In today’s advanced textile industry, polyamide elastane fabric — often referred to as nylon elastane or nylon Lycra—has become a cornerstone material for high-end fashion, activewear, and performance-driven applications. By combining exceptional mechanical strength with outstanding elasticity, this fabric delivers a rare balance of durability, comfort, and freedom of movement.

This article provides a comprehensive overview of polyamide elastane fabric, including its composition, key performance properties, common blend ratios, real-world applications, and best practices for care and maintenance.

What Is Polyamide Elastane Fabric?

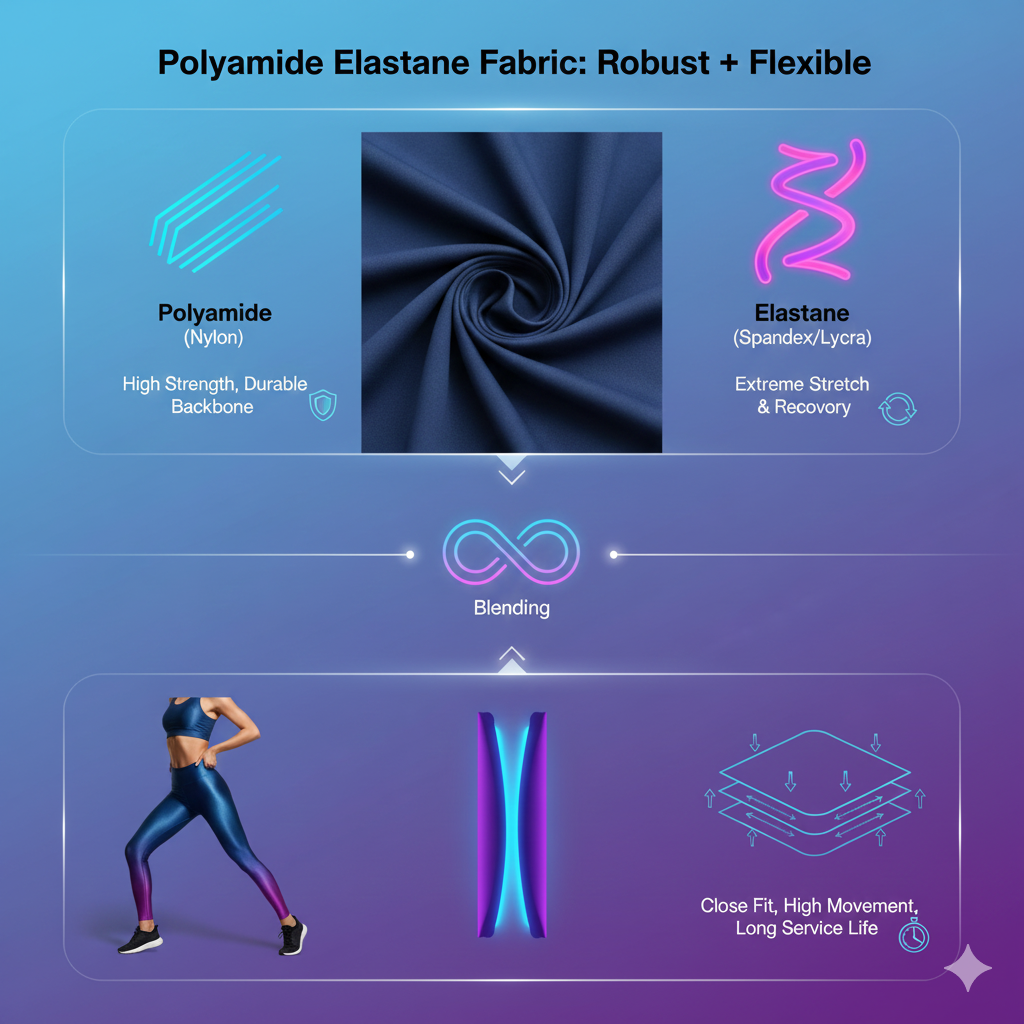

Polyamide elastane fabric is a composite textile created by blending two synthetic fibers: polyamide (nylon) and elastane (spandex/Lycra). Each component plays a distinct functional role within the fabric structure.

Polyamide serves as the structural backbone of the fabric, offering high tensile strength, excellent abrasion resistance, and long-term durability. Elastane, on the other hand, provides exceptional stretch and recovery, allowing the fabric to extend several times its original length and return to its initial shape without permanent deformation.

The result is a fabric that is both robust and highly flexible, making it particularly suitable for garments that demand close fit, repeated movement, and long service life.

While both Polyamide (Nylon) and Polyester blends offer durability, they possess distinct characteristics that suit different applications. Blending synthetic fibers with Elastane (Spandex/Lycra®) is essential for achieving the stretch and recovery required for modern apparel. For Polyamide Elastane Fabric vs Polyester Elastane Fabric, the quality of the stretch is determined at the yarn level.

Key Performance Properties of Polyamide Elastane Fabric

The widespread adoption of polyamide elastane fabric across premium apparel segments is driven by a combination of advanced technical characteristics.

- Four-Way Stretch and Recovery: Polyamide elastane fabrics typically offer true four-way stretch, enabling unrestricted movement in all directions. This property is critical for high-intensity sports, swimwear, yoga apparel, and compression garments, where mobility and shape retention directly affect performance.

- Durability and Shape Stability: Thanks to the inherent strength of polyamide, these fabrics demonstrate excellent resistance to abrasion, pilling, and tearing. Garments retain their original fit and appearance even after repeated wear and laundering. However, while polyamide elastane is highly abrasion-resistant, it is more sensitive to prolonged UV exposure and requires appropriate care to maintain long-term performance.

- Soft, Premium Hand Feel: Compared to many other synthetic fabrics, polyamide elastane offers a notably smooth and silky surface, often described as a “second-skin” sensation. This tactile quality makes it especially attractive for premium fashion, intimates, and body-hugging athletic designs.

- Moisture Management: Polyamide fibers are moderately hydrophilic, allowing them to absorb and disperse moisture more effectively than polyester-based fabrics. This contributes to improved wearer comfort during physical activity by reducing clamminess and supporting thermal regulation.

- Chemical Resistance: Polyamide elastane fabrics exhibit good resistance to body oils, sunscreens, and cosmetic products, which helps preserve fiber integrity over time. However, due to their moisture-absorbing nature, these fabrics do not possess inherent mold resistance and should be properly dried and stored in humid environments.

Common Blend Ratios and Practical Applications

The performance of polyamide elastane fabric can be fine-tuned by adjusting the fiber ratio to suit specific end uses.

- 92% Polyamide / 8% Elastane: This blend provides moderate stretch with reliable shape support. It is commonly used for swimwear, bras, and light compression garments where controlled elasticity is essential.

- 80% Polyamide / 20% Elastane: One of the most popular ratios, this composition balances flexibility and durability. It is widely applied in leggings, yoga wear, and gym apparel.

- 70% Polyamide / 30% Elastane: Designed for maximum stretch and body conformity, this blend is typically reserved for professional sportswear, technical performance garments, and shapewear.

Key Application Areas

Polyamide elastane fabric is used across multiple industries, including:

- Sportswear and swimwear: where stretch, durability, and quick-drying performance are critical

- Premium fashion: valued for its drape, sheen, and smooth hand feel

- Medical textiles: such as compression stockings and support bandages

- Workwear and protective clothing: where flexibility enhances comfort and productivity

Care and Maintenance Guidelines

Proper care is essential to preserve the elasticity and lifespan of polyamide elastane garments. Recommended practices include washing in cold water on gentle cycles, avoiding fabric softeners and bleaching agents, and drying flat or at very low temperatures. Folding garments instead of hanging them also helps maintain elastic recovery over time.

Conclusion

Polyamide elastane fabric is more than just a textile choice—it is a strategic investment in performance, comfort, and product quality. Its unique combination of strength, stretch, softness, and moisture management makes it an indispensable material for premium apparel and high-performance applications. For manufacturers, designers, and sourcing professionals, understanding the technical advantages and limitations of this fabric enables more informed decisions and better end-product outcomes. As demand for functional yet comfortable garments continues to grow, polyamide elastane fabric remains a key material shaping the future of advanced apparel.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread