Covered spandex yarn represents a revolutionary advancement in textile manufacturing, combining the exceptional elasticity of spandex with the protective covering of various fiber materials. This innovative yarn type has transformed the textile industry by offering enhanced durability, improved comfort, and superior performance characteristics. The unique manufacturing process involves wrapping spandex core yarn with other fibers, creating a versatile product that meets diverse applications across fashion, medical, and industrial sectors.

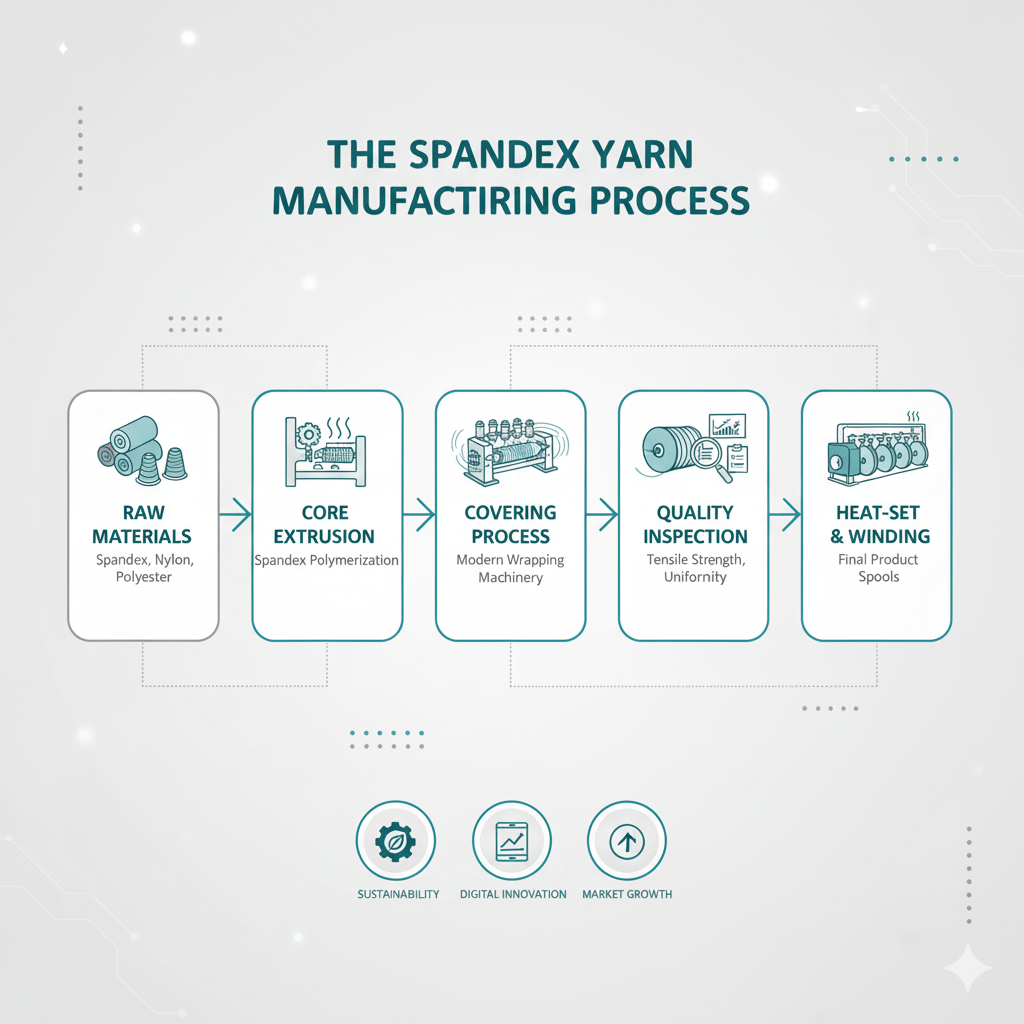

The Spandex Yarn Manufacturing Process

The journey of covered spandex yarn from raw materials to the final product is a complex and meticulously controlled process. Understanding the intricacies involved in this manufacturing procedure is essential for appreciating its impact on textile performance and quality.

Raw Materials Used in Production

The raw materials utilized in producing covered spandex yarn are foundational to its performance characteristics. The primary component, spandex, is chosen for its remarkable elasticity, allowing the fabric to stretch and recover without losing shape. Depending on the desired properties of the finished yarn, various covering fibers—such as nylon, polyester, or natural fibers—are selected based on their strength, aesthetic appeal, and functional capabilities.

The selection of these raw materials involves extensive research and development. Manufacturers conduct thorough tests to evaluate how different combinations work together, ensuring that the final product meets the required standards for durability, comfort, and stability. Innovations in fiber technology also play a role in enhancing raw material efficacy, as newer compositions may offer improved resilience against wear and tear while maintaining comfort.

The trend toward sustainability is influencing raw material choices, with a growing emphasis on using recycled fibers or sustainable sourcing practices. This conscientious approach not only addresses environmental concerns but also aligns with consumer preferences for eco-friendly products, driving growth in the market for sustainable textiles.

Steps Involved in the Manufacturing Process

The manufacturing process of covered spandex yarn encompasses several critical stages, each contributing to the yarn’s unique properties.

Initially, the spandex core is produced through a specialized extrusion process where polyether or polyester units are polymerized under strict temperature conditions to maximize elasticity. Following this, precise tension control is applied as this core is fed into a covering machine, where the covering material—which can vary according to the product specifications—is wrapped around it.

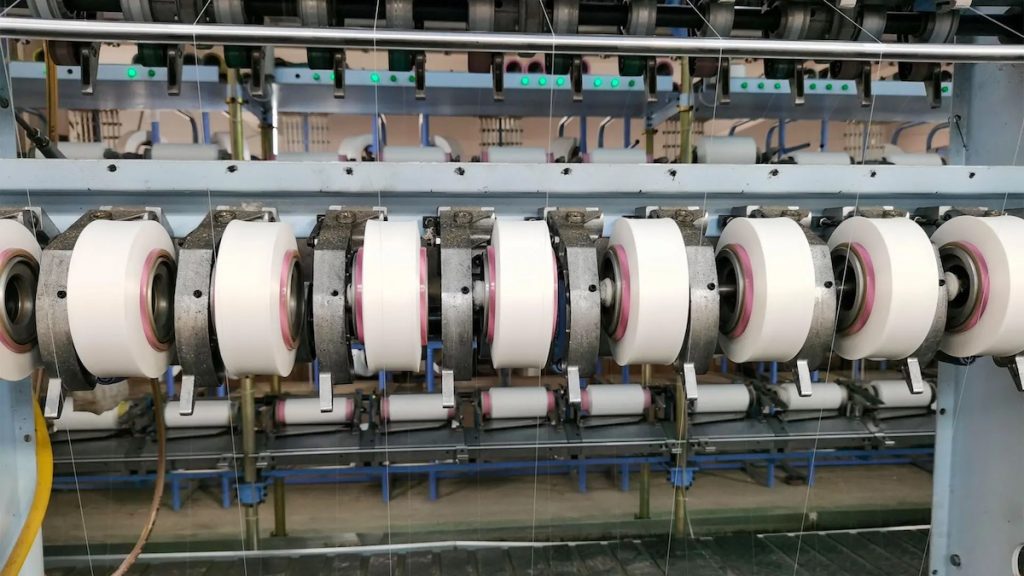

This wrapping process utilizes state-of-the-art machinery designed to ensure even and consistent coverage. The combination of both mechanical precision and advanced technology yields a yarn that achieves optimal stretch recovery, which is essential particularly in activewear and responsive textiles.

Once the covering process is complete, the yarn undergoes thorough inspection for consistency and quality. Any discrepancies are corrected before pressing forward, ensuring that what is eventually rolled out meets stringent industry standards. Final treatments, such as heat-setting and finishing processes, enhance the yarn’s surface qualities and overall durability.

Quality Control Measures During Production

Maintaining excellence during the production of covered spandex yarn is non-negotiable, requiring robust quality control measures throughout the manufacturing process. Comprehensive testing regimes are implemented at every stage, from fiber selection to final product assessment.

Various parameters are evaluated, such as tensile strength, elasticity, color fastness, and abrasion resistance. These tests aim to ensure that the yarn adheres to both industry standards and customer expectations, establishing a benchmark for quality.

Real-time monitoring systems are integrated into the manufacturing line to detect any anomalies early in the process. If abnormalities occur, they trigger an immediate analysis to identify root causes and minimize waste. This proactive quality control fosters efficiencies in production while preserving the integrity of the final product.

A culture of continuous improvement is supported by data analytics, where manufacturers can track performance metrics and incorporate learnings into future production runs, further enhancing the quality and reliability of covered spandex yarn.

Innovations in Manufacturing Techniques

As technology advances, so too does the manufacturing landscape for covered spandex yarn. Emerging innovations continuously reshape how yarns are produced, emphasizing both efficiency and performance enhancement.

One significant innovation is the adoption of digital technologies within the manufacturing process. Automation and computer-controlled machinery improve precision in covering processes, achieving uniformity and optimized performance. This technological shift also allows for greater customization, enabling manufacturers to swiftly adapt to changing market demands and trends.

Another noteworthy development includes advancements in eco-friendly dyeing techniques, minimizing water usage and hazardous chemical consumption while achieving vibrant color application. This is particularly relevant as the industry moves toward addressing environmental impacts associated with traditional processing methods.

Furthermore, developments in fiber technology have led to the introduction of multifunctional covered spandex yarns. These new variations exhibit properties such as moisture-wicking or anti-microbial features, catering not just to aesthetic desires but addressing health and wellness considerations for consumers. Such innovations highlight the evolution of covered spandex yarn beyond mere elasticity to encompass enhanced utility and performance attributes.

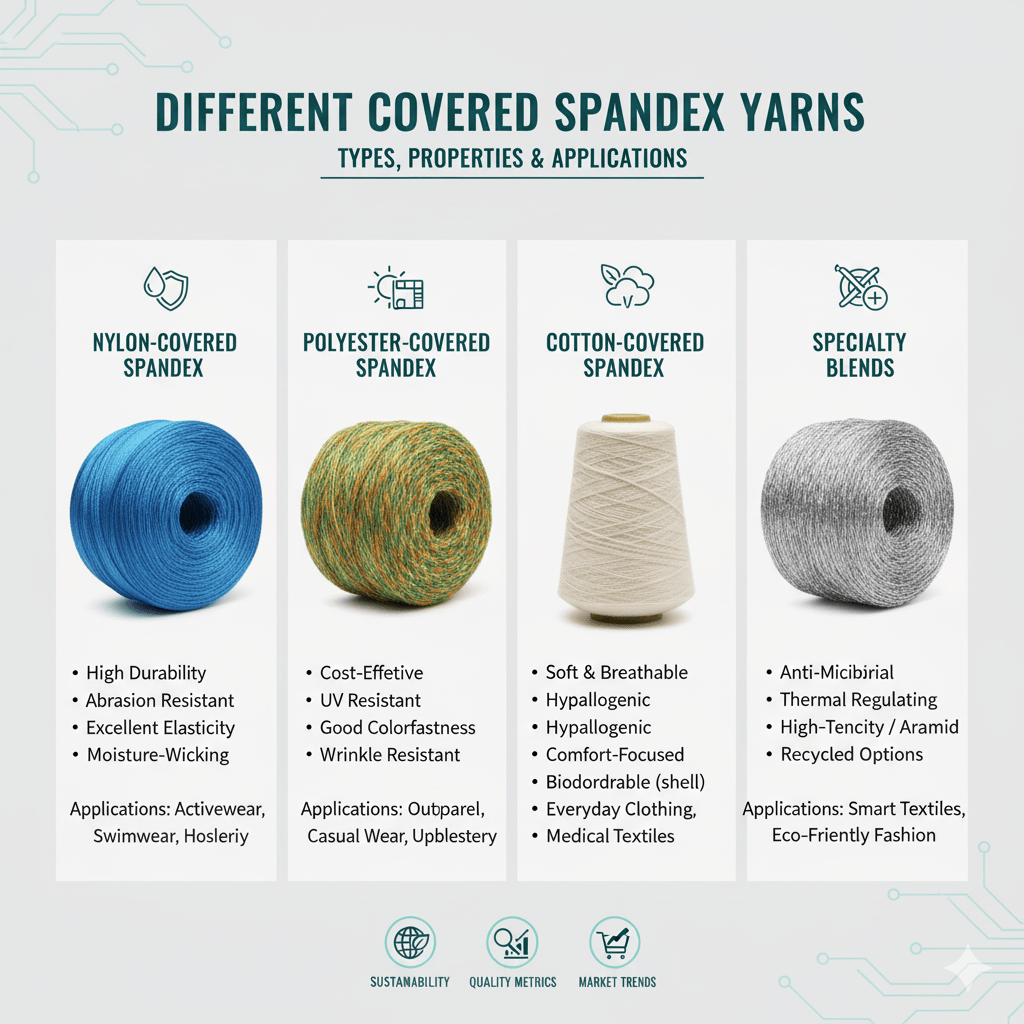

Comparison of Different Covered Spandex Yarns

With a variety of covered spandex yarn options available, understanding their distinctions is crucial for designers and manufacturers alike. Each type brings unique advantages and applications that cater to specific needs in the textile industry.

Durability and Performance Metrics

When evaluating covered spandex yarn types, durability and performance metrics emerge as pivotal factors for both manufacturers and consumers. The choice between various covered spandex constructions can significantly affect how fabrics perform over time, particularly under strenuous conditions.

Different covering materials contribute to differing levels of durability. For instance, nylon covered spandex yarn typically exhibits superior longevity and resistance to abrasions, making it suitable for high-performance activewear and protective gear. Conversely, softer fibers like cotton offer enhanced comfort, though they might compromise some durability.

Performance metrics such as elasticity retention, shrinkage rates, and overall tensile strength vary among yarn types. Understanding these metrics is paramount for manufacturers aiming to meet specific end-use requirements while delivering reliable and long-lasting textile solutions.

Cost Considerations and Market Trends

The cost of covered spandex yarn varies widely depending on fiber content, manufacturing complexity, and additional processing techniques employed. Polyester covered spandex yarn generally offers a more economical option than specialized air-covered or high-tenacity alternatives, but trade-offs may arise concerning performance.

Moreover, market trends play a crucial role in shaping producer strategies regarding yarn pricing and availability. As sustainable practices gain traction, there’s been a noticeable shift towards investing in recycled fibers, impacting the overall yarn cost structure. Moving forward, companies committed to eco-friendliness may be well-positioned to tap into emerging markets driven by consumer preference for sustainable sourcing.

Producers must therefore remain vigilant about fluctuating market dynamics and consumer demands while strategically managing resources and production methods to stay competitive in the ever-evolving textile marketplace.

Environmental Impact of Manufacturing Processes

Environmental stewardship is becoming increasingly relevant in textile manufacturing, and the production of covered spandex yarn is no exception. Manufacturers are focusing attention on reducing waste and minimizing the carbon footprint of their operations.

Innovative approaches include implementing closed-loop manufacturing processes and reducing water consumption, particularly in dyeing and treating stages. Many producers are exploring biodegradable alternatives and sustainable resources for raw materials, contributing positively to the team’s ecological footprint.

Additionally, industry awareness around circular economy principles is shifting focus towards lifecycle assessments of textiles. This holistic viewpoint sheds light on how covered spandex yarn performs beyond its initial application, emphasizing recyclability and the potential for secondary uses at the end of its life cycle.

Challenges in the Production of Covered Spandex Yarn

While the market for covered spandex yarn is promising, challenges persist that complicate its production and utilization. Addressing these hurdles effectively is crucial for maintaining competitiveness in a dynamic textile landscape.

Sourcing Sustainable Raw Materials

The shift towards eco-conscious manufacturing models presents complexities in sourcing sustainable raw materials for covered spandex yarn production. Gaining access to recycled or organic materials often poses significant logistical hurdles and cost implications that can deter manufacturers from fully committing to sustainable practices.

Auditing supplier chains to ensure responsible sourcing and transparency is an ongoing challenge many companies face, especially in regions where regulations may be lacking. Balancing affordability with sustainability requires strategic planning and collaboration with suppliers who share similar environmental priorities.

To combat these difficulties, organizations are increasingly exploring partnerships with environmental groups and stakeholders focused on advancing sustainable initiatives within the textile sector. By building alliances and developing shared standards, the industry can move toward sourcing materials that reflect personal and collective responsibility towards global environmental health.

Overcoming Technical Barriers in Manufacturing

Efficient covered spandex yarn production necessitates overcoming technical barriers inherent in balancing multiple fiber characteristics while preserving elasticity and comfort. Sophisticated machinery is required to execute the intricate covering process, but malfunction or operational inefficiencies can lead to subpar outputs.

Investments in advanced technologies, employee training, and skill enhancement are vital for navigating these challenges. Embracing innovation while focusing on human capital ensures manufacturers maintain production quality amid evolving market demands.

Research initiatives exploring new materials or covering techniques can lead to breakthroughs that address technical challenges. This area of exploration highlights the need for interdisciplinary collaboration among scientists and manufacturers to propel advancements in textile production further.

Addressing Consumer Preferences

Staying attuned to rapidly changing consumer preferences represents a significant challenge for manufacturers of covered spandex yarn. As awareness around sustainability increases, customers increasingly favor brands that prioritize eco-friendly practices, transparency, and ethical production.

Capturing the interest of conscious consumers necessitates a genuine commitment to adapt offerings that align with these values. This may mean reformulating materials, rethinking product lines, or enhancing marketing strategies to communicate brand mission transparently.

Furthermore, observing emerging trends such as athleisure wear and adaptive clothing introduces an additional layer of complexity when refining product offerings. Continuous engagement with consumers, including feedback mechanisms and trend analyses, can assist companies in successfully anticipating shifts and pivoting rapidly to meet market demands.

Future Trends in Covered Spandex Yarn Manufacturing

Looking ahead, various trends are poised to shape the future landscape of covered spandex yarn manufacturing, guided by technological advancements, sustainable practices, and evolving market dynamics.

Advances in Sustainable Practices

Sustainability will likely remain a central theme in the evolution of covered spandex yarn manufacturing. As consumers increasingly gravitate toward eco-friendly alternatives, manufacturers must prioritize innovative approaches that reduce resource consumption and waste.

Pioneering techniques such as closed-loop recycling, energy-efficient production methods, and biodegradable components suggest a shift in operational paradigms that echoes environmental responsibility. Collaborations with research institutions may further catalyze progress in identifying sustainable substances that enhance product performance.

By adopting sustainable practices, manufacturers not only contribute to environmental preservation but may simultaneously unlock new market opportunities that resonate deeply with ethically-minded consumers.

Technological Innovations Shaping the Industry

The textile sector will continue to benefit substantially from advancements in technologies that streamline production processes and elevate product quality. Breakthroughs in digital printing, smart textiles, and automation promise to revolutionize covered spandex yarn manufacturing.

Tech-driven solutions facilitate real-time adjustments and monitoring throughout the production process, allowing manufacturers to respond dynamically to fluctuations in demand while adhering to quality standards. Meanwhile, smart textiles imbued with sensors and functionalities are reshaping the concept of traditional fabrics, proposing value-additions to end-users that extend beyond aesthetic function.

Such transformations define a future where creativity marries capability, diversifying the potential applications and market segments accessible to covered spandex yarn.

Predictions for Market Growth and Demand

As the global emphasis on performance-oriented textiles persists, projections show notable growth in demand for covered spandex yarn across various sectors, including fashion, athletic wear, and technical applications.

Evolving consumer lifestyles continue to influence purchasing behaviors and expectations, heralding a strong appetite for versatile, high-performance fabrics. Companies positioned to adapt swiftly and innovatively will likely capture increased market share, leveraging covered spandex yarn‘s myriad advantages to meet contemporary demands.

Additionally, expansion into emerging markets may provide further avenues for growth as awareness of advanced textile technologies proliferates. By aligning offerings with customer preferences and addressing sustainability concerns, manufacturers have an opportunity to significantly drive demand within the global textile industry.

Conclusion

Covered spandex yarn has emerged as a transformative force in the textile sector, bridging innovation with functionality. Its unique composition, characterized by an elastic core wrapped in protective fibers, opens the door to diverse applications spanning fashion, activewear, medical textiles, and beyond.

As the industry embraces sustainability, technological advancements, and evolving consumer trends, the future holds tremendous potential for covered spandex yarn manufacturing. By addressing the challenges that accompany rapid change, manufacturers can harness opportunities that foster growth while remaining aligned with eco-conscientious practices.

The journey ahead is not simply about producing yarn; it’s about reimagining the very fabric of our lives and fostering connections between people, performance, and the planet.

Looking for reliable spandex yarn suppliers or optimized spandex blends for your product line? Contact us for technical support, application guidance, and competitive pricing.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread