In the vast tapestry of modern textiles, few fibers have woven themselves into the fabric of daily life as completely as elastane. This synthetic marvel, often hiding behind labels for spandex or Lycra®, is the silent architect of the stretch, fit, and freedom we now expect from everything from yoga pants to denim jeans. Its unique ability to stretch up to eight times its original length and snap back to form has revolutionized apparel design, merging performance with everyday comfort.

Yet, for all its ubiquity, elastane remains a material of mystery and misconception. What exactly is elastane fiber? How is it created, and what considerations must we make for its care and environmental footprint?

This definitive guide unravels the science, history, and future of elastane fabric, providing a comprehensive resource for manufacturers, designers, and conscious consumers alike.

Introduction to Elastane Fabric

Definition and Nomenclature

Elastane is a synthetic fiber engineered from long-chain polymers, specifically polyurethane, to deliver extraordinary elasticity. The journey of this fiber from chemical plant to clothing label is accompanied by a variety of names that can confuse consumers and professionals. This nomenclature is largely a matter of geography and branding rather than chemical difference.

In North America, the fiber is almost exclusively called “spandex”, a term born in the labs of DuPont that is, in fact, an anagram of the word “expands”—a fitting tribute to its primary function.

Across the Atlantic, in continental Europe, the generic term “elastane” prevails, aligning with international textile standards (ISO).

Meanwhile, the brand name Lycra®, owned by The Lycra Company (a successor to the original DuPont division), has achieved such market dominance in regions like the UK, Ireland, and Australia that it is often used generically.

Understanding these terms is the first step in decoding garment specifications and global supply chain communications. Regardless of the name, the material’s defining promise remains: to expand with the body and recover without fail.

Origin and History

Elastane’s history began in 1937, when Otto Bayer and his team in Germany developed polyurethane, laying the chemical foundation for future stretch fibers. The real breakthrough came in 1958 at DuPont’s Benger Laboratory, where chemist Joseph Shivers created the first commercially viable elastane. Designed as a superior alternative to rubber—then used in heavy, unstable, and quickly degrading undergarment supports—Shivers’ new fiber (initially called Fiber K, later branded Lycra®) delivered lightweight strength, durability, and exceptional stretch recovery.

Marketed globally in 1962, Lycra® revolutionized clothing. It replaced rigid foundation garments, expanded into swimwear and hosiery, and became indispensable in the athleticwear boom of the 1970s–80s. What began as a solution for uncomfortable shapewear evolved into a transformative fiber that reshaped fashion, sportswear, and modern apparel performance worldwide.

Structure and Manufacturing Process

Chemical Composition

Elastane is a fully synthetic block copolymer, technically classified as a polyether-polyurea. This molecular architecture is the key to its unique properties.

The fiber’s structure consists of alternating “soft” and “hard” polymer segments. The long, flexible polyether chains (soft segments) allow the fiber to stretch extensively, while the rigid urethane linkages (hard segments) act as anchor points, providing the restorative force that ensures the fiber snaps back to its original shape. This synergy—flexibility paired with structured recovery—is the chemical secret to elastane’s unique “memory.” It is a 100% synthetic creation; no organic or natural components are part of its core structure.

Production Method

Several methods exist to produce elastane fiber, including melt extrusion, reaction spinning, and wet spinning. However, solution dry spinning is the dominant industrial process, accounting for approximately 95% of global production due to its efficiency and ability to produce high-quality, fine filaments.

The manufacturing process via solution dry spinning can be broken down into sequential stages:

- Prepolymer Formation: The process begins by reacting a macroglycol (forming the flexible segment) with a diisocyanate monomer in a chemical reactor. This creates an intermediate prepolymer.

- Chain Extension and Solution Preparation: The prepolymer is dissolved in a solvent like dimethylacetamide (DMAC). It then undergoes a chain extension reaction by adding a diamine, which links the molecules into long, stable polymer chains, creating a viscous spinning solution.

- Fiber Spinning (Dry Spinning): The polymer solution is pumped through a spinneret—a plate with microscopic holes—into a vertical spinning cell filled with hot, inert gas. The solvent rapidly evaporates, solidifying the liquid streams into continuous, solid elastane filaments.

- Finishing and Winding: The newly formed filaments are treated with a finishing agent, such as magnesium stearate, to prevent them from sticking together. They are then gathered and wound at high speed onto large spools, resulting in the final bare elastane yarn ready for textile production.

The result is the bare elastane yarn, a bundle of incredibly strong, elastic filaments ready to be covered with nylon, cotton, or polyester and woven into the fabrics that define modern apparel.

Characteristics and Applications in Apparel

Physical Properties

Elastane’s value is derived from a formidable combination of physical properties that natural fibers cannot match, making it an indispensable tool for textile engineers.

- Exceptional Elasticity and Recovery: This is the cornerstone property. Elastane can consistently stretch between 500% to 800% of its original length without breaking. More importantly, its recovery is near-perfect. This “memory” ensures that garments retain their intended shape and fit wash after wash, resisting the bagging and sagging that plague non-elastic fabrics. This recovery is also quantified by its low “hysteresis,” meaning it loses very little energy as heat when stretching and contracting, contributing to its durability.

- Strength and Durability: Despite its delicate appearance, elastane is remarkably strong. It boasts excellent resistance to abrasion and, crucially, to degradation from body oils, sweat, lotions, and repeated washings—weaknesses that rapidly deteriorated its rubber predecessor. This durability ensures the longevity of garments subjected to high stress, like activewear.

- Lightweight and Low Moisture Absorption: Elastane adds critical function without adding weight or bulk. It is inherently hydrophobic, meaning it does not absorb water. In blends, this property can contribute to a fabric’s overall moisture-wicking capability, helping to move perspiration away from the skin to the outer surface of the garment where it can evaporate.

Key Applications

The unique properties of elastane have led to its infiltration into nearly every segment of the apparel industry, always with the goal of enhancing comfort, fit, and performance.

- Activewear and Sportswear: This is perhaps elastane’s most visible domain. In leggings, sports bras, cycling shorts, and athletic tops, elastane provides the four-way stretch necessary for a full range of motion. It also enables compression, which can support muscles, improve circulation, and reduce fatigue during athletic performance.

- Intimate Apparel and Swimwear: For lingerie, shapewear, and swimsuits, elastane delivers the consistent, firm elasticity required for support, control, and a flawless, conforming fit. In swimwear, specific types of elastane are engineered for high chlorine resistance to prevent degradation from pool chemicals.

- Fashion and Denim: The “comfort revolution” in everyday clothing is powered by elastane. Adding just 2-5% to woven fabrics like cotton denim, twill, or suiting transforms them. “Stretch jeans” offer ease of movement and sitting without compromising style, while dresses and skirts gain improved drape and wrinkle resistance.

- Medical Textiles: In healthcare, elastane’s controlled elasticity is therapeutic. It is essential in graduated compression garments for managing lymphedema or post-surgical recovery, as well as in surgical hosiery and braces, where consistent, measurable pressure is required.

- Specialized Technical Uses: Beyond clothing, elastane’s conforming properties make it ideal for motion capture suits used in film and video game production, where it allows sensors to track an actor’s movements accurately without restriction.

Washing and Care Instructions

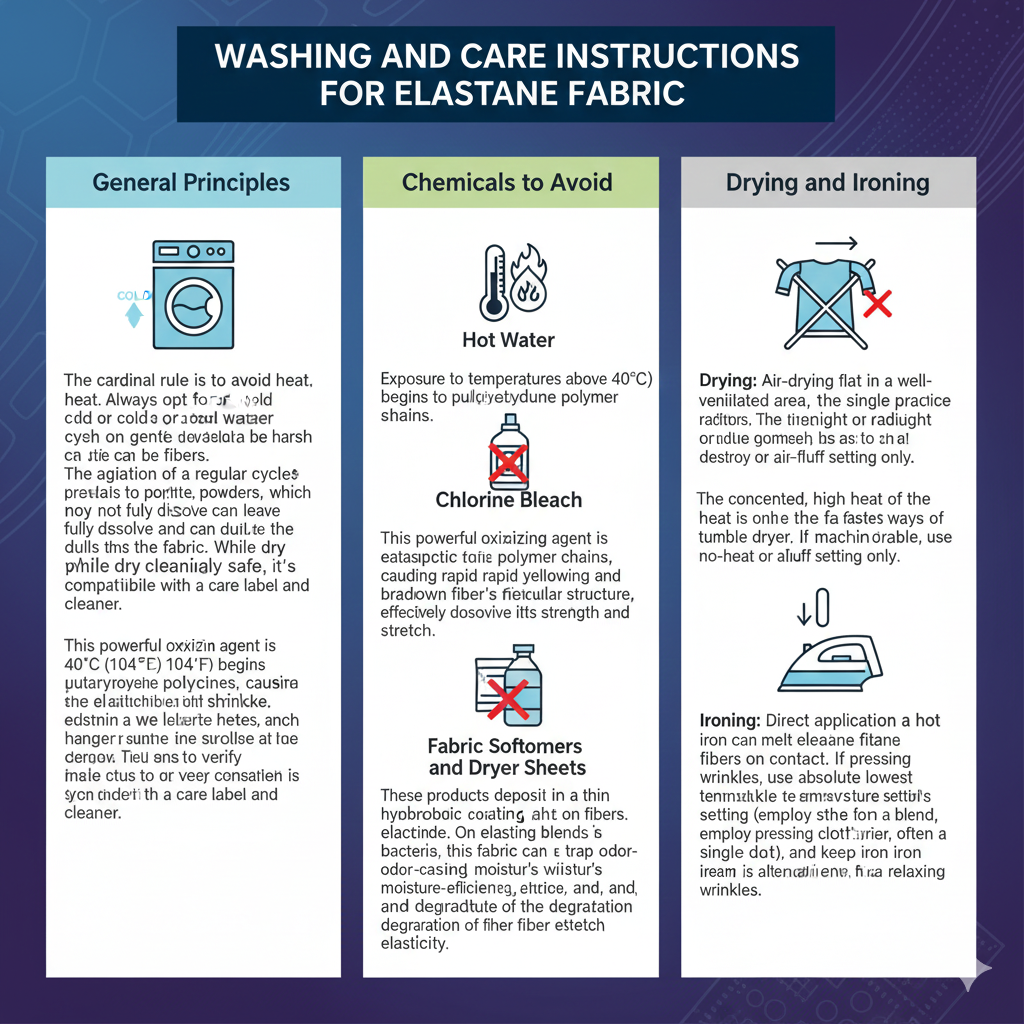

The longevity of any elastane-blended garment hinges entirely on proper care, as the polyurethane fibers are particularly vulnerable to common laundry mistakes.

General Principles

The cardinal rule is to avoid heat. Always opt for a cold or cool water wash on a gentle cycle. The agitation of a regular cycle can be harsh on the fibers. A mild, liquid detergent is preferable to powders, which may not fully dissolve and can leave a residue that dulls the fabric. While dry cleaning is generally safe, it’s prudent to verify compatibility with the care label and cleaner.

Chemicals to Avoid

- Hot Water: Exposure to temperatures above 40°C (104°F) begins to break the polyurethane polymer chains, leading to permanent loss of elasticity and shrinkage. This damage is cumulative and irreversible.

- Chlorine Bleach: This powerful oxidizing agent is catastrophic for elastane, causing rapid yellowing and a breakdown of the fiber’s molecular structure, effectively dissolving its strength and stretch.

- Fabric Softeners and Dryer Sheets: These products deposit a thin, hydrophobic coating on fibers. On elastane blends, this coating can trap odor-causing bacteria, reduce the fabric’s moisture-wicking efficiency, and, over time, contribute to the degradation of the fiber’s elasticity.

Drying and Ironing

- Drying: Air-drying flat in a well-ventilated area, away from direct sunlight or radiators, is the single best practice. The concentrated, high heat of a tumble dryer is one of the fastest ways to destroy an elastane garment. If machine drying is unavoidable, use a no-heat or air-fluff setting only.

- Ironing: Direct application of a hot iron can melt elastane fibers on contact. If pressing is necessary to remove wrinkles from a blend, use the absolute lowest temperature setting (often symbolized by a single dot), employ a pressing cloth as a barrier, and keep the iron in constant motion. Steam is a safer alternative for relaxing wrinkles.

Environmental and Health Impact

Toxicity and Health Risks

The fully polymerized elastane fiber in a finished garment is generally considered inert and safe for skin contact. The significant health considerations lie upstream in the manufacturing process and with residual chemicals.

Production involves chemicals like diphenylmethane diisocyanate (MDI) and solvents such as dimethylacetamide (DMAC), which require stringent occupational safety controls for workers due to their toxicity if inhaled.

For consumers, the risk centers on chemical residues from dyeing and finishing. Substances like formaldehyde (used for wrinkle resistance), certain azo dyes, and heavy metals can remain on the fabric. In the warm, moist, and abrasive microclimate created by tight-fitting elastane apparel, the potential for dermal absorption of these residues increases.

Mitigation is possible. Seeking out garments certified by OEKO-TEX® Standard 100 ensures the finished product has been tested for a broad range of harmful substances. For items with prolonged skin contact, like underwear or activewear base layers, choosing blends with a lower elastane content (e.g., below 10%) can also reduce potential exposure.

Environmental Challenges

As a synthetic petrochemical derivative, elastane carries a substantial environmental burden that is now under intense scrutiny.

- Fossil Fuel Dependency and Carbon Footprint: Its production is energy-intensive and relies on non-renewable petroleum, contributing to greenhouse gas emissions.

- Non-Biodegradability: Discarded elastane garments do not decompose in landfills; they persist for decades or centuries, contributing to the massive global problem of textile waste.

- Microfiber Pollution: Every wash of an elastane-blend fabric releases thousands of microplastic fibers. These tiny pollutants bypass water treatment facilities, entering rivers and oceans, where they are ingested by marine life and enter the food chain.

- The Recycling Conundrum: Elastane is the nemesis of textile recycling. Its elastic properties cause it to tangle and wrap around machinery in mechanical recycling plants. Even a small percentage (as low as 2%) can contaminate and ruin a batch of otherwise recyclable polyester or cotton, making most “stretch” garments effectively unrecyclable through conventional means.

Recycling and Future Innovations

Recycling elastane is one of the textile industry’s most complex challenges due to its blended nature and elastic properties, which disrupt standard mechanical recycling. This has spurred investment in advanced molecular recycling technologies.

These next-generation processes, such as chemical depolymerization and selective dissolution, aim to break down elastane and blended fabrics into their core chemical components for purification and reuse. While promising, these technologies face hurdles in scalability, cost, and energy efficiency.

Concurrently, the industry is developing next-generation alternatives, including elastane made with recycled content, partially bio-based feedstocks, and new polymer designs engineered for better end-of-life recyclability. The path to a circular model for stretch fabrics is underway but requires continued innovation and systemic change.

FAQs About Elastane Fabric

Is elastane plastic?

Yes. Elastane is a synthetic polymer made from polyurethane, which means it is technically a type of plastic. Unlike rigid plastics, its long, flexible molecular chains allow it to stretch and recover, making it ideal for performance and stretch fabrics.

What is elastane made from?

Elastane is made from polyurethane-based polymers derived from petrochemicals. These polymers are processed into fine filaments that can stretch 5–8 times their length and return to shape.

Does elastane shrink?

Pure elastane does not shrink, but fabrics containing elastane can. Shrinkage usually comes from the natural fibers in the blend (like cotton) reacting to high heat in washing or drying. Follow garment care instructions and use cool water + low heat to prevent damage.

Is elastane fabric good or bad?

Elastane has clear benefits but also environmental trade-offs:

- Pros: Exceptional stretch, comfort, mobility, and shape retention; essential for activewear, swimwear, and fitted garments.

- Cons: Petrochemical-based, non-biodegradable, and can contribute to microplastic release.

- Bottom line: Elastane is highly effective when used responsibly, especially in blends, but should be considered within sustainability goals.

Conclusion

Elastane fabric is a paradox of modern material science: a fiber of incredible utility shadowed by significant environmental challenges. The future of stretch is not about abandoning elastane but about evolving it. The path forward is being paved with groundbreaking chemical recycling that can unmake and remake it, with bio-based feedstocks that reduce its petroleum dependence, and with smarter fiber design that considers end-of-life from the very beginning.

As consumers, our power lies in informed choices—opting for quality, caring for garments meticulously, supporting innovative brands, and demanding greater circularity. By understanding the full story of elastane, from its molecular architecture to its global impact, we can all contribute to stretching the boundaries of what’s possible toward a more sustainable and functional future.

Navigating the complex world of performance fibers requires a knowledgeable partner. At Tani Thread, we combine deep material expertise with a commitment to innovation, offering guidance on optimal elastane blends for durability, comfort, and evolving sustainability targets. Contact our technical team to explore how our advanced yarn solutions can elevate your next project.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread