This article provides a technical, side-by-side comparison of Polyamide elastane and Polyester elastane, analyzing their chemical composition, elasticity, moisture management, durability, and commercial suitability. The goal is to help brands, designers, and manufacturers select the optimal fabric solution based on specific end-use requirements while balancing performance, comfort, and sustainability.

Understanding Polyamide Elastane Fabric and Polyester Elastane Fabric

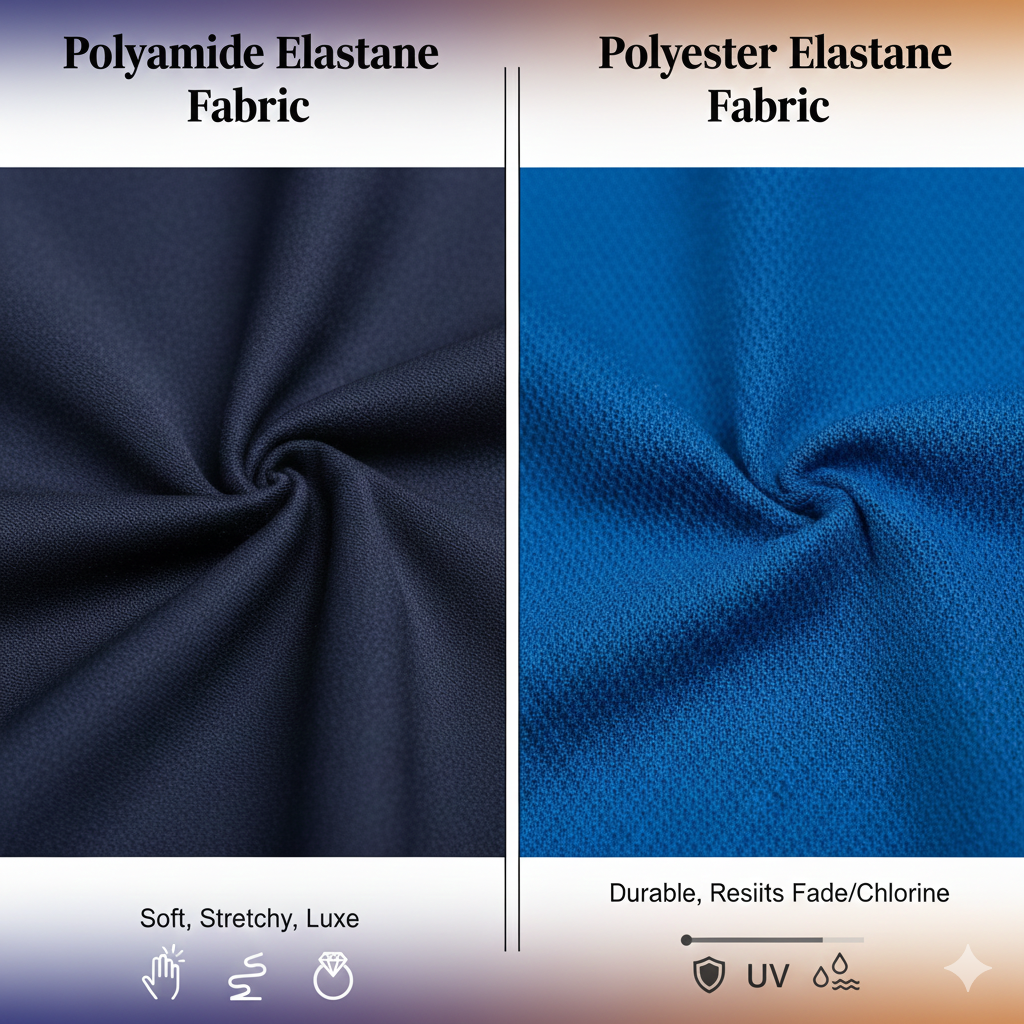

Polyamide elastane and polyester elastane are the two most widely used fabric constructions in modern activewear and swimwear manufacturing. While both rely on elastane to deliver stretch and flexibility, the choice of the base fiber—nylon or polyester—fundamentally determines performance, comfort, durability, cost efficiency, and long-term product value.

Polyamide Elastane Fabric

Polyamide elastane—also known as polyamide spandex—is produced by blending nylon fibers with elastane (spandex/Lycra). Nylon’s linear molecular structure gives the fiber excellent mechanical strength, flexibility, and resilience, resulting in fabrics with superior stretch, smoothness, and a premium hand feel.

This fabric construction is widely recognized for its high elasticity, fast recovery, and luxurious surface, making it a preferred choice for high-performance and high-end apparel.

Polyester Elastane Fabric

Polyester elastane combines polyester (polyethylene terephthalate – PET) with elastane. Polyester is known for its dimensional stability, wrinkle resistance, colorfastness, and chemical resistance. Compared to nylon, polyester offers a more rigid molecular structure, translating into enhanced durability and production consistency.

As a result, Polyester elastane is widely used in cost-sensitive, large-scale production, particularly where color retention and long-term durability are critical.

Key Differences Between Polyamide Elastane Fabric and Polyester Elastane Fabric

For both fabric types, the quality of the stretch is determined at the yarn level. Polyamide elastane offers superior comfort and stretch, making it ideal for premium activewear and intimate apparel. Polyester elastane provides excellent durability and value, perfect for everyday athletic wear and performance clothing where cost-effectiveness matters.

Comparative Overview

| Criteria | Polyamide Elastane | Polyester Elastane |

| Stretch & Recovery | Excellent 4-way stretch, fast recovery | Good stretch, slower recovery |

| Surface Hand Feel | Soft, smooth, premium | Drier, firmer, slightly textured |

| Luster | Light natural sheen | Typically matte |

| Moisture Management | Hydrophilic, absorbs moisture | Hydrophobic, quick-drying |

| Color Retention | Moderate, may fade under UV | Excellent colorfastness |

| Mold & Chemical Resistance | No natural resistance | Strong resistance to mold & chemicals |

| Cost | Higher, premium positioning | Cost-effective, mass production |

Detailed Performance Analysis

- Elasticity and Shape Recovery: Polyamide elastane delivers superior multi-directional stretch, particularly 4-way elasticity, allowing garments to move seamlessly with the body. Its fast recovery prevents sagging and deformation, maintaining garment shape even after extended wear. Polyester elastane offers reliable elasticity but generally exhibits lower rebound performance compared to nylon-based constructions.

- Comfort and Hand Feel: Polyamide elastane is widely regarded for its silky smooth texture and skin-friendly comfort, making it ideal for tight-fitting and next-to-skin garments. The fabric feels lighter, softer, and more breathable. Polyester elastane, while durable, tends to feel firmer and drier, offering structure rather than luxury comfort.

- Moisture Management: Nylon fibers are hydrophilic, with a moisture regain of approximately 4%, allowing them to absorb sweat and enhance thermal comfort during moderate activity. Polyester fibers are hydrophobic, meaning moisture remains on the fabric surface and evaporates quickly. While polyester dries faster, nylon generally provides better comfort during prolonged wear.

- Durability and Care: Polyester elastane outperforms nylon in terms of resistance to UV exposure, chlorine, chemicals, and repeated washing. It retains color vibrancy and structural integrity even under harsh conditions. Polyamide elastane is highly abrasion-resistant but more sensitive to sunlight and requires gentler care to preserve performance.

- Mold and Chemical Resistance: Thanks to its hydrophobic nature, Polyester elastane resists mold, mildew, and chemical degradation more effectively. Polyamide elastane, being moisture-absorbent, does not possess natural anti-mold properties and requires careful storage and maintenance in humid environments.

- Cost and Commercial Viability: Polyester elastane offers a significant cost advantage, making it suitable for large-volume, price-sensitive markets. Polyamide elastane commands a higher price due to its premium characteristics and is typically reserved for technical, performance-driven, or luxury segments.

Practical Guidelines for Fabric Selection

- For applications such as yoga wear, professional intimates, compression garments, and high-performance swimwear, Polyamide elastane remains the preferred choice. Its superior stretch, smooth hand feel, and “second-skin” comfort support intensive movement and premium consumer experiences.

- For athleisure, everyday sportswear, and commercial swimwear, Polyester elastane provides an optimal balance between durability, cost efficiency, and color performance. It is particularly suitable for garments requiring vibrant prints, frequent washing, and long service life.

Choosing the Right Material Strategy

The choice between Polyamide elastane and Polyester elastane is not about superiority, but strategic alignment with product intent. Nylon excels in comfort, elasticity, and premium aesthetics, while polyester dominates in durability, color retention, and economic scalability.

A well-informed material selection allows brands to optimize performance, user experience, production efficiency, and market positioning—key success factors in today’s competitive activewear and swimwear industry.

Frequently Asked Questions (FAQs)

Is 95 polyester 5 elastane fabric stretchy enough for activewear?

Yes, 95% polyester with 5% elastane (spandex) is an excellent blend for activewear, offering great stretch, shape retention, durability, and comfort for activities like yoga, running, and general fitness, thanks to the elastane providing flexibility while polyester ensures moisture-wicking and structure.

What is the difference between polyamide elastane fabric and polyester elastane fabric?

Polyamide elastane offers superior softness, stretch recovery, and durability (better abrasion resistance) for high-performance wear, absorbing more moisture but feeling silkier; while polyester elastane is more affordable, dries faster due to being hydrophobic, resists wrinkles and chemicals (like chlorine), and is great for everyday activewear but generally less durable and soft.

What is 90 polyamide 10 elastane commonly used for?

A 90% polyamide (nylon) and 10% elastane (spandex) blend is popular for high-performance activewear, swimwear, yoga apparel, and shapewear due to its excellent stretch, shape retention, durability, smooth feel, and moisture-wicking properties, making it ideal for body-hugging garments that require freedom of movement. It’s also used for everyday wear like soft leggings, comfortable dresses, and durable workwear, offering both comfort and resilience.

From Fiber to Fabric Performance: The Role of Covered Yarn

At the core of both Polyamide elastane and Polyester elastane fabrics lies a critical component: covered yarn.

At Tani Thread, we specialize in the production and export of high-quality covered yarns, combining spandex cores with nylon or polyester sheaths to achieve precise elasticity, recovery, surface performance, and durability. With deep expertise in serving the U.S. apparel market, we understand the stringent technical, consistency, and compliance requirements demanded by global brands.

Whether your application prioritizes premium comfort or long-term durability, our covered yarn solutions are engineered to support stable fabric performance, efficient production, and consistent quality at scale.

Looking to optimize your fabric performance from the yarn level?

Contact Tani Thread today to discuss your covered yarn specifications and sourcing needs.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread