In the vast landscape of synthetic fibers, three titans dominate modern textile manufacturing: Elastane, Nylon and Polyester. While often grouped together as “man-made” materials, their chemical structures, performance characteristics, and optimal applications diverge significantly. Understanding the differences between Elastane vs. Polyester vs. Nylon is not merely academic—it is a critical competency for designers, product developers, and manufacturers aiming to create fabrics that perfectly balance performance, cost, and consumer expectations.

Both Nylon and Polyester are synthetic polymers derived from petrochemicals, manufactured into fibers through processes of polymerization and extrusion. Nylon, chemically a polyamide, is celebrated for its incredible strength and silk-like feel, while Polyester (PET) is ubiquitous for its durability, wrinkle resistance, and hydrophobic nature. Together, they form the foundational backbone of global textile production.

Elastane (also known as Spandex or Lycra), however, occupies a unique niche. Engineered not for strength but for one unparalleled property—exceptional elasticity—it is the quintessential performance enhancer. Rarely used alone, it is strategically blended in small percentages with fibers like polyester or nylon. This synergy creates the stretch fabrics essential for modern comfort and fit, making an understanding of blends like polyamide and elastane fabric or poly elastane fabric crucial.

For anyone in the textile value chain, distinguishing between these materials is paramount. A misinformed choice can lead to product failure, increased costs, or sustainability setbacks. This guide provides a detailed, side-by-side performance comparison of Elastane, Nylon and Polyester, delving into their applications, cost structures, and environmental footprints to empower smarter, more strategic material selection.

Performance Comparison: Elastane vs. Polyester vs. Nylon

To navigate the strengths and weaknesses of each fiber, we begin with a high-level summary before diving into specific attributes.

Summary Comparison Table

| Attribute | Elastane (Spandex/Lycra) | Nylon (Polyamide) | Polyester (PET) |

| Primary Trait | Exceptional Elasticity | High Strength & Abrasion Resistance | Durability & Quick-Drying |

| Durability | Low (Needs Support) | Excellent | Very Good |

| Moisture Behavior | Hydrophilic | Absorbs Moisture (4-4.5%) | Hydrophobic |

| Handfeel | Smooth, Soft | Soft, Silky | Can be Crisp or Brushed |

| Elastic Recovery | 95-99% | Good (Better than Polyester) | Limited |

| Heat Resistance | Poor (Degrades ~180°C) | Moderate (Melts at lower temp) | Good |

| UV Resistance | Poor | Poor (without stabilizers) | Good |

| Typical Apparel Use | Blended for Stretch | Activewear, Hosiery, Swimwear | Sportswear, Outerwear |

Durability and Abrasion Resistance

- Elastane has relatively low tensile strength and poor abrasion resistance on its own. Its durability in a final fabric is entirely dependent on the fibers it is blended with. The protective sheath in a covered yarn or the matrix in a core-spun yarn shields the delicate elastane filaments from direct wear and tear.

- Nylon is the undisputed champion in this category. Renowned for its superior abrasion resistance and high tensile strength, it can withstand significant friction and stress. A critical advantage is its performance when wet; nylon retains about 94% of its strength, making it ideal for applications like climbing ropes, heavy-duty luggage, and performance gear that may be exposed to moisture.

- Polyester is also highly durable and strong, but generally falls slightly short of nylon in terms of long-term abrasion resistance. However, it retains about 90% of its strength when wet and excels in resistance to stretching and shrinking, contributing to the dimensional stability of fabrics. For everyday durable items and apparel that requires shape retention, polyester is a top choice.

Moisture Management and Handfeel

- Elastane fibers themselves are smooth and soft, contributing a comfortable handfeel. However, their primary function is not moisture management but stretching.

- Nylon absorbs a small amount of moisture (4-4.5% moisture regain), which gives it a softer, silkier texture against the skin—a key reason it is favored for items like lingerie, yoga wear, and premium leggings. This absorption, however, means it dries more slowly than polyester, as water is held within the fiber.

- Polyester is inherently hydrophobic. It repels water, forcing moisture (like sweat) to wick along the fiber surface and evaporate quickly. This makes it the fastest-drying of the three, a decisive factor for sportswear, outdoor jackets, and base layers where rapid moisture removal is essential to maintain thermal comfort.

Elasticity and Recovery

- Elastane is in a league of its own. It can typically stretch 500-800% of its original length and recover nearly completely (95-99% recovery). This exceptional elasticity and memory are why even a small percentage blended into a fabric can transform its performance, providing all-day comfort and shape retention.

- Nylon possesses a natural stretchiness and recovery superior to polyester, owing to its molecular chain flexibility. It can elongate significantly and return to shape well, which is why it performs admirably in hosiery and form-fitting activewear even without added elastane.

- Polyester has very limited innate stretch (typically 20-35% elongation at break) and poorer recovery. A 100% polyester fabric will feel more rigid and is prone to permanent deformation if overstretched. This is precisely why poly elastane fabric blends are so popular—polyester provides durability and quick-drying, while elastane supplies the necessary stretch.

Heat Resistance and UV Stability

- Elastane is thermosensitive. The urethane bonds in elastane begin to soften around 180°C and degrade at 220–230°C. This requires careful control during dyeing and finishing, with temperatures ideally kept below 170°C to prevent damage and loss of elasticity.

- Nylon has a lower melting point than polyester and is particularly susceptible to degradation from prolonged UV exposure (sunlight), which can cause it to yellow and lose strength unless treated with UV stabilizers.

- Polyester generally offers better heat resistance than nylon and has inherent UV stability due to its aromatic polymer structure. It resists degradation from sunlight much more effectively, making it the preferred choice for outdoor applications like awnings, flags, and upholstery that face constant sun exposure.

Applications in Production and Consumption

Elastane

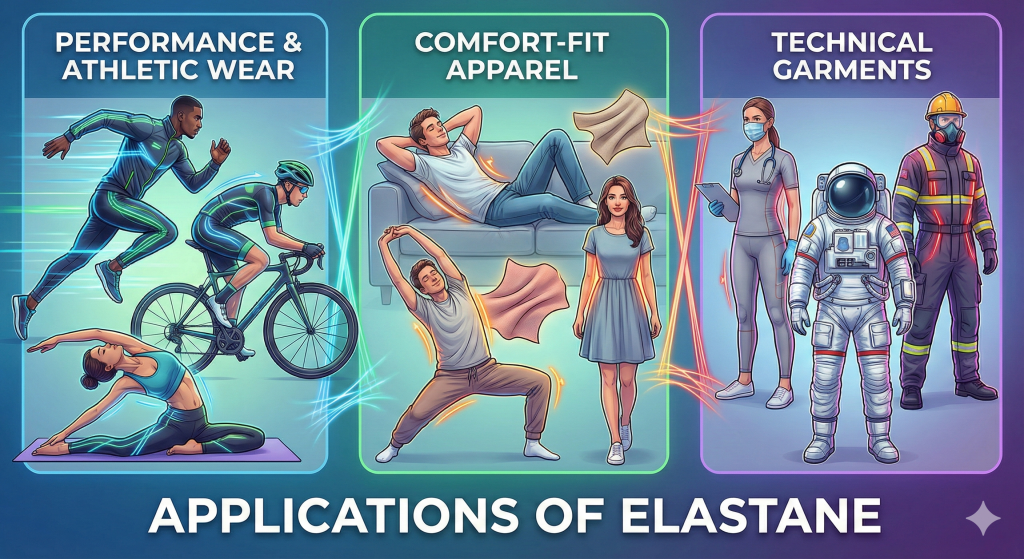

Elastane’s role is specialized and transformative. As a key component in polyamide and elastane fabric or cotton-elastane blends, its primary uses are:

- Performance & Athletic Wear: Swimwear, cycling shorts, and dance costumes rely on its powerful, consistent recovery.

- Comfort-Fit Apparel: It is essential in modern denim, t-shirts, and yoga wear for providing comfortable stretch.

- Technical Garments: It is the core of shapewear, compression socks, and medical braces where controlled elasticity is the primary function.

Nylon

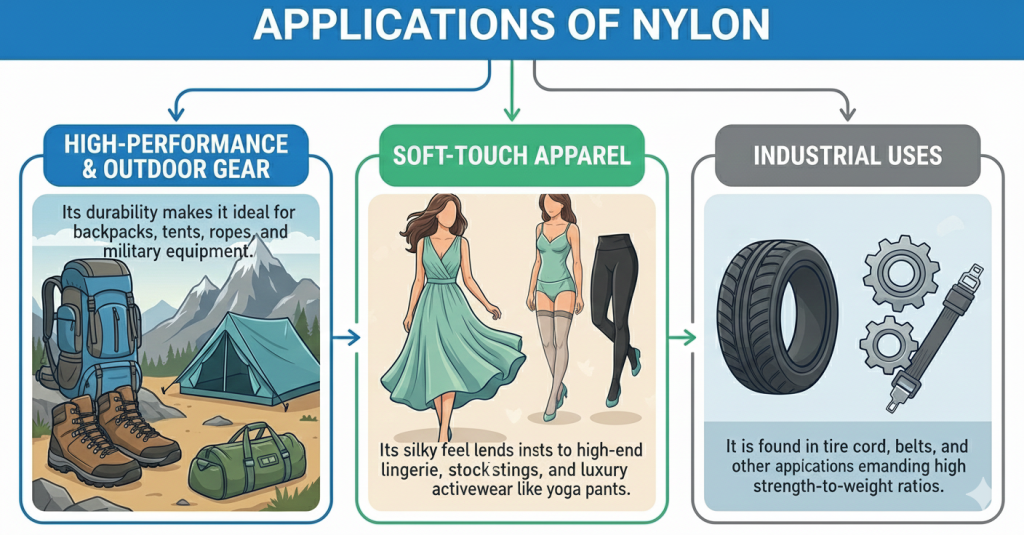

Nylon’s blend of strength, elasticity, and a soft handfeel makes it versatile:

- High-Performance & Outdoor Gear: Its durability makes it ideal for backpacks, tents, ropes, and military equipment.

- Soft-Touch Apparel: Its silky feel lends itself to high-end lingerie, stockings, and luxury activewear like yoga pants.

- Industrial Uses: It is found in tire cords, seat belts, and other applications demanding high strength-to-weight ratios.

Polyester

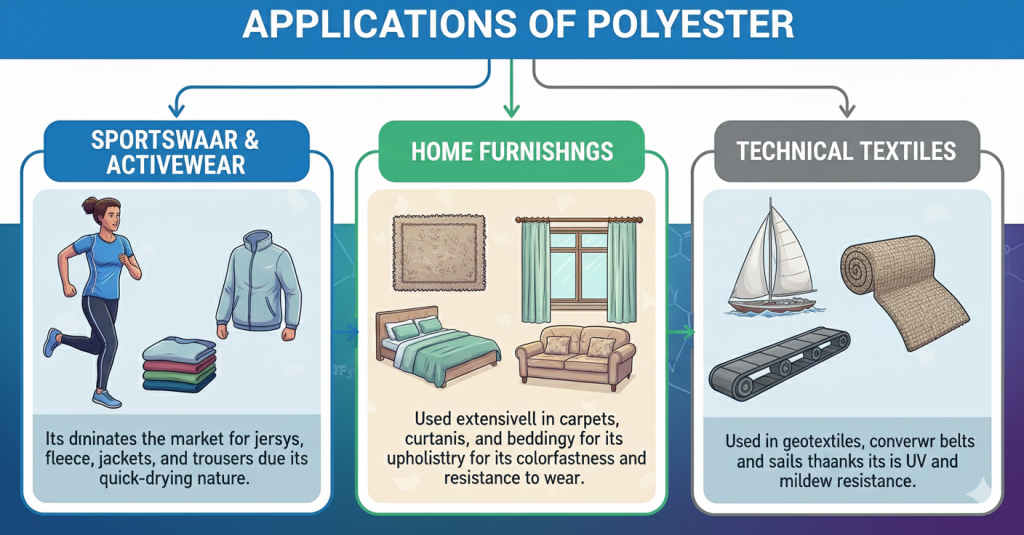

Polyester’s durability, resilience, and moisture-wicking properties grant it the widest range of applications:

- Sportswear & Activewear: Dominates the market for jerseys, fleece, jackets, and trousers due to its quick-drying nature.

