Understanding yarn weight is fundamental to the success of any textile project, from hand-knitting to industrial manufacturing. This critical specification determines not only the gauge and drape of the final fabric but also impacts production efficiency, material cost, and product performance.

This comprehensive guide demystifies the standard yarn weight system, providing a clear framework for selecting the perfect yarn for your specific application, whether you’re a designer, manufacturer, or fiber artist.

Standard Yarn Weight System

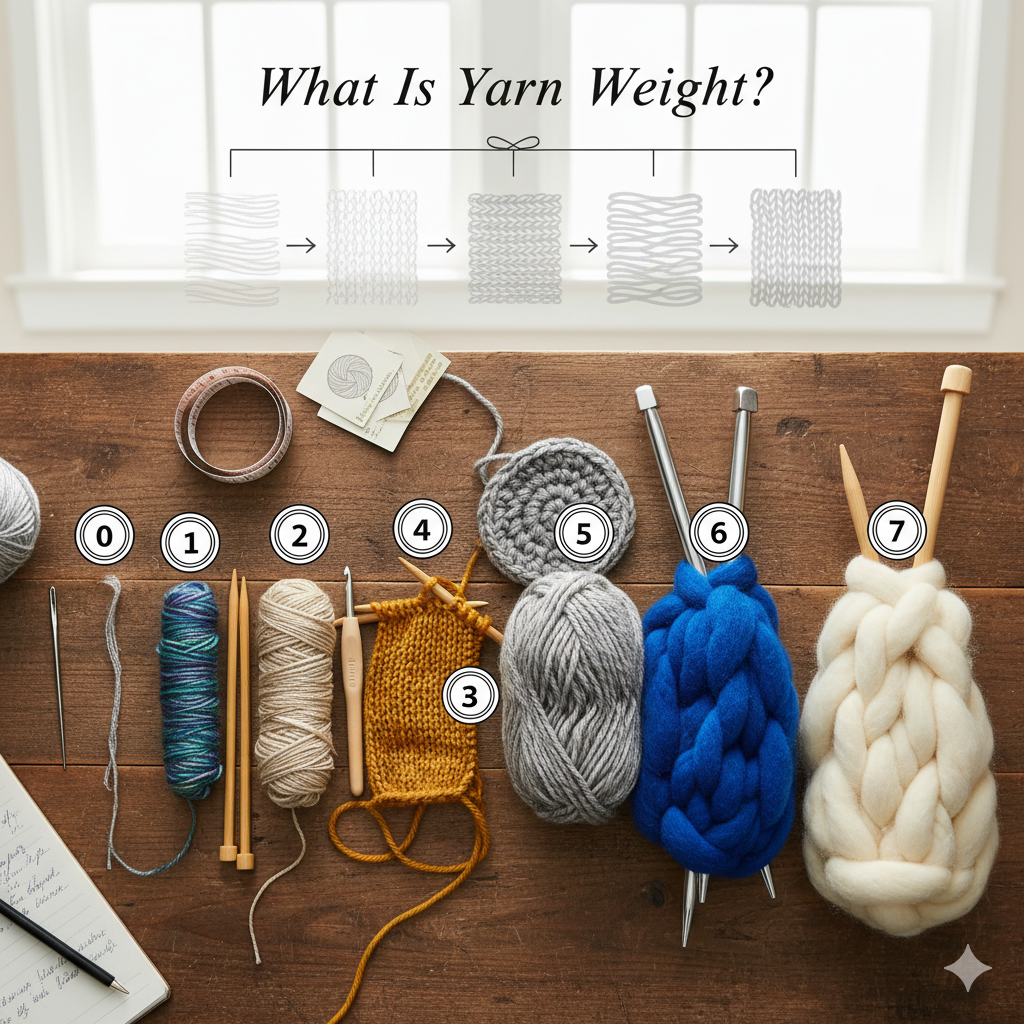

What Is Yarn Weight?

In textile terminology, “yarn weight” does not refer to the physical mass on a scale. Instead, it categorizes the thickness or diameter of a yarn strand. It is a standardized classification that groups yarns with similar thickness, which directly correlates to the gauge (number of stitches and rows per inch) and the resulting fabric’s characteristics.

The role of yarn weight extends beyond simple categorization – it serves as the fundamental blueprint for project planning. It directly influences:

- Fabric density and structure

- Production speed and efficiency

- Material consumption and cost

- Final product drape and warmth

- Suitable applications and end-uses

Selecting the correct yarn weight is the first and most crucial step in ensuring a project meets its intended design, fit, and function.

Who Defines the Standard Yarn Weight System?

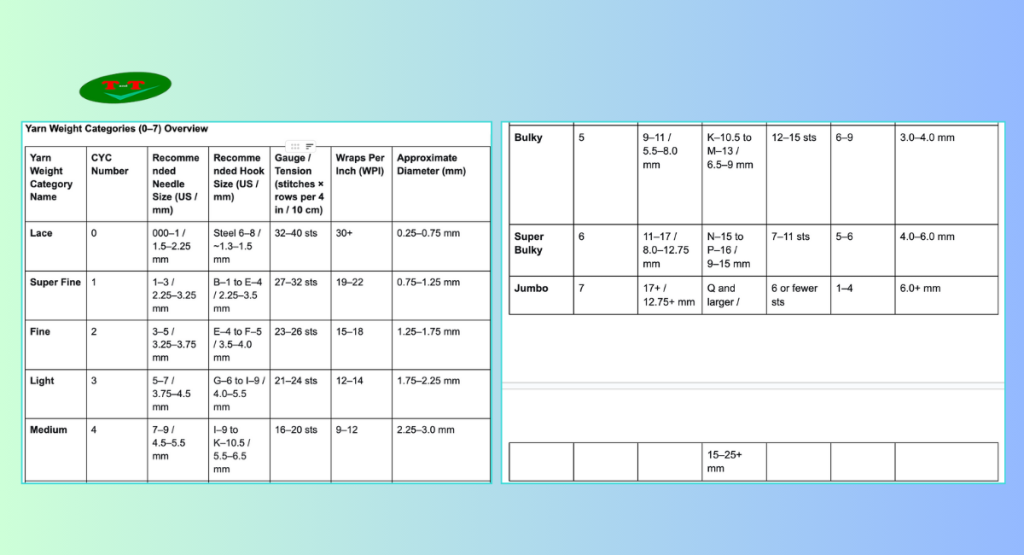

The most widely recognized framework is the Standard Yarn Weight System maintained by the Craft Yarn Council (CYC). This system has been adopted globally by yarn manufacturers, publishers, and designers to ensure consistency and clear communication across patterns and product lines. The CYC provides detailed specifications for each weight category, including recommended gauge, needle size, and hook size, creating a universal language for the industry.

Standard Yarn Weight Guide

Choosing a yarn weight is one of the most impactful decisions in a project. It fundamentally shapes the final outcome by determining the fabric density and gauge, influencing how many stitches are needed per inch. It directly affects production speed, as thicker yarns work up faster than thinner ones. The weight also dictates the fabric’s drape and warmth; lace-weight yarns create light, airy fabrics, while super bulky weights produce dense, heavy, and warm materials. Finally, it is key to the final structure and durability, with heavier weights generally yielding more robust fabrics suited for high-wear items.

To make informed decisions, let’s examine the complete specifications across all standardized categories in the comprehensive reference table below. This detailed breakdown will provide you with the essential technical parameters needed to select the perfect yarn weight for your specific application.

Yarn Weight Categories (0–7) Overview

| Yarn Weight Category Name | CYC Number | Recommended Needle Size (US / mm) | Recommended Hook Size (US / mm) | Gauge / Tension (stitches × rows per 4 in / 10 cm) | Wraps Per Inch (WPI) | Approximate Diameter (mm) |

| Lace | 0 | 000–1 / 1.5–2.25 mm | Steel 6–8 / ~1.3–1.5 mm | 32–40 sts | 30+ | 0.25–0.75 mm |

| Super Fine | 1 | 1–3 / 2.25–3.25 mm | B–1 to E–4 / 2.25–3.5 mm | 27–32 sts | 19–22 | 0.75–1.25 mm |

| Fine | 2 | 3–5 / 3.25–3.75 mm | E–4 to F–5 / 3.5–4.0 mm | 23–26 sts | 15–18 | 1.25–1.75 mm |

| Light | 3 | 5–7 / 3.75–4.5 mm | G–6 to I–9 / 4.0–5.5 mm | 21–24 sts | 12–14 | 1.75–2.25 mm |

| Medium | 4 | 7–9 / 4.5–5.5 mm | I–9 to K–10.5 / 5.5–6.5 mm | 16–20 sts | 9–12 | 2.25–3.0 mm |

| Bulky | 5 | 9–11 / 5.5–8.0 mm | K–10.5 to M–13 / 6.5–9 mm | 12–15 sts | 6–9 | 3.0–4.0 mm |

| Super Bulky | 6 | 11–17 / 8.0–12.75 mm | N–15 to P–16 / 9–15 mm | 7–11 sts | 5–6 | 4.0–6.0 mm |

| Jumbo | 7 | 17+ / 12.75+ mm | Q and larger / 15–25+ mm | 6 or fewer sts | 1–4 | 6.0+ mm |

Detailed Breakdown by Yarn Weight

- 0 – Lace: Lace weight yarn creates delicate, ethereal fabrics with excellent stitch definition. Typical fiber types include merino wool, silk, cashmere, and luxury blends. Common uses feature intricate shawls, fine doilies, delicate edgings, and lightweight summer garments that require exceptional drape and sophistication.

- 1 – Super Fine: This weight produces lightweight yet durable fabrics with excellent stitch clarity. Typical fibers encompass merino wool, bamboo, silk blends, and nylon-reinforced sock yarns. It’s ideal for fine-gauge garments including socks, delicate baby wear, lightweight sweaters, and heirloom-quality accessories that demand both beauty and durability.

- 2 – Fine (Sport): Sport weight offers versatility for creating substantial yet lightweight fabrics. Common fiber types include cotton, wool, acrylic, and blended yarns. Typical applications include light sweaters, baby garments, lighter-weight accessories, and transitional season wear that requires both warmth and breathability.

- 3 – Light (DK): DK weight serves as the perfect balance between drape and warmth. Typical fibers feature wool, cotton, acrylic, and alpaca blends. This workhorse weight is excellent for year-round sweaters, scarves, blankets, and accessories that require good stitch definition while providing moderate warmth and excellent drape characteristics.

- 4 – Medium (Worsted): Worsted weight is the most versatile and widely available category. Common fiber types include wool, acrylic, cotton, and all-purpose blends. It’s ideal for a vast range of projects including sweaters, hats, scarves, afghans, and home decor items that require durability, good stitch definition, and moderate working time.

- 5 – Bulky: Bulky weight creates warm, cozy fabrics with quick production time. Typical fibers encompass wool, wool blends, chunky acrylic, and novelty yarns. Perfect for cold-weather accessories like hats, scarves, blankets, and quick-to-knit sweaters that prioritize warmth and efficiency over fine detail.

- 6 – Super Bulky: Super bulky yarn produces extremely thick, warm fabrics with rapid completion time. Common fiber types include wool, wool blends, and heavy acrylics. Ideal for very warm items like heavy blankets, rugs, outerwear, and statement accessories where texture and speed outweigh detailed stitch work.

- 7 – Jumbo: Jumbo weight creates extreme texture and works up fastest of all categories. Typical fibers feature roving-style wool, super chunky acrylic, and novelty materials. Primarily used for arm knitting, giant needles for statement pieces like extreme chunky blankets, baskets, and oversized home decor items.

Conclusion

Yarn weight serves as the critical foundation for successful textile projects, influencing everything from fabric characteristics to production efficiency. Understanding the detailed specifications of each weight category – from delicate lace to substantial jumbo – enables precise selection for any application. By systematically evaluating project requirements and avoiding common pitfalls, manufacturers and designers can optimize their material choices for both quality and commercial success.

TANI THREAD specializes in supplying premium covered yarn to the U.S. market. If you have any requirements, please contact us today for expert consultation and detailed information.

TANI THREAD CO., LTD

- Address: Thanh Hoa Hamlet, Thanh Dien Commune, Chau Thanh District, Tay Ninh Province, Vietnam

- Hotline: 0984.841.239

- Email: sale@tanithread.com

- Website: tanithread.com

- Fanpage: Tani Thread