Covered spandex yarn has gained significant popularity in various sectors, particularly in the textile and fashion industries. This yarn combines both flexibility and strength, making it suitable for an array of applications from athletic wear to everyday clothing. The production of covered spandex yarn is a fascinating aspect of textile engineering, showcasing advances in material science and manufacturing techniques.

Covered spandex yarn

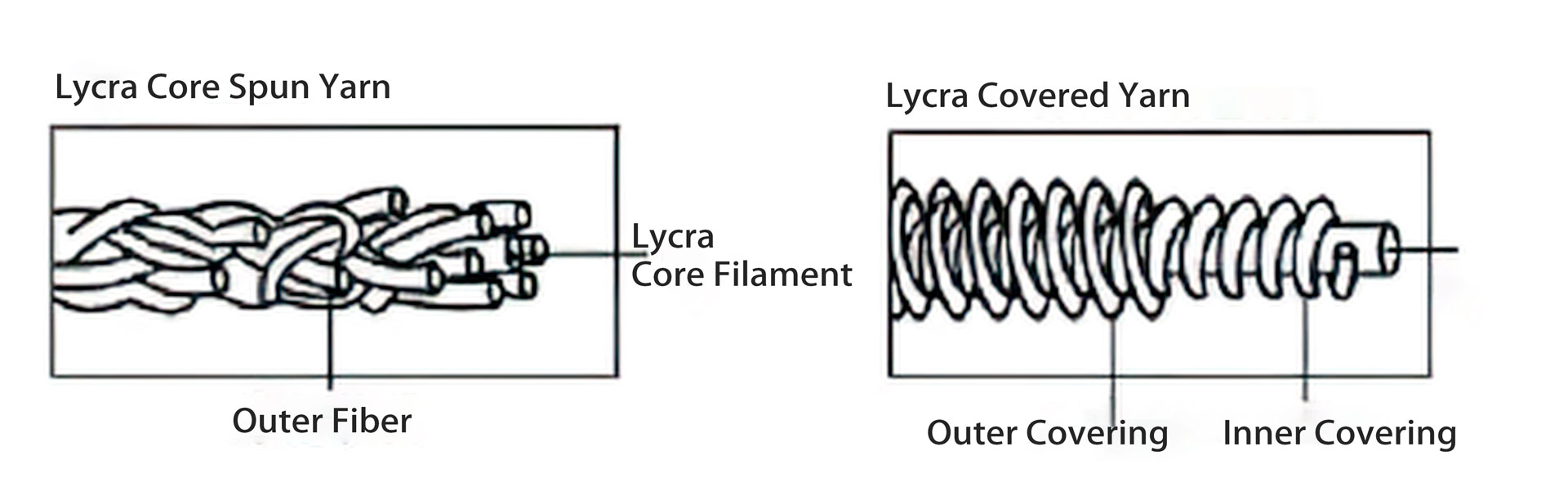

Covered spandex yarn is a unique textile material characterized by its elastic properties and versatility. It is essentially a core-spun yarn, where strands of spandex are wrapped with another fiber, usually cotton, nylon, or polyester. This combination not only enhances the elasticity of the yarn but also protects the spandex, giving it durability and a softer touch.

The history of covered spandex yarn production can be traced back to the mid-20th century when the demand for elastic and stretchable fabrics began to surge. As athletic wear became more normalized in everyday fashion and performance gear, textile manufacturers recognized the necessity for materials that would provide both comfort and flexibility.

The process of creating covered spandex yarn involves intricate spinning techniques, where the core of spandex is completely enveloped by another fiber. This enables the fabric to maintain its shape while offering unparalleled stretchability. The flexibility of covered spandex yarn means it can also be designed into various weights and thicknesses, catering to different textile needs.

One of the most remarkable aspects of covered spandex yarn is its adaptability across various sectors. It’s used widely in creating activewear, swimwear, lingerie, and undergarments, making it a staple in clothing production. Moreover, its incorporation into fabrics has transformed the clothing industry, allowing for designs that can stretch with the wearer while retaining their structural integrity.

Manufacturing Process

The manufacturing process of covered spandex yarn is intricate and requires a high level of precision. The initial stage involves selecting the right quality of spandex for the core. Typically, the spandex is manufactured under controlled conditions to ensure optimal elasticity and performance.

Once the core spandex is prepared, the wrapping process begins. Fibers such as cotton, polyester, or nylon are spun around the spandex core using high-speed machines. The choice of outer fiber affects the ultimate texture and performance characteristics of the yarn.

After the yarn has been spun, it undergoes rigorous testing to assess its elasticity, strength, and overall quality. These quality control measures are vital to ensure that the yarn meets industry standards and consumer expectations.

Applications and Markets

Covered spandex yarn finds applications in a wide range of markets. One of the most significant markets is the athletic wear sector, where breathability and stretchability are paramount. Gym clothes, yoga pants, and sports uniforms heavily rely on the flexibility provided by such yarn.

Another market where covered spandex yarn makes a substantial impact is in the lingerie and undergarment industry. The smooth texture and stretchability allow for comfortable wear, which is crucial for these garments. This adaptability fosters creativity in design, enabling manufacturers to produce garments that fit comfortably while offering the required support.

The swimwear industry also extensively uses covered spandex yarn due to its moisture-wicking properties and resistance to chlorine damage. This versatility of application contributes to the ongoing demand for covered spandex yarn, making it a key player in the world of textiles.

Spandex covered yarn hs code

The Harmonized System codes play a vital role in international trade, providing a standardized numerical method of classifying goods. For spandex covered yarn, identifying the correct HS code ensures the proper documentation and avoidance of tariffs or delays during shipping and customs processes.

Understanding the HS code for spandex covered yarn involves an exploration of the broader category of textiles and yarns. Generally, yarns that possess elastic properties fall under a specific classification within the textile industry. The HS code system is updated regularly, so industry players must remain informed to ensure compliance.

Regulatory and legal ramifications underscore the importance of identifying the correct HS code. Importers and exporters who fail to classify their products accurately may face penalties or even confiscation of goods. Hence, the identification of the HS code for spandex covered yarn guides businesses in optimizing their supply chain.

Significance of HS Codes

HS codes serve numerous benefits in the textile industry. Primarily, they streamline customs procedures, enabling efficient global trade. Correct classification also aids in the determination of applicable duties and tariffs, influencing pricing strategies for manufacturers and retailers.

Moreover, accurate HS coding contributes to the flow of data regarding international trade trends. This information can drive business decisions and strategic planning in product development and marketing efforts. With the market dynamics continually evolving, this data allows manufacturers to adapt to changing customer preferences.

Impact on Trade

The inclusion of spandex covered yarn under a specific HS code impacts global trade dynamics. The unique properties of spandex covered yarn create demand, helping manufacturers penetrate diverse markets. This demand drives supply chains, facilitating relationships between producers and international retailers.

Furthermore, understanding these codes aids organizations in anticipating regulatory changes that might affect trade. Economic shifts, international trade agreements, and changes in tariffs can all influence the movement of covered spandex yarn across borders.

Covered elastic yarn

Covered elastic yarn is another essential element in the textile production chain, closely related to covered spandex yarn but with some distinct characteristics. This yarn also consists of a core fiber, typically elastic like spandex, wrapped in another fiber that provides texture and strength.

The primary difference lies in the intended use and blend of materials. While covered spandex yarn may exclusively use spandex as its core, covered elastic yarn can utilize other elastic materials, providing variability in functionality and performance.

The productionThe production of covered elastic yarn is similarly intricate, where high-speed machinery is employed to spin and wrap fibers around the core. This ensures that the resulting product maintains elasticity while achieving a desirable texture for various applications in garment making.

Characteristics and Properties

The characteristics of covered elastic yarn make it ideal for multiple uses across different textile sectors. The defining property is its strength, which allows garments to stretch and return to their original shape without losing integrity. Whether used in athletic wear or everyday clothing items, this versatility contributes to comfort, fit, and style.

Additionally, the outer fiber can be chosen based on how the end product should feel against the skin or appear visually. Common fibers such as cotton or nylon are often utilized, each providing unique benefits like breathability, softness, or moisture-wicking properties.

Importantly, the choice of covering fiber directly impacts the performance of the finished fabric in terms of durability and aesthetic appeal. Manufacturers often tailor these yarns to enhance their functionality according to market demands, leading to creative innovations in fashion.

Applications in Fashion and Beyond

Covered elastic yarn finds significant application in the fashion industry, particularly in activewear, undergarments, and swimwear. Athletic brands specifically capitalize on the flexibility and fit offered by this yarn, pushing boundaries in design to enhance user experience during activities.

In fashion, the presence of covered elastic yarn has been transformative. Garments offering better movement have become increasingly popular, catering to consumer needs for comfort without compromising style. From leggings to fitted dresses, its adaptability opens up possibilities for designers aiming to innovate without limit.

Beyond fashion, industries such as automotive textiles and upholstery also utilize covered elastic yarn. It provides the resilience needed in environments subjected to frequent stretching and pulling, underscoring its significance beyond mere clothing.

Air covered spandex yarn

Emerging from advancements in yarn technology, air covered spandex yarn offers a lightweight alternative that retains the excellent stretching properties expected from traditional spandex blends. Utilizing an air-jet process, this method wraps the spandex core in high-bulk synthetic fibers, creating a soft yet durable material.

Air covering involves ”blowing” fibers around the spandex core using pneumatic jets. This method results in a yarn that has additional loft and volume while maintaining breathability. The resultant product enhances comfort without adding excessive weight, providing excellent alternatives for many fabrics.

Benefits and Advantages

The primary advantage of air covered spandex yarn is its ability to maintain low density while delivering substantial elasticity. It presents an excellent option for activewear where athletes require products that don’t weigh them down but still provide maximum stretch!

Moreover, the enhanced breathability means that garments produced with this yarn perform exceptionally well in moisture management, making it ideal for sports and recreational apparel. This characteristic allows sweat to evaporate quickly, keeping wearers dry and comfortable even during intense physical activity.

Another significant benefit of such yarn lies in its visual and tactile qualities. Designers appreciate the unique fullness it brings to fabrics, enabling more voluminous silhouettes without sacrificing functionality. The resulting soft and plush textures create garments that align with modern trends toward comfort-oriented fashion.

Market Trends and Innovations

As consumers increasingly prioritize comfort and performance from their clothes, the demand for air covered spandex yarn continues to rise. This trend aligns with a broader shift toward athleisure – a fusion of athletic and leisurewear that’s become a staple in contemporary fashion.

Innovations in manufacturing techniques and raw materials also propel interest forward. Enhanced sustainability practices, including eco-friendly fibers and processes, serve to attract environmentally-minded consumers seeking comfortable options. This evolving paradigm invites manufacturers to experiment with new color offerings and patterns, showcasing creativity alongside function.

In conclusion, the journey of air covered spandex yarn holds promise not only through current industry practices but also through the visionary direction of future innovations that redefine how we perceive and wear textiles.

What is spandex yarn

Diving deeper into the understanding of spandex yarn, we uncover a synthetic fiber that has significantly changed the fabric landscape since its invention. Spandex, known for its exceptional elasticity, allows materials to stretch up to five times their original length while maintaining their shape.

Spandex is often blended with other fibers to leverage its extraordinary stretchability, bringing dynamic changes to everyday garments. When incorporated into various fabrics, it transforms standard materials into advanced performance textiles, meeting the demands of diverse consumers across the globe.

Unique Attributes of Spandex Yarn

One of the most notable attributes of spandex yarn is its recovery ability. After being stretched, spandex quickly returns to its original shape. This physical property is crucial in garments that undergo regular movement, as they tend to retain their fit over time, favoring long-term consumer satisfaction.

Additionally, spandex exhibits a high degree of comfort, felt through less constrictive wear. Unlike rigid natural fibers, garments made with spandex contour to the body, enhancing mobility and flexibility—traits appreciated in everything from professional attire to casual clothing.

On top of its functional advantages, spandex delivers a luxurious handfeel. It elevates the perception of quality associated with fabrics, which resonates with consumers looking for both comfort and finesse in their wardrobe choices.

Future Directions in Spandex Development

The realm of spandex is one that is continuously evolving, with ongoing research focused on developing sustainable alternatives and enhancing performance features. As eco-consciousness becomes increasingly critical among consumers, manufacturers explore organic and biodegradable spandex options.

Technological enhancements also promote innovations in spandex blends, amplifying not only elasticity but thermoregulation, moisture-wicking, and antimicrobial properties. These developments propel the idea of smart textiles, aligning with modern lifestyles that value efficiency and convenience.

Consequently, the narrative surrounding what spandex yarn represents is shifting from merely a stretchy alternative to a multifaceted material driving change across the fashion landscape.

Spandex yarn price

When considering the spandex yarn price, it’s essential to take various factors into account as prices can fluctuate based on raw material costs, demand, and production processes. Spandex generally remains a valuable input for fabric manufacturing, influencing the overall cost of finished garments.

Market dynamics dictate pricing trends, with global events impacting the availability and cost of materials yielding unexpected shifts. Retailers must remain adept at navigating these fluctuations to promote competitive pricing strategies while ensuring quality standards remain intact.

Factors Influencing Pricing

A primary factor affecting spandex yarn price includes the type and purity of spandex used in production. Higher grades of spandex are typically more expensive due to stricter quality controls and performance guarantees during the manufacturing process.

Additionally, volatility within the petrochemical industry—a significant factor in spandex production—can result in price hikes. Supply chain disruptions or increased demand for synthetic fibers can yield strains that ultimately affect pricing at every level of distribution.

Lastly, trade policies and tariffs imposed on imported materials can alter the economics of purchasing spandex yarn. Companies engaged globally must strategically position their supply chains to ensure reliable access to competitively priced raw materials without sacrificing quality.

Value Perception Among Consumers

Beyond pricing dynamics, the perceived value of spandex yarn also impacts pricing strategies. As brands leverage spandex blends to create high-performance activewear, swimwear, and undergarments, consumers may expect to pay a premium based on quality.

Companies emphasizing transparency regarding material sourcing and ethical production methods can attract consumers willing to invest more in sustainable practices. Consequently, the conversation about pricing transcends numbers and enters the realm of brand loyalty, identity, and responsibility.

Ultimately, understanding the nuances surrounding spandex yarn pricing encapsulates a larger dialogue about quality versus cost, shaping decision-making across segments of the industry.

Difference between polyester and spandex

Both polyester and spandex have carved out influential roles within the textile industry, but understanding the difference between polyester and spandex illuminates why these materials thrive in diverse applications.

Polyester emerges from petroleum-based resources, showcasing exceptional durability, versatility, and resistance to shrinking or wrinkling. Spandex, however, is primarily recognized for its elasticity—designed specifically to stretch, providing unparalleled comfort.

Properties Comparison

The contrast in properties manifests when evaluating garment performance. Polyester fibers exhibit strength, resilience, and moisture-wicking capabilities, rendering them suitable for various applications ranging from sportswear to formal settings. In contrast, spandex enhances fit and stretchability, often acting as a supportive companion within composite fabrics.

While polyester is primarily engineered to be sturdy and resilient, its lack of elasticity means it functions best in conjunction with materials like spandex. Together, these fibers collaborate to create balanced garments, allowing shape retention through movement.

Consumer Perceptions and Use Cases

From a consumer perspective, the difference between polyester and spandex culminates in decisions related to fabric choice and performance expectations. Activewear enthusiasts often seek out blends containing both fibers, resulting in garments that combine the best of both worlds—durability from polyester and stretch from spandex.

Understanding these differences aids manufacturers in selecting appropriate materials according to desired outcomes for the end product. Whether focusing on fashion, athletic wear, or specialized textiles, knowledge of fiber properties informs smarter design solutions.

Ultimately, acknowledging how polyester and spandex interact can illuminate the profound impact of synergy on performance and aesthetics.

Conclusion

In summary, the world of spandex yarn—be it covered spandex yarn, air covered spandex yarn, spandex covered yarn hs code, or covered elastic yarn—is a complex ecosystem rich in innovation and potential. Understanding the intricacies of construction, application, pricing, and cross-fiber relationships provides a comprehensive view of how these materials influence our daily lives.

Spandex stands out due to its unmistakable elasticity and recovery, transforming standard textiles into performance-driven fabrics cherished by consumers across the world. In tandem with other fibers like polyester, spandex enhances garment utility while allowing for imaginative designs and lasting comfort.

The journey ahead for spandex will undoubtedly intertwine advancements in sustainability, technological intricacies, and evolving consumer preferences. To stay relevant in this dynamic landscape, stakeholders within the textile industry must continuously adapt, experimenting with new ideas while valuing the principles that define true quality and craftsmanship.

Support by us