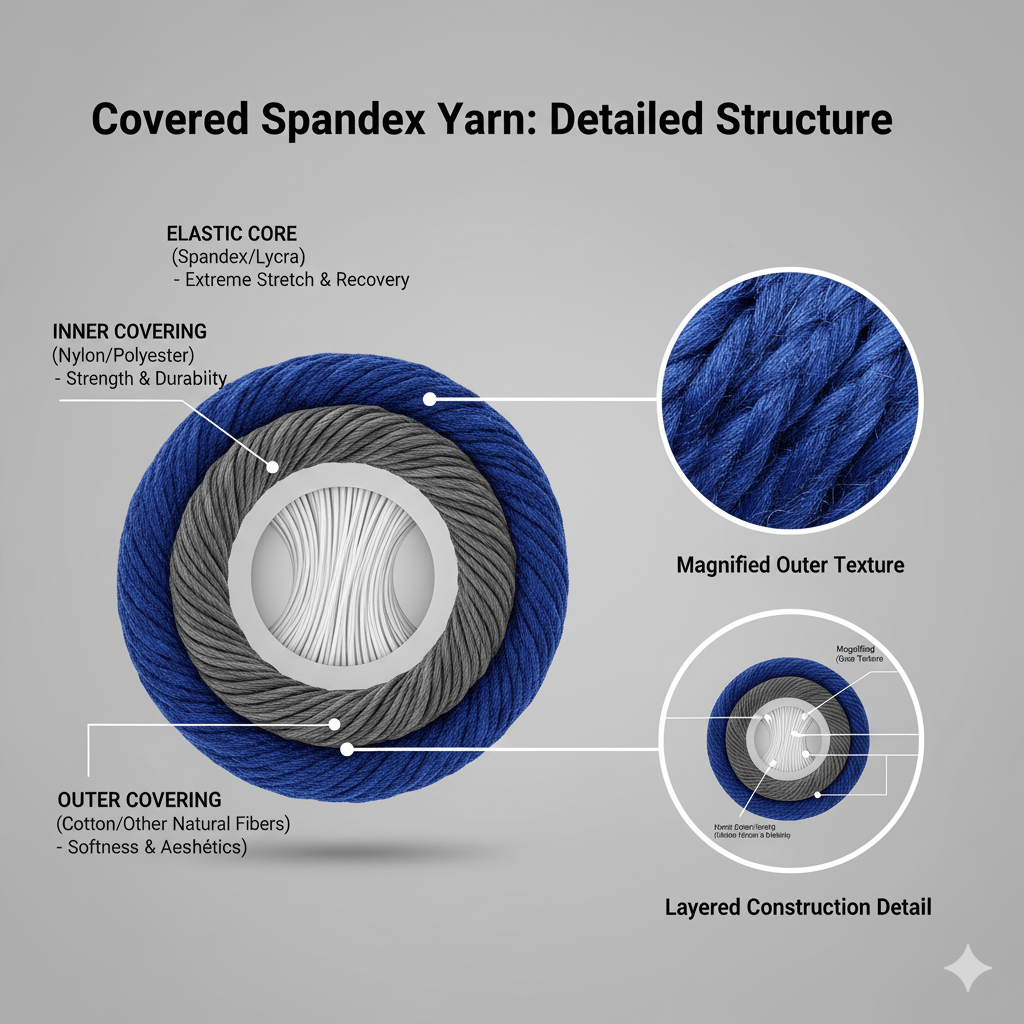

Covered Spandex Yarn is an engineered composite yarn featuring a spandex filament core that’s helically wrapped with one or more layers of non-elastic yarn. The covering materials—commonly cotton, polyester, nylon, or rayon—serve multiple critical functions: they protect the delicate spandex core during weaving and knitting processes, provide enhanced processing capabilities, and deliver specific surface characteristics to the final fabric.

It’s crucial to distinguish between “covered yarn” and “core-spun yarn”—while both contain a central core, covered yarn involves wrapping existing yarns around the core, whereas core-spun integrates the covering during the initial spinning process.

Types & Covering Methods: A Detailed Analysis

The manufacturing of Covered Spandex Yarn involves several critical configurations and methods that significantly impact the final product’s performance and application suitability.

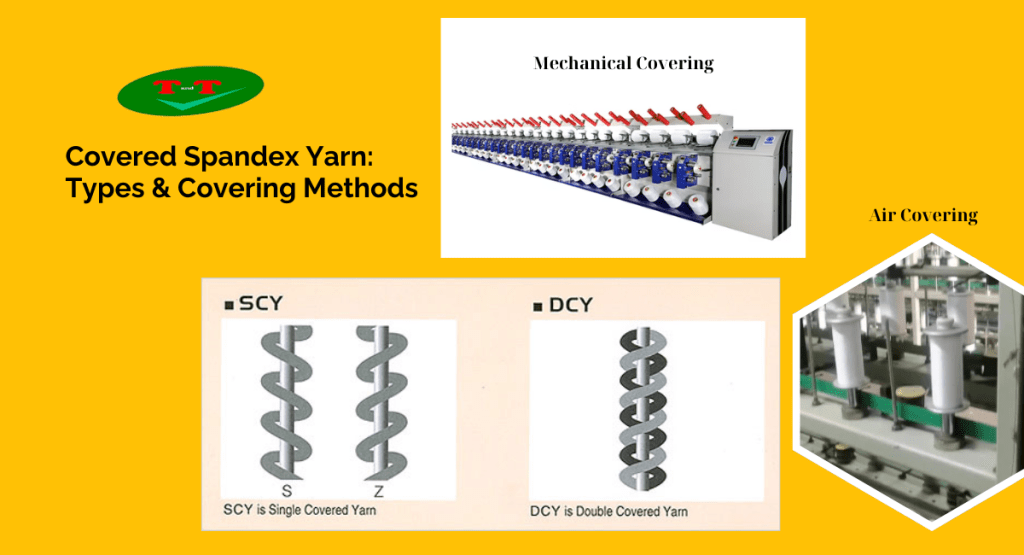

Configuration Types:

- Single Covered Yarn: Features one layer of wrapping yarn, typically used in lightweight applications where maximum stretch and minimal bulk are desired. This configuration offers excellent elasticity while maintaining a soft hand-feel, making it ideal for intimate apparel and lightweight sportswear.

- Double Covered Yarn: Incorporates two layers wrapped in opposite directions, providing enhanced spandex protection and superior opacity. This construction significantly reduces “grin-through” (where the spandex becomes visible when stretched) and offers better tension control during manufacturing. Double covered variants are essential for heavy-duty applications like compression garments and high-quality waistbands.

Covering Methodologies:

- Mechanical Covering: Utilizes precision machinery to create dense, compact yarns with excellent tensile strength. This method produces yarns with consistent wrapping tension, making them suitable for applications requiring dimensional stability and durability, such as automotive textiles and technical fabrics.

- Air Covering: Employs air-jet technology to create softer, bulkier yarns with enhanced coverage. This method produces yarns with superior softness and comfort, perfect for premium activewear and intimate apparel where next-to-skin comfort is paramount.

The selection between single or double covering and mechanical versus air covering depends entirely on the end-use requirements, balancing factors of comfort, durability, processing efficiency, and cost-effectiveness.

Why Covered Spandex Yarn is Revolutionizing Modern Textiles

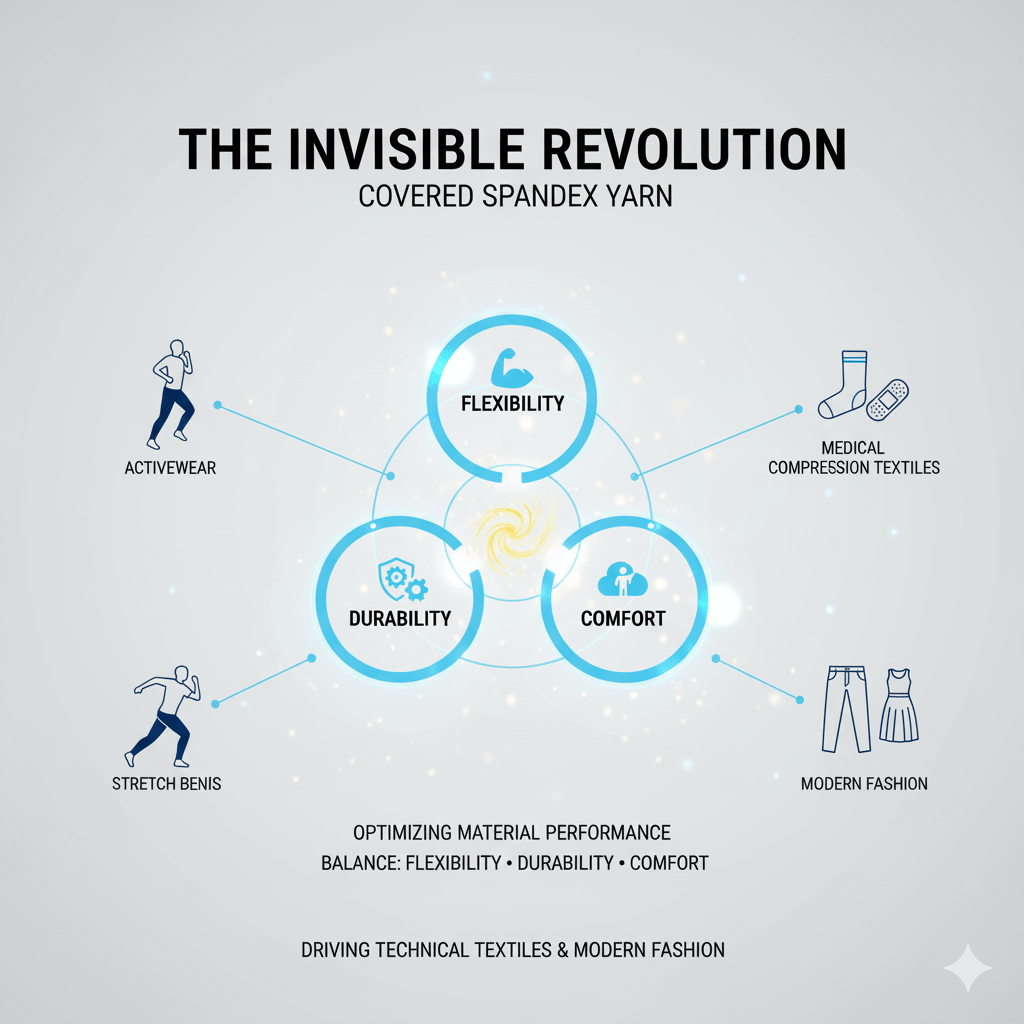

Covered Spandex Yarn is an invisible revolution because it optimizes material performance, providing a perfect balance between Flexibility, Durability, and Comfort, thereby continuously driving the development of technical textiles and modern fashion.

- Enhancing Fabric Performance: Covered Spandex Yarn delivers exceptional elasticity with reliable recovery, enabling fabrics to maintain their original shape through repeated stretching and washing cycles. The strategic combination of spandex core with robust covering materials significantly improves abrasion resistance and overall durability compared to bare spandex or alternative elastic yarns. This enhanced performance translates to longer-lasting garments that maintain their fit and functionality over time.

- Versatility in Applications: The adaptability of Covered Spandex Yarn spans multiple industries and product categories. In fashion and activewear, it enables the creation of body-hugging silhouettes that move with the wearer, from yoga pants that maintain their compression to athletic tops that provide unrestricted movement. The medical sector relies on its consistent performance for compression garments that deliver therapeutic pressure levels, while the intimate apparel industry values its gentle elasticity and soft hand-feel. Even traditional woven fabrics like denim have been transformed through incorporation of covered spandex, allowing for stylish designs that don’t compromise on comfort.

- Visual & Hand-feel Advantages: The covering process creates significantly smoother fabric surfaces, completely eliminating the unsightly “grin-through” effect common with uncovered spandex. This results in premium-looking textiles that maintain their aesthetic appeal even under tension. Furthermore, manufacturers can select covering materials that impart specific tactile properties—from the soft warmth of cotton to the sleek coolness of nylon—while preserving the functional benefits of elasticity.

Manufacturing Process Insights for Covered Spandex Yarn

The production of high-quality Covered Spandex Yarn demands meticulous attention to several critical stages. The process begins with precise spandex pre-drawing, where the spandex filament is stretched to specific ratios (typically between 2.5-4.0x) to activate its elastic properties and ensure consistent performance. This crucial step determines the yarn’s ultimate elongation characteristics and recovery power.

Following pre-drawing, the covering phase requires exacting tension control throughout the wrapping process. Maintaining consistent wrapping tension is paramount for achieving uniform yarn diameter and preventing issues like barre marks in the final fabric. Modern covering machines incorporate sophisticated tension monitoring systems that automatically adjust to maintain optimal conditions, ensuring every meter of yarn meets strict quality standards.

Twist optimization represents another vital manufacturing consideration. The twists per meter (TPM) must be carefully calibrated to balance covering completeness with elasticity preservation. Excessive twist can constrain the spandex core and reduce stretch capability, while insufficient twist may result in inadequate coverage and potential spandex exposure. Manufacturers must fine-tune this parameter based on the specific covering materials and end-use requirements.

Market Trends & Innovations in Covered Spandex Yarn

The Covered Spandex Yarn market is experiencing dynamic evolution driven by changing consumer demands and technological advancements. Sustainability has emerged as a dominant trend, with manufacturers increasingly developing eco-friendly variants utilizing recycled PET and bio-degradable spandex alternatives. These innovations respond to growing environmental consciousness among both brands and consumers.

Performance enhancement continues to be a key innovation driver, with developments in moisture-wicking capabilities, thermoregulation, and customized elasticity profiles for specific applications. The market has seen particular growth in specialized yarns for compression therapy, athletic performance, and comfort-focused casual wear. Major global spandex producers like Hyosung, Invista, and Taekwang are investing heavily in research and development to push these boundaries further.

Despite promising growth, the industry faces significant challenges including raw material cost volatility, production complexity management, and increasingly stringent environmental regulations. However, the continued expansion of athleisure and performance apparel markets suggests sustained demand growth for advanced Covered Spandex Yarn solutions that balance performance with sustainability.

Applications & Case Examples of Covered Spandex Yarn

Covered Spandex Yarn has countless real-world applications and examples across various industries, thanks to its perfect balance of elasticity, durability, and comfort.

- Sportswear and Activewear: In high-performance athletic wear, Covered Spandex Yarn enables unprecedented freedom of movement and shape retention. For instance, in premium yoga pants, double-covered constructions provide the perfect balance of compression and comfort, allowing for full range of motion while maintaining their shape through intense workouts. The covering protects the spandex from sweat and friction, ensuring longevity even with frequent washing.

- Medical Compression Garments: The medical sector relies on precisely engineered Covered Spandex Yarn for therapeutic compression products. Graduated compression stockings for venous disorders utilize covered yarns to deliver consistent pressure gradients crucial for effective treatment. The double-covered construction ensures no direct spandex-skin contact, reducing irritation risk for patients requiring extended wear.

- Fashion and Denim: The denim industry has been revolutionized by Covered Spandex Yarn, which allows for stylish, form-fitting designs without compromising comfort. Modern stretch denim incorporating covered spandex maintains its shape through multiple wears and washes, addressing the traditional compromise between fashion and function. The covered construction prevents the spandex from being exposed to dyeing chemicals, maintaining consistent coloration.

- Intimate Apparel and Hosiery: In intimate apparel, single-covered variants provide the gentle elasticity and softness required for comfort-sensitive applications. Luxury lingerie brands utilize air-covered yarns for their superior hand-feel and seamless integration into delicate fabrics. Similarly, premium hosiery benefits from the consistent tension and smoothness of covered constructions.

Benefits & Considerations of Covered Spandex Yarn

Key Benefits

The primary advantage of Covered Spandex Yarn lies in its superior stretch recovery compared to alternative elastic yarns. The protected spandex core maintains its elasticity longer, ensuring garments keep their shape throughout their lifespan. Enhanced durability is another significant benefit, as the covering yarn shields the delicate spandex from abrasion, chemicals, and mechanical stress during manufacturing and use.

Manufacturing compatibility represents a crucial practical benefit, as covered yarns can be processed on conventional knitting and weaving machinery without special modifications. This versatility extends across multiple fabric types, from fine gauges for hosiery to heavy constructions for upholstery. The excellent surface aesthetics achieved through proper covering eliminate common visual defects associated with bare spandex, resulting in premium-looking textiles.

Important Considerations

The production complexity of Covered Spandex Yarn inevitably leads to higher costs compared to simple blended yarns. Manufacturers must carefully evaluate whether the performance benefits justify the additional expense for their specific application. Proper selection between single and double covering is essential, as under-specifying can lead to performance issues while over-specifying increases costs unnecessarily.

Environmental considerations are becoming increasingly important, as recycling spandex blends presents significant challenges. Brands committed to circularity must develop strategies for end-of-life management of products containing Covered Spandex Yarn. Quality control remains paramount, as variations in covering evenness, tension consistency, or spandex quality can dramatically affect final product performance.

How to Select the Right Covered Spandex Yarn

Selecting the appropriate Covered Spandex Yarn requires systematic evaluation of multiple factors to ensure optimal performance in the final application. Begin by thoroughly analyzing the end-use requirements, considering factors like stretch percentage, recovery force, durability expectations, and comfort needs. Lightweight applications like sheer hosiery demand different specifications than heavy-duty uses such as automotive textiles.

The choice between cover types and methods should align with both performance requirements and production capabilities. Single covering suffices for most standard applications, while double covering becomes necessary for high-stress environments or when maximum opacity is required. Similarly, mechanical covering suits applications prioritizing strength and stability, while air covering better serves comfort-focused products.

Technical specifications demand careful scrutiny, with particular attention to denier/tex measurements, spandex percentage content, twist levels, and uniformity metrics. Reputable suppliers should provide comprehensive test reports validating these parameters. Certification compliance, such as Oeko-Tex Standard 100 for harmful substances, becomes crucial for products with skin contact.

Supplier selection ultimately determines success, as consistent quality requires manufacturing expertise and robust quality systems. Partner with established manufacturers demonstrating technical capability, production consistency, and responsive customer support. Request samples for thorough testing under conditions simulating actual use before committing to volume orders.

Conclusion: The Strategic Importance of Covered Spandex Yarn

Covered Spandex Yarn has established itself as a fundamental component in modern textile manufacturing, enabling the creation of innovative products that seamlessly blend comfort, performance, and durability. Its versatile applications span from life-changing medical devices to fashion-forward activewear, demonstrating its critical role across multiple industries. As textile technologies advance, Covered Spandex Yarn continues to evolve, incorporating sustainable materials and enhanced functionalities to meet changing market demands.

For businesses seeking to leverage these advancements, choosing the right manufacturing partner is crucial for success. Our company has built its reputation on consistent quality, technical expertise, and reliable partnership—exactly the foundation needed for long-term textile innovation. We understand that your success depends on predictable performance and supply chain stability, which is why we’ve invested in advanced manufacturing technologies and rigorous quality control systems.

Ready to explore how Covered Spandex Yarn can enhance your textile products? Contact our technical team today for personalized consultation and sample requests. Let’s discuss your specific requirements and develop solutions that drive your product innovation forward.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com