Driven by the global surge in demand for high-performance activewear, seamless constructions, and sustainable stretch blends, spandex yarn has become a cornerstone of modern textile innovation.

Technically a synthetic, polyurethane-based elastomeric fiber (also known as Lycra or elastane), it is engineered for unparalleled stretch and recovery. It’s typically integrated as a bare filament (common in denims within the 100–140D range) or, more critically, as a covered or core-spun yarn, where it’s wrapped in fibers like cotton or nylon to combine elasticity with a natural feel.

This article provides a comprehensive analysis of the key spandex yarn properties, linking their technical specs directly to the fabric benefits and applications that are shaping today’s apparel industry.

Properties of Spandex Yarn

The unparalleled utility of spandex yarn stems from a unique combination of properties, which can be categorized into mechanical, chemical, and other functional characteristics.

Mechanical and Physical Properties

These are the core properties that define how spandex yarn behaves under stress and strain, directly impacting garment performance.

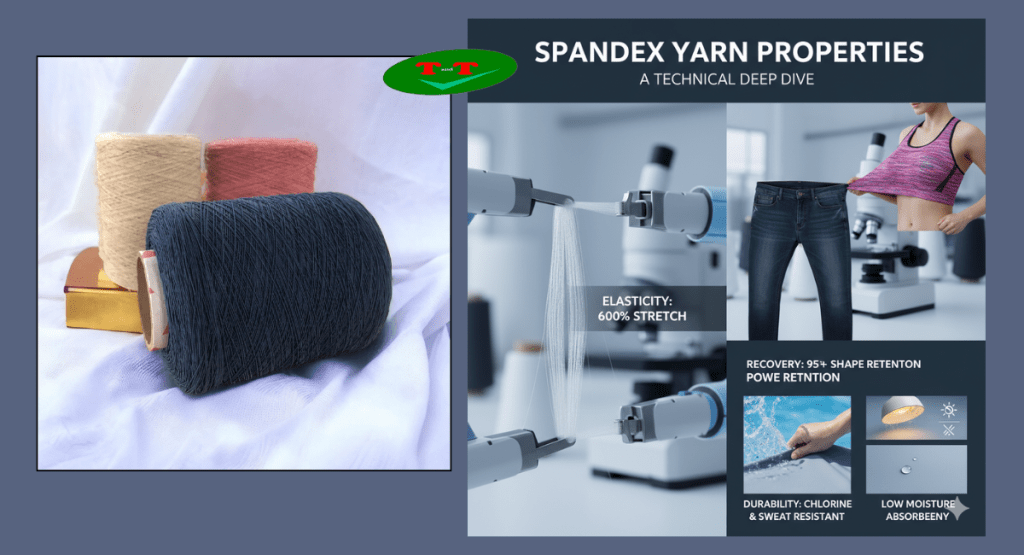

- Exceptional Elasticity and Elongation: This is the defining property. Spandex can consistently stretch to 500-600% of its original length without breaking, far exceeding the capacity of natural rubber.

- Superior Recovery Power: High-quality spandex yarn offers over 95% recovery after repeated stretching. This is critical for preventing bagginess in jeans and sagging in swimwear, ensuring lasting shape.

- High Tensile Strength: Despite its thin gauge, spandex filament possesses significant strength, with a tenacity typically ranging from 0.6 to 1.0 grams per denier, allowing it to withstand rigorous manufacturing and daily wear.

- Lightweight and Soft: Spandex yarn adds minimal weight and bulk to a fabric. Common deniers for apparel range from 20D to 140D, preserving drape and feel while imparting essential stretch.

Chemical and Resistance Properties

Understanding how spandex interacts with chemicals and environmental factors is vital for dyeing, finishing, and garment care.

- Good Resistance to Body Oils and Perspiration: This makes it ideal for activewear and intimate apparel, as it won’t degrade quickly from sweat and skin oils.

- Fair Resistance to Acids and Alkalis: It generally has better resistance to dilute acids than to alkalis. Processing conditions must be carefully controlled, as strong alkalis used in bleaching can cause degradation.

- Sensitivity to Heat and Light: Prolonged exposure to temperatures above 150°C (302°F) can cause yellowing and a loss of elasticity. This influences heat-setting during manufacturing and dictates lower-temperature washing.

- Chlorine Resistance: Specialized grades of spandex are engineered to offer good resistance to degradation from chlorinated water, which is essential for the longevity of swimwear.

Other Properties

- Low Moisture Absorbency: Spandex is hydrophobic, with a moisture gain of only about 1%, which helps fabrics dry quickly—a key benefit in sportswear.

- Abrasion Resistance: It contributes to the overall durability of a fabric, helping it withstand rubbing and wear over time.

Benefits of Spandex Yarn in Fabric Applications

The technical properties of spandex yarn translate directly into game-changing benefits for fabrics and end-use garments.

- Form-Fitting Comfort and Freedom of Movement: The combination of high elongation (500-600%) and excellent recovery (>95%) creates garments that move with the body without constricting. This is non-negotiable in activewear and yoga apparel.

- Shape Retention and Anti-Bagging: By consistently returning to its original shape, spandex ensures that garments like denim jeans and shapewear maintain their silhouette and compressive properties wash after wash.

- Enhanced Fit and Drape: Even a small percentage (2-5%) of spandex in a woven fabric can eliminate the rigid, boxy feel, allowing for better fit and a more flattering drape in tailored trousers and shirts.

- Seamless Construction Enabler: The fine denier and high stretch of spandex yarn are fundamental to the production of seamless garments, creating comfortable, chafe-free apparel with targeted support zones.

- Durability in Harsh Conditions: Its engineered resistance to chlorine and sunlight makes it critical in swimwear, while its strength and biocompatibility lend itself to uses in compression garments and medical textiles.

In essence, the integration of spandex yarn transforms static fabrics into dynamic, performance-driven materials. The core benefits can be summarized as the achievement of superior comfort through unmatched elasticity, long-term garment integrity via exceptional recovery, and expanded design possibilities for form-fitting and seamless applications.

Conclusion

Spandex yarn is far more than just a “stretch” ingredient; it is a sophisticated performance fiber whose properties are foundational to the comfort, fit, and functionality of modern textiles. From the gym to the runway, and from the beach to the medical clinic, its unique blend of mechanical resilience and chemical resistance continues to push the boundaries of what apparel can achieve. For industry professionals, a deep mastery of these spandex yarn properties is the key to unlocking the next generation of innovative, consumer-driven garments.

Ready to source high-quality spandex yarn for your next collection? Contact our expert team today to discuss your specific technical requirements and find the perfect stretch solution for your fabric needs.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com