Spandex yarn, also known as elastane, represents one of the most transformative innovations in modern textile history. This synthetic polymer is celebrated for its extraordinary elasticity, capable of stretching over 500% of its original length and recovering seamlessly.

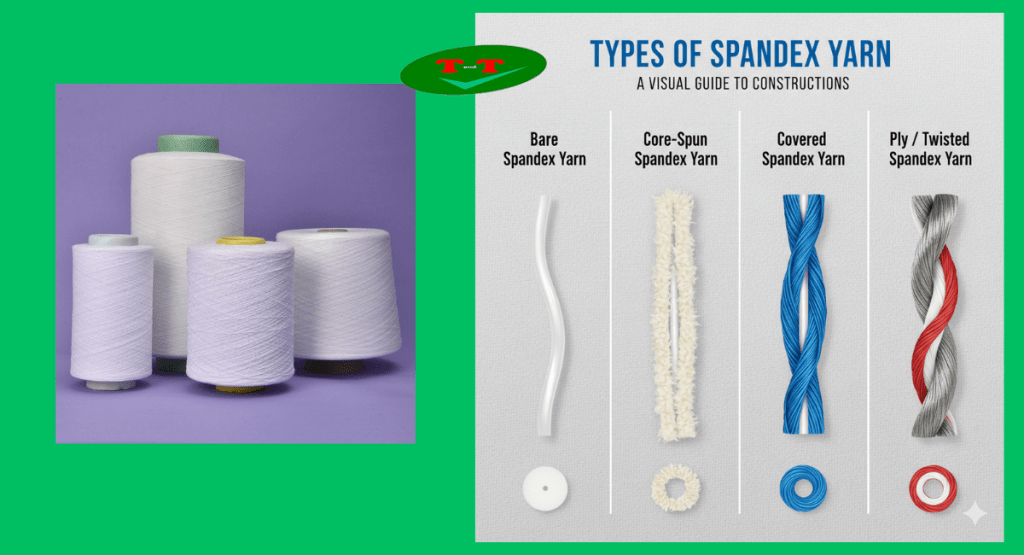

While bare spandex filament is rarely used alone, its true power is unlocked through various engineering processes that transform it into durable, processable spandex yarn. These constructions include core-spun, covered, and twisted yarns, each designed for specific performance characteristics.

The versatility of spandex yarn has revolutionized apparel and technical textiles, making it a fundamental component in everything from everyday comfort wear to high-performance gear. This article provides a comprehensive exploration of spandex yarn types, applications, and the future of elastic textiles.

Understanding Spandex Yarn: The Foundation of Stretch Fabrics

The journey of spandex yarn began in the 1950s when scientists sought to create a synthetic fiber with superior elasticity compared to natural rubber. Through decades of refinement, manufacturers have perfected the art of controlling denier, elasticity, and thermal stability to meet diverse industrial requirements. The fundamental properties that make spandex yarn indispensable include exceptional stretch and recovery, lightweight characteristics, dyeability, and compatibility with various fiber systems.

The true innovation lies in combining bare spandex with other materials to create optimized yarn structures. By integrating spandex with natural fibers like cotton and wool, manufacturers achieve the perfect balance between comfort and stretch. Synthetic combinations with polyester and nylon, particularly through advanced covering techniques, enhance durability and resistance to chemicals and abrasion. These strategic material partnerships allow spandex to maintain its elastic properties while gaining the surface characteristics and processing advantages of the companion fibers.

These advanced manufacturing techniques have transformed spandex from a delicate filament into a robust, versatile yarn suitable for various textile applications. The ability to precisely control parameters such as twist level, tension, and covering density ensures consistent performance across different production batches. This technical sophistication has enabled spandex yarn to become the invisible force behind modern comfort and performance in textiles.

Having established this foundational understanding of material combinations and manufacturing techniques, we can now explore the specific constructions that make diverse applications possible.

Exploring Different Types of Spandex Yarn Constructions

The versatility of spandex is largely due to the various engineering methods used to create workable yarns. Each construction offers unique properties tailored for specific end-uses, with innovations continuously expanding application possibilities.

Bare Spandex Yarn

- Definition: The pure, uncoated spandex filament in its most basic form.

- Composition: 100% spandex.

- Production: Directly extruded from the polymer solution.

- Key Properties: High stretch potential but poor resistance to abrasion and heat.

- Typical Applications: Primarily serves as the core component in covered or core-spun yarn production.

Core-Spun Spandex Yarn

- Definition: A yarn featuring a spandex core permanently surrounded by a sheath of staple fibers during spinning.

- Composition: Spandex core with a sheath of cotton, polyester, or other staple fibers.

- Production: Created on specialized ring spinning or rotor spinning frames.

- Key Properties: Combines spandex stretch with the surface characteristics of the sheath fiber.

- Typical Applications: Denim jeans, t-shirts, dress shirts, and casual wear.

Covered Spandex Yarn

- Definition: A construction where a spandex core is helically wrapped by one or two layers of another yarn.

- Composition: Spandex core covered by nylon, polyester, or cotton.

- Production: Manufactured using precise covering machines that control twist and tension.

- Key Properties: Excellent durability, spandex protection, and superior recovery.

- Typical Applications: Swimwear, intimate apparel, sportswear, and medical garments.

Ply / Twisted Spandex Yarn

- Definition: A yarn made by twisting a bare or covered spandex yarn with another yarn.

- Composition: Often combines spandex with textured filaments or other yarns.

- Production: Produced on twister or fancy twister machines.

- Key Properties: Bulkier hand, improved opacity, and unique visual texture.

- Typical Applications: Technical textiles, heavy knits, and specialty fabrics.

Comprehensive Applications of Spandex Yarn Across Industries

The versatility of spandex yarn extends across numerous sectors, with each industry leveraging its unique properties to enhance product performance and comfort. Below are the key application areas with specific product examples:

Fashion and Daily Wear

The fashion industry has been fundamentally transformed by the integration of spandex yarn, which has redefined the relationship between style and comfort.

In the denim sector, the incorporation of just 2-3% spandex content has enabled the creation of skinny jeans and jeggings that maintain their shape through repeated wear while providing unprecedented comfort and freedom of movement.

This same revolutionary approach applies to woven shirts and blouses, where minimal spandex addition allows for tailored dress shirts and stretch blouses that accommodate natural movement without compromising their structured appearance.

The influence extends to dresses and outerwear, where stretch wool blends create elegant garments that move with the wearer while retaining their sophisticated silhouette.

Even in formal wear and accessories, spandex integration has enabled designers to create pieces that combine aesthetic appeal with practical comfort.

Activewear and Sportswear

The activewear sector represents one of the most significant applications of advanced spandex yarn technologies, where performance demands push material capabilities to their limits.

In athletic bottoms, specialized spandex constructions enable yoga pants and running tights to provide multidirectional stretch that supports complex movements while offering muscle compression and reducing fatigue.

The upper body garment category utilizes compression shirts and athletic jerseys that enhance athletic performance. These garments improve blood circulation and moisture management during intense physical activity.

For sport-specific applications, competitive swimwear and cycling shorts benefit from spandex’s unique properties. The material offers chlorine resistance, reduced water absorption, and superior aerodynamic properties.

The sector also includes essential accessories like sports bras and performance socks. These provide targeted support and comfort during high-intensity activities, ensuring optimal performance and protection.

Intimate Apparel and Hosiery

In the intimate apparel and hosiery sector, spandex yarn serves as the fundamental component that balances delicate comfort with structural integrity.

The lingerie category relies on precisely engineered spandex for bras and panties. These offer gentle yet consistent support throughout daily wear, combining comfort with functionality.

Shapewear and foundation garments demand more robust spandex constructions. Body shapers and corsetry provide firm control without sacrificing comfort or breathability, enhancing the wearer’s silhouette.

The hosiery segment utilizes fine-denier spandex yarns to create sheer pantyhose and medical stockings. These deliver powerful compression while maintaining a virtually invisible appearance.

Even in sleepwear and loungewear, spandex integration enables stretch pajamas and nightgowns to provide all-night comfort without any restrictive feeling.

Medical and Healthcare Textiles

The medical and healthcare sector represents one of the most technically demanding applications for spandex yarn, where performance directly impacts patient outcomes and therapeutic effectiveness.

Compression therapy utilizes precisely calibrated spandex yarns in surgical stockings and anti-embolism stockings. These deliver specific pressure gradients that promote circulation and prevent blood clots.

Orthopedic applications depend on the consistent recovery properties of medical-grade spandex. Athletic braces and joint supports maintain proper alignment while allowing necessary movement for recovery.

The therapeutic garment category includes post-surgical garments and burn recovery clothing. These use controlled compression to reduce swelling and support tissue healing during critical recovery periods.

These medical applications demand the highest levels of quality control and performance consistency. Manufacturers must adhere to strict medical device regulations and standards to ensure patient safety and product efficacy.

Technical and Industrial Textiles

Beyond traditional apparel applications, spandex yarn has become an engineering material that solves complex challenges across various industrial sectors.

The automotive industry incorporates spandex-enhanced fabrics for car seat covers and interior panels. These provide comfortable conformity while withstanding years of heavy use and environmental stress.

Furniture manufacturing utilizes spandex integration in upholstery fabrics and fitted covers. These maintain their appearance and fit through repeated stretching and cleaning cycles, ensuring long-term durability.

The protective equipment sector employs spandex in technical workwear and safety apparel. This ensures worker mobility without compromising protection standards in demanding industrial environments.

Emerging applications also include aerospace textiles and marine upholstery. In these challenging environments, spandex’s durability and elastic recovery provide critical performance advantages where failure is not an option.

The widespread adoption of spandex yarn across these diverse industrial sectors demonstrates its unique capability to enhance functionality while maintaining comfort. From high-fashion runways to medical facilities and advanced industrial settings, the controlled elasticity and reliable recovery of spandex continue to drive product innovation and performance improvements across global markets.

Future Innovations in Spandex Yarn Technology

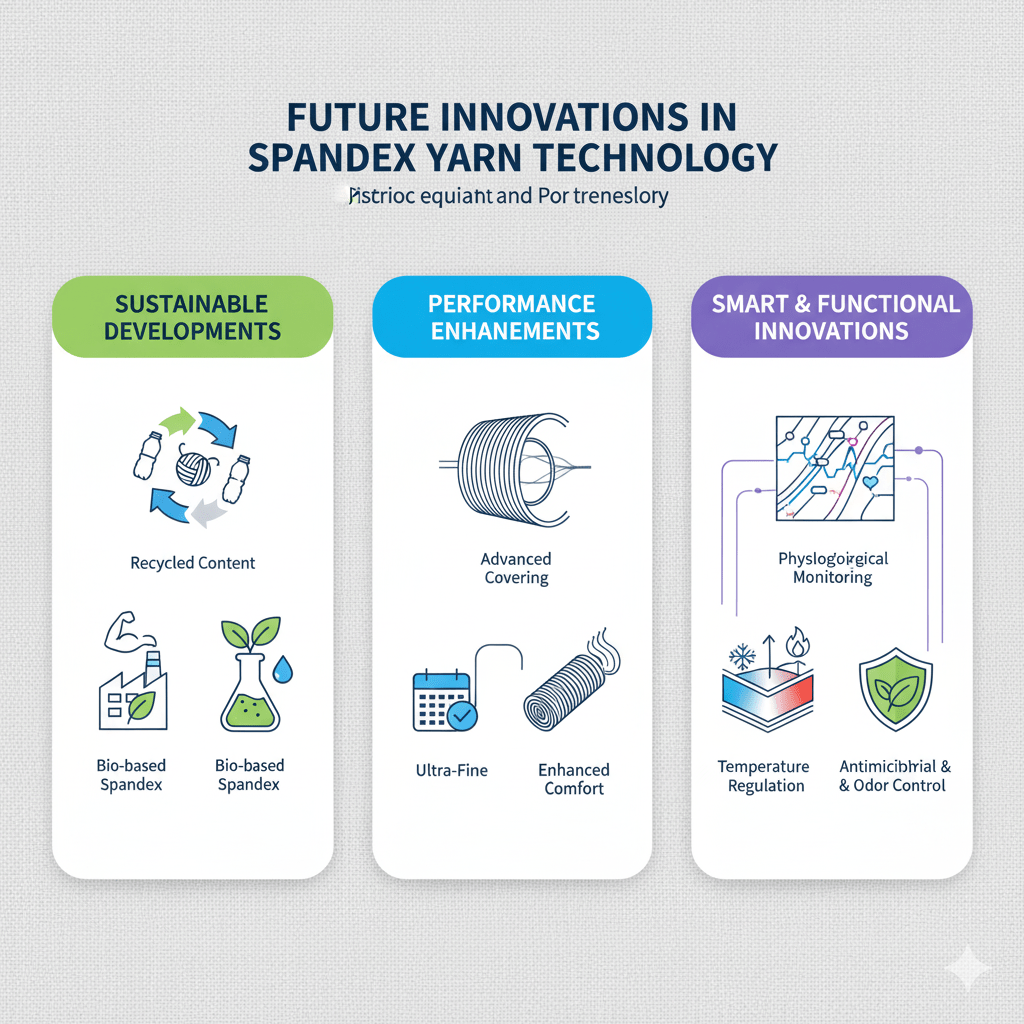

Sustainable Developments

The textile industry is witnessing a profound shift toward sustainability, and spandex yarn production is at the forefront of this transformation. This movement represents one of the most significant changes in the industry’s environmental approach.

Manufacturers are actively embracing circular economy principles through innovative material solutions. A key development is the creation of recycled content yarns that incorporate post-consumer materials, with notable progress in nylon and polyester covering systems.

Beyond recycling, the industry is exploring more fundamental changes in raw material sourcing. The emergence of bio-based spandex alternatives derived from renewable resources marks a pivotal shift away from traditional petroleum-based production.

These material innovations are supported by advances in manufacturing processes. Cleaner production methods that significantly reduce chemical usage and energy consumption are being implemented across the industry.

The collective impact of these ecological advancements addresses environmental concerns throughout the entire product lifecycle. Importantly, these sustainable innovations maintain the high performance standards that industries and consumers demand.

Performance Enhancements

Alongside sustainability initiatives, the industry is achieving remarkable advances in performance characteristics. Modern spandex yarn manufacturing is reaching unprecedented levels of precision and capability.

Advanced covering technologies represent a major breakthrough. These systems now produce yarns with exceptional consistency in denier, elasticity, and recovery properties, ensuring more predictable processing and end-product performance.

Manufacturers are developing increasingly specialized constructions to meet specific application needs. The market now offers high-resistance yarns for compression garments alongside ultra-fine variants designed for sheer hosiery applications.

Durability improvements constitute another area of significant progress. Enhanced characteristics now prolong product lifespan while maintaining elastic properties through extended use.

Comfort features have also seen substantial innovation. New yarn constructions make spandex-containing garments suitable for extended wear across various environmental conditions, expanding their practical applications.

Smart and Functional Innovations

The integration of smart technologies opens exciting new possibilities for spandex yarn applications. This represents the next frontier in textile innovation and functionality.

Research institutions and manufacturers are pioneering the development of smart yarn structures. They’re exploring ways to embed sensor technologies directly into yarn, creating fabrics capable of monitoring physiological data for healthcare and sports performance.

Temperature regulation is another area of active innovation. The incorporation of phase-change materials and advanced moisture-management systems enables the creation of thermoregulating textiles that respond to body temperature and environmental conditions.

Hygiene and freshness features are being fundamentally reengineered. Permanent antimicrobial and odor-control properties are now being integrated into spandex yarns at the molecular level.

These smart innovations are significantly expanding the utility of spandex yarns. Their applications now extend beyond traditional uses into medical, athletic, and everyday applications where hygiene and freshness are paramount concerns.

Conclusion

The journey of spandex yarn from a specialized innovation to a textile industry staple demonstrates its fundamental importance in modern manufacturing. Its unique ability to provide controlled elasticity while maintaining comfort and durability has made it indispensable across fashion, sportswear, medical textiles, and technical applications. As consumer expectations evolve and sustainability becomes increasingly crucial, the ongoing innovation in spandex yarn technology will continue to drive new possibilities in textile design and functionality, ensuring its relevance for years to come.

For manufacturers and designers, success in today’s competitive market requires a thorough understanding of spandex yarn options and their specific performance characteristics. The key lies in selecting the appropriate yarn construction that aligns with your product’s functional requirements, quality standards, and sustainability goals. By mastering the nuances of different spandex yarn types and their optimal applications, brands can create products that truly meet consumer needs while maintaining competitive advantage.

Ready to explore the right spandex yarn solution for your product line? Contact our technical experts today for personalized consultation, comprehensive specifications, and sample requests. Let us help you select the perfect elastic yarn to enhance your product’s performance and comfort.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com