In the ever-evolving world of design and technology, a groundbreaking innovation has emerged from the halls of Carnegie Mellon University. Researchers have developed a revolutionary ‘robotic’ machine that employs a technique called Solid Knitting to create three-dimensional furniture and accessories using only elastic cord or yarn. This remarkable advancement in fabrication technology promises to transform the way we think about furniture design and production, offering a sustainable and customizable alternative to traditional manufacturing methods.

The Birth of Solid Knitting: A New Frontier in Fabrication

From Concept to Reality: The Journey of Solid Knitting

The concept of Solid Knitting was born from the visionary mind of Yuichi Hirose, a robotics Ph.D. student at Carnegie Mellon University’s School of Computer Science. Hirose’s dream of a machine capable of knitting not just fabric, but entire pieces of furniture, began to take shape in 2018. This ambitious project aimed to create a system that could fashion 3D chairs, tables, and other objects using nothing more than yarn or elastic cord.

As Hirose worked on developing his Solid Knitting machine, he discovered the software project of James McCann, an associate professor in Carnegie Mellon’s Robotics Institute. Recognizing the potential synergy between their work, Hirose reached out to McCann, leading to a collaboration that would push the boundaries of what was possible in the realm of fabrication technology.

In 2021, Hirose joined McCann’s Textiles Lab as a research assistant, later transitioning into the Ph.D. program in robotics. This partnership, along with the contributions of other team members like Angelica Bonilla Fominaya and Mark Gillespie, has been instrumental in bringing the Solid Knitting machine from concept to reality.

Understanding Solid Knitting: A New Approach to 3D Object Creation

Solid Knitting represents a paradigm shift in how we create three-dimensional objects. Unlike 3D printing, which builds objects by depositing layers of material, Solid Knitting weaves shapes and objects using knitted layers. This technique relies on the intricate interplay of elastic cord or yarn, stitched together to form solid structures without the need for glue or supporting plastics.

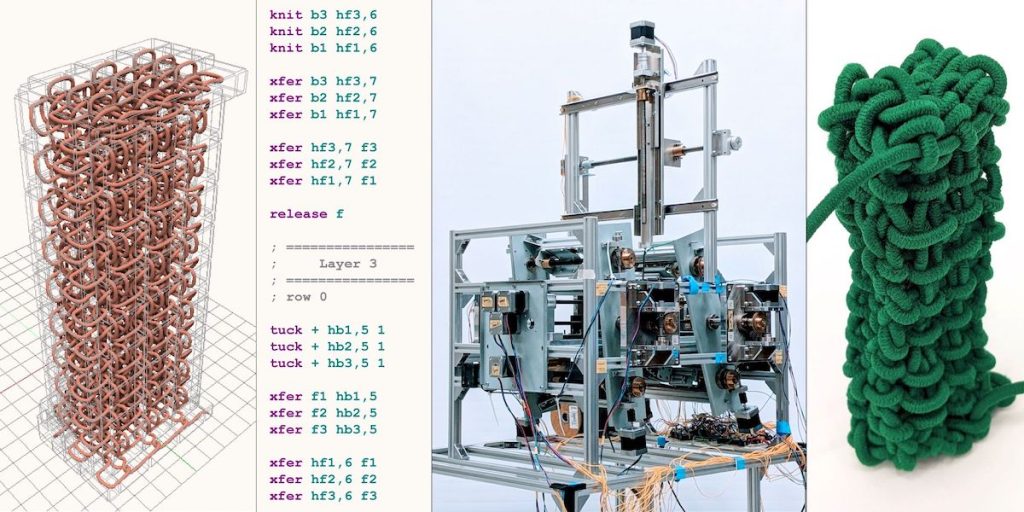

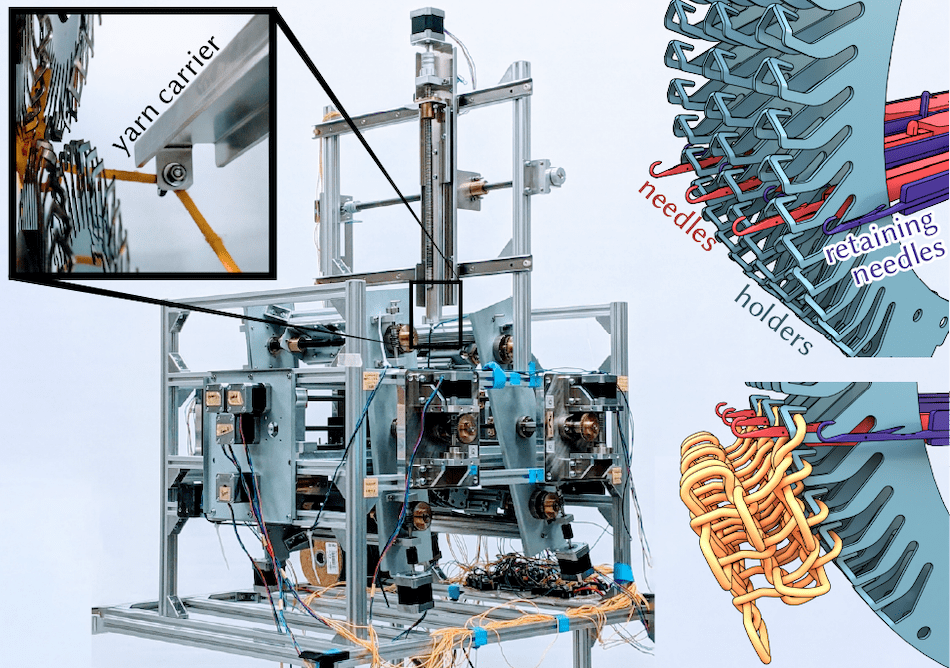

The current prototype machine, about the size of a clothes dryer, features rows of latch needles – hooked needles with latches that can be opened and closed. These needles work in concert with sophisticated software to produce customized 3D knitted pieces. The user inputs a design, and the machine meticulously loops and ties the yarn or elastic cord, building the object layer by layer until the desired furniture, accessory, or object is complete.

While the current prototype is limited to producing triangular or rectangular prisms, the potential for expansion and refinement is immense. The researchers are actively working on improving the machine’s capabilities, with plans to create both larger machines for furniture production and smaller, more precise machines for intricate objects.

The Power of Covered Elastic Yarn in Solid Knitting

At the heart of the Solid Knitting process lies the choice of material: covered elastic yarn. This innovative material plays a crucial role in the success of the technique, offering a unique combination of flexibility and strength that traditional yarns cannot match.

Covered elastic yarn consists of an elastic core wrapped with a non-elastic fiber, typically cotton or polyester. This construction allows the yarn to stretch and recover its shape, making it ideal for creating solid, three-dimensional objects that maintain their form over time.

The researchers found that using covered elastic yarn was essential for achieving the desired results in Solid Knitting. The elasticity of the material allows for the stretching and manipulation necessary to create complex shapes, while its recovery properties ensure that the finished objects retain their structure and stability.

Moreover, the use of covered elastic yarn contributes to the sustainability aspect of Solid Knitting. Unlike traditional furniture manufacturing, which often involves non-recyclable materials and complex assembly processes, objects created through Solid Knitting can be easily unraveled and the yarn reused to create new pieces. This aligns perfectly with the growing demand for sustainable and adaptable design solutions in our rapidly changing world.

The Technology Behind Solid Knitting: Merging Robotics and Textiles

The Anatomy of the Solid Knitting Machine

The Solid Knitting machine represents a fascinating convergence of robotics and textile engineering. At its core, the machine is built around a system of latch needles, which are the workhorses of the knitting process. These specialized needles feature hooks with latches that can be opened and closed, allowing them to manipulate the yarn with precision and create complex stitching patterns.

The machine’s framework is designed to hold these needles in rows, creating a knitting bed that can accommodate various sizes and shapes of objects. The current prototype, while limited in size, demonstrates the potential for scaling up to larger furniture pieces or down to more intricate, smaller objects.

One of the key innovations in the Solid Knitting machine is its ability to create three-dimensional structures directly, without the need for additional supporting materials or post-processing. This is achieved through a combination of specialized knitting techniques and the unique properties of the covered elastic yarn used in the process.

The machine’s operation is controlled by sophisticated software that translates digital designs into knitting instructions. This software is the brain of the operation, coordinating the movement of needles, the feeding of yarn, and the creation of complex stitch patterns to build up the desired object layer by layer.

Software Innovation: Translating Designs into Knitted Reality

The software driving the Solid Knitting machine is a critical component of the system’s success. Developed by James McCann and his team, this software represents a significant advancement in the field of computational textiles.

At its most basic level, the software takes a 3D model of the desired object and breaks it down into a series of knittable layers. But the complexity goes far beyond simple slicing. The software must account for the unique properties of knitted structures, including the way different stitch patterns affect the strength, flexibility, and appearance of the final object.

One of the key challenges addressed by the software is the translation of smooth, curved surfaces into knittable structures. This involves complex algorithms that determine how to best approximate curves using the discrete nature of knitted stitches. The software also optimizes the knitting process to ensure structural integrity, managing factors such as yarn tension and stitch density to create solid, stable objects.

Another innovative aspect of the software is its ability to incorporate different stitch patterns and structures within a single object. This allows for the creation of furniture and accessories with varying properties in different areas – for example, a chair seat might be knitted with a denser, more supportive structure, while the backrest could incorporate a more open, breathable pattern.

Pushing the Boundaries: Current Limitations and Future Developments

While the current Solid Knitting prototype represents a significant breakthrough, it’s important to acknowledge its limitations and the challenges that lie ahead. The researchers are actively working to overcome these hurdles and expand the capabilities of the technology.

One of the primary limitations of the current system is the size of objects it can produce. The prototype machine is constrained to creating relatively small pieces, limiting its immediate applications in furniture design. However, the team is already planning to build larger machines capable of knitting full-sized furniture pieces, opening up exciting possibilities for customized, on-demand furniture production.

Another area of focus is expanding the range of shapes and structures that can be created. While the current system excels at producing triangular and rectangular prisms, the goal is to develop techniques for creating more complex geometries, including curved and organic forms. This will require advancements in both the mechanical systems of the machine and the software algorithms that guide the knitting process.

The researchers are also exploring the use of different materials beyond covered elastic yarn. While this material has proven highly effective for creating solid, stable structures, there’s potential to incorporate other types of yarn or even non-textile materials to create hybrid objects with unique properties.

Looking to the future, the team envisions a world where Solid Knitting machines could become commonplace in homes and design studios, allowing individuals to create custom furniture and accessories on demand. This could revolutionize not only the furniture industry but also fields such as product design, fashion, and even architecture.

Applications and Implications of Solid Knitting Technology

Reimagining Furniture Design and Production

The advent of Solid Knitting technology opens up a world of possibilities in furniture design and production. This innovative approach challenges traditional manufacturing methods and offers a new paradigm for creating functional, customizable, and sustainable furniture.

One of the most exciting aspects of Solid Knitting is its potential for mass customization. Unlike traditional furniture manufacturing, which often relies on standardized designs and large production runs, Solid Knitting allows for easy customization of each piece. Designers and consumers alike could potentially tweak designs to suit individual preferences, adjusting factors such as size, shape, pattern, and even structural properties.

This level of customization extends beyond aesthetics. The ability to vary stitch patterns and densities within a single piece of furniture opens up new avenues for ergonomic design. For example, a chair could be knitted with different levels of support in various areas, optimizing comfort and posture support for the user.

From a production standpoint, Solid Knitting offers several advantages. The process is additive, meaning there’s minimal waste compared to traditional subtractive manufacturing methods. Additionally, the ability to create complex shapes and structures in a single process eliminates the need for assembly of multiple parts, potentially streamlining production and reducing costs.

Sustainability and the Circular Economy

In an era where sustainability is increasingly at the forefront of design considerations, Solid Knitting presents an intriguing solution. The use of covered elastic yarn as the primary material offers several environmental benefits.

Firstly, the process is inherently low-waste. Unlike traditional furniture manufacturing, which often involves cutting away excess material, Solid Knitting uses only the amount of yarn needed to create the object. This efficiency in material use can significantly reduce waste in the production process.

Moreover, the potential for easy disassembly and material reuse is a game-changer in terms of sustainability. Imagine a world where, instead of discarding old furniture, consumers could simply unravel their old sofa and use the yarn to knit a new chair or ottoman. This aligns perfectly with the principles of the circular economy, where materials are kept in use for as long as possible.

The use of a single material – covered elastic yarn – also simplifies the recycling process. Traditional furniture often combines multiple materials (wood, metal, foam, fabric) which can be difficult to separate for recycling. In contrast, a Solid Knitted piece could potentially be recycled as a single material stream.

Beyond Furniture: Exploring New Frontiers

While the initial focus of Solid Knitting has been on furniture and accessories, the potential applications of this technology extend far beyond these domains. The ability to create solid, three-dimensional objects from yarn opens up exciting possibilities in various fields.

In the realm of fashion and wearable technology, Solid Knitting could revolutionize the creation of shoes, bags, and other accessories. The technique’s ability to create complex, three-dimensional shapes could lead to innovative designs that are both functional and aesthetically pleasing.

Architectural applications are another area ripe for exploration. While full-scale buildings made entirely from knitted structures may be a distant prospect, there’s potential for creating architectural elements, partitions, or even temporary structures using Solid Knitting techniques.

The medical field could also benefit from this technology. Custom-knitted orthotics, prosthetics, or supportive devices could be tailored to individual patients’ needs, offering improved comfort and functionality.

In the world of product design, Solid Knitting could lead to the creation of unique, textile-based objects that challenge our perceptions of what’s possible with knitted structures. From lampshades to phone cases, the only limit is the designer’s imagination.

Conclusion: Weaving the Future of Design and Manufacturing

The development of Solid Knitting technology at Carnegie Mellon University represents a significant leap forward in the fields of design, manufacturing, and materials science. By harnessing the power of covered elastic yarn and innovative knitting techniques, researchers have opened up new possibilities for creating solid, three-dimensional objects that challenge our traditional notions of furniture and product design.

As this technology continues to evolve and mature, we can anticipate a future where customized, sustainable, and easily recyclable furniture becomes the norm rather than the exception. The potential applications extend far beyond furniture, promising to impact fields as diverse as fashion, architecture, and medical device design.

While challenges remain in scaling up the technology and expanding its capabilities, the foundational work done by the team at Carnegie Mellon University has laid the groundwork for a revolution in how we think about and create the objects that surround us in our daily lives. As we look to the future, it’s clear that Solid Knitting and the use of covered elastic yarn will play a significant role in shaping the next generation of design and manufacturing processes, weaving together innovation, sustainability, and functionality in exciting new ways.