- Home Furnishings: Used extensively in carpets, curtains, bedding, and upholstery for its colorfastness and resistance to wear.

- Technical Textiles: Used in geotextiles, conveyor belts, and sails thanks to its UV and mildew resistance.

Cost and Sustainability

Cost Analysis

- Nylon is generally the most expensive of the three for virgin fiber production. The chemical process (polycondensation) is complex, energy-intensive, and requires precise purification.

- Polyester is typically the most cost-effective. Its production process is well-optimized at a massive global scale, and raw materials are less expensive, making poly elastane fabric a very economical route to stretch performance.

- Elastane is a premium specialty fiber. Its complex production and the proprietary nature of many brands (like Lycra®) place its cost above that of standard polyester, though it is used in such small percentages that its impact on final fabric cost is moderate.

Environmental Impact and Recycling

All three fibers face significant sustainability challenges as petrochemical-based, non-biodegradable materials. They contribute to microplastic pollution, especially through laundry shedding.

Carbon Footprint: Virgin Nylon production generates approximately 9.0 kg of CO₂ equivalent per kg, roughly double that of Virgin Polyester (~4.5 kg CO₂e/kg).

Recycling Pathways:

- Polyester (rPET) leads in circularity. A mature infrastructure exists for recycling PET bottles into fiber, reducing emissions to about 2.0 kg CO₂e/kg.

- Nylon (rPA) recycling (e.g., Econyl® from fishing nets) is growing but is less mature and more costly than rPET recycling, with emissions around 4.5 kg CO₂e/kg.

- Elastane recycling presents the greatest challenge. Even small amounts (5%) can contaminate and disrupt mechanical recycling streams for other fibers. Chemical recycling (solvolysis) is a promising but not yet scalable solution, making polyamide and elastane blends particularly difficult to recycle at end-of-life.

FAQs: Elastane, Polyester, and Nylon

Which is more stretchy: nylon or polyester?

Nylon is inherently more stretchy and has better recovery than polyester. However, for significant, garment-defining stretch, both are typically blended with elastane.

Can elastane be recycled?

Mechanical recycling of fabrics containing elastane is extremely difficult and often renders the output unusable. Chemical recycling technologies that can separate elastane from other fibers are under development but are not yet commercially widespread.

Is polyamide the same as nylon?

Yes, “nylon” is the common brand name for a type of synthetic polymer scientifically classified as a polyamide.

What is better for summer: polyester or nylon?

Polyester is often considered better for high-heat, high-sweat summer activities because it is hydrophobic and dries very quickly, wicking moisture away from the body. Nylon’s moisture absorption can feel clingier when wet with sweat.

Why is elastane always blended?

Elastane lacks the durability, strength, and often the desired handfeel for use as a standalone fabric. Blending it with fibers like polyester, nylon, or cotton combines the comfort of stretch with the practical performance characteristics of the other material.

Conclusion

The choice between Elastane, Nylon and Polyester is not about finding the “best” fiber, but about identifying the right tool for the job. Nylon excels where supreme strength, abrasion resistance, and a soft feel are critical. Polyester is the champion of durability, quick-drying performance, and cost-effective versatility. Elastane is the irreplaceable specialist, injecting essential stretch and recovery into fabrics to meet modern demands for comfort and fit.

In practice, their synergy is most powerful. Blends like polyamide and elastane or poly elastane fabric leverage the strengths of each to create superior materials. As the industry advances, the challenge and opportunity lie in innovating not just in performance, but in enhancing the sustainability and circularity of these foundational synthetic fibers.

Ready to specify the perfect material for your next project? Contact our technical team today for a consultation on polyester, nylon, and elastane blends tailored to your specific performance, cost, and sustainability goals.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread