In the world of performance textiles, Spandex and Polyester are two heavyweight contenders, each with distinct properties that make them suitable for different applications. While both are synthetic polymers, their chemical structures and performance characteristics couldn’t be more different.

Understanding the fundamental differences between Spandex vs Polyester is crucial for manufacturers, designers, and brands looking to optimize their product performance, comfort, and durability. This comprehensive guide breaks down their key characteristics, applications, and why their combination often creates the ultimate performance fabric.

Introduction to Spandex and Polyester

- Spandex (also known as elastane or Lycra®) is a synthetic fiber celebrated for its exceptional elasticity. Composed of at least 85% polyurethane, this remarkable fiber can stretch up to 500-600% of its original length and recover completely. Spandex is rarely used alone (typically comprising 2-20% of a blend) but serves as the essential stretch component in fabrics, providing flexibility, shape retention, and form-fitting comfort.

- Polyester is a synthetic fiber derived from petroleum-based polymers, specifically polyethylene terephthalate (PET). Known for its high strength, durability, and resistance to wrinkles and shrinkage, polyester excels in moisture-wicking and quick-drying capabilities. It maintains its shape well under stress and environmental exposure, making it a workhorse fiber for everything from everyday apparel to technical textiles.

Why the Spandex vs Polyester Comparison Matters

The choice between these fibers directly impacts product performance, user experience, and manufacturing outcomes. For sportswear manufacturers, the decision affects compression, moisture management, and garment longevity. For fashion designers, it influences drape, comfort, and aesthetic appeal. Understanding their differences enables better material selection, cost optimization, and targeted product development for specific market needs.

Detailed Comparison: Spandex vs Polyester

Choosing between these synthetic fibers requires understanding their complementary yet distinct characteristics. While both offer durability, their performance profiles serve different purposes in textile applications.

Summary Comparison Table

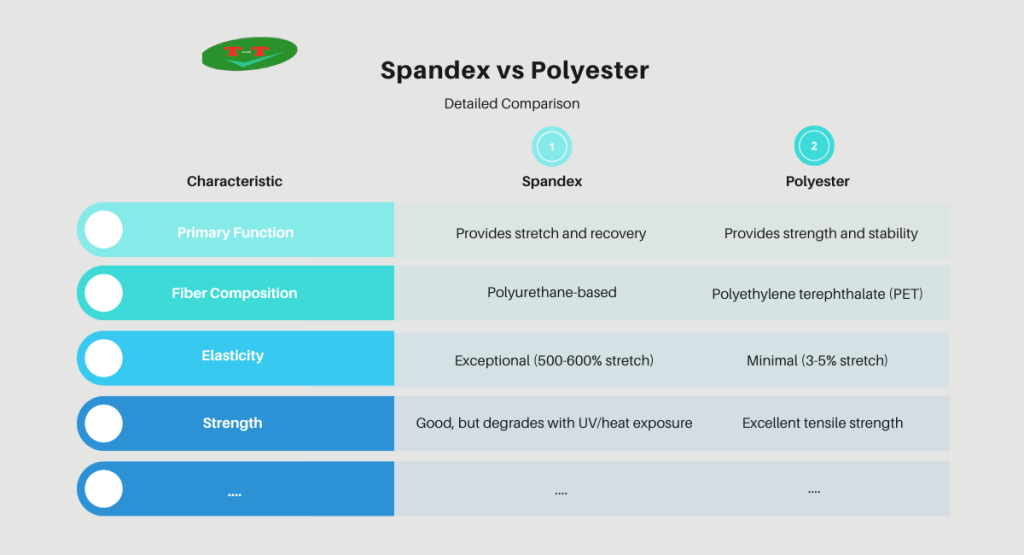

| Characteristic | Spandex | Polyester |

| Primary Function | Provides stretch and recovery | Provides strength and stability |

| Fiber Composition | Polyurethane-based | Polyethylene terephthalate (PET) |

| Elasticity | Exceptional (500-600% stretch) | Minimal (3-5% stretch) |

| Strength | Good, but degrades with UV/heat exposure | Excellent tensile strength |

| Moisture Management | Hydrophobic, minimal wicking | Excellent wicking, quick-drying |

| Breathability | Poor | Moderate to good |

| Heat Sensitivity | High (melts at 250-300°F/121-149°C) | High (melts at 480-550°F/249-288°C) |

| Durability | Good, but affected by chlorine/heat | Excellent long-term durability |

| Environmental Impact | Difficult to recycle, non-biodegradable | Recyclable (rPET), but non-biodegradable |

| Typical Applications | Athletic wear, swimwear, intimate apparel | Sportswear, outdoor gear, everyday fashion |

| Cost Factor | Higher cost per kilogram | Cost-effective, economical |

Detailed Breakdown Comparison

Technical Performance & User Experience

The fundamental difference lies in their core functions: Spandex delivers unparalleled elasticity while Polyester provides structural integrity. Spandex’s incredible stretch capability (500-600%) enables form-fitting garments that move with the body, making it indispensable for compression wear, swimwear, and athletic apparel where freedom of movement is crucial. However, this comes with limitations – Spandex has poor breathability and can feel clammy against the skin during intense activity.

Polyester excels in moisture management, actively wicking sweat away from the body to the fabric surface where it evaporates quickly. This makes it ideal for performance apparel where keeping the wearer dry is paramount. Its superior UV resistance and colorfastness ensure garments maintain their appearance through repeated washing and sun exposure, unlike Spandex which can yellow and degrade under similar conditions.

Long-term Environmental Considerations

Both fibers face environmental challenges as petroleum-based synthetics. Polyester has a more established recycling pathway through rPET (recycled polyester), often made from post-consumer plastic bottles. However, both fibers contribute to microplastic pollution when washed, though polyester’s prevalence makes it a larger contributor. Spandex presents greater recycling challenges due to its elastic properties and is typically downcycled or landfilled. From a longevity perspective, polyester garments generally outlast spandex-heavy items, potentially offsetting some environmental impact through extended use.

Should You Choose Spandex or Polyester?

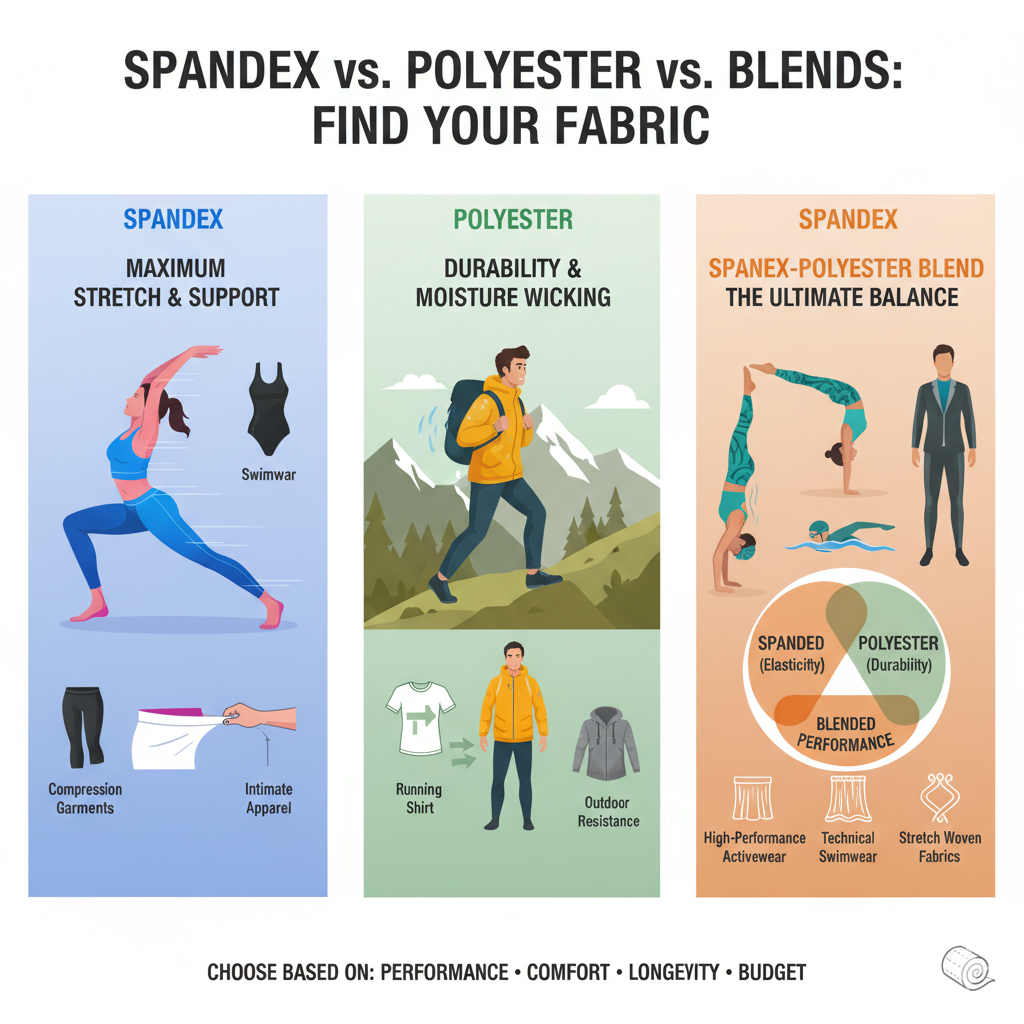

Before choosing between spandex, polyester, or a blended fabric, it is essential to understand your product’s performance requirements, end-use application, and budget expectations. Each fiber offers distinct advantages: spandex excels in stretch and body-contouring support, polyester delivers durability and moisture management, while blends often provide the ideal balance of comfort, stability, and performance.

The right choice depends on whether your priority is elasticity, long-term wear, cost efficiency, or fabric longevity under frequent use. The sections below break down the best use cases for each option to help you make an informed decision.

Best Use Cases for Spandex

Choose Spandex when your primary requirement is significant stretch and recovery. This makes it the unequivocal choice for applications where freedom of movement, a contoured fit, and the ability to maintain shape are non-negotiable. Its unique property of stretching repeatedly and snapping back to its original form is crucial for garments that are meant to move dynamically with the body.

- Compression Garments: Athletic wear, shapewear, medical compression stockings

- Form-Fitting Apparel: Swimwear, dancewear, leggings, skinny jeans

- Comfort-Enhanced Clothing: Waistbands, cuffs, intimate apparel

- Performance Applications: Where freedom of movement is non-negotiable

To inquire about pricing, request samples, or discuss customized spandex yarn solutions, please contact Tani Thread through their official website or customer support channels. Their team is ready to provide professional assistance to support your sourcing needs.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

Best Use Cases for Polyester

Choose Polyester when you prioritize durability and moisture management. This robust synthetic fiber excels in scenarios demanding long-lasting wear, resistance to the elements, and efficient sweat-wicking to keep the wearer dry and comfortable. Its inherent strength and resilience make it ideal for high-use items and outdoor conditions.

- Performance Sportswear: Jerseys, running shirts, athletic uniforms

- Outdoor & Technical Gear: Jackets, raincoats, hiking apparel, backpacks

- Everyday Fashion: Dresses, shirts, pants requiring wrinkle resistance

- Home Textiles: Curtains, upholstery, bedding requiring shape retention

When a Spandex-Polyester Blend Is the Best Option

The combination of Polyester and Spandex (typically 85-95% polyester with 5-15% spandex) creates the ultimate performance fabric for many applications. This blend leverages Polyester’s durability, quick-drying properties, and strength while incorporating Spandex’s flexibility and shape retention. Ideal applications include:

- High-Performance Activewear: Yoga pants, athletic tops, compression wear

- Technical Swimwear: Combining chlorine resistance with perfect fit

- Modern Fashion: Stretch woven fabrics that maintain structure

- Outdoor Apparel: Where both weather resistance and mobility are essential

Conclusion

The Spandex vs Polyester debate isn’t about which fiber is superior, but rather which is better suited for specific applications. Spandex reigns supreme in elasticity and form-fitting comfort, while Polyester dominates in durability, moisture management, and color retention. For most performance applications, the synergistic blend of both fibers creates fabrics that outperform either fiber alone, offering the perfect balance of stretch, recovery, and long-lasting performance. Understanding these differences enables smarter material selection, better product development, and more informed purchasing decisions.

Ready to optimize your fabric selection? Contact our textile experts today for personalized guidance on choosing between Spandex, Polyester, or their ideal blend for your next project. Let us help you create products that perfectly balance performance, comfort, and durability.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